- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Undercarriage Spare Parts

-

Quality:

-

100% Professional Test

-

Certification:

-

IOS9001

-

MOQ:

-

1pcs

-

Delivery:

-

1-15 Working Days

-

Shipment:

-

Sea.Air.Express

-

OEM:

-

Avaliable

-

Application:

-

Undercarriage Parts

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

EG

-

Part name:

-

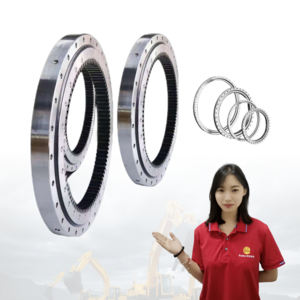

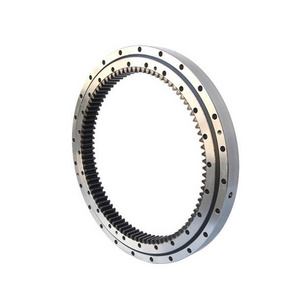

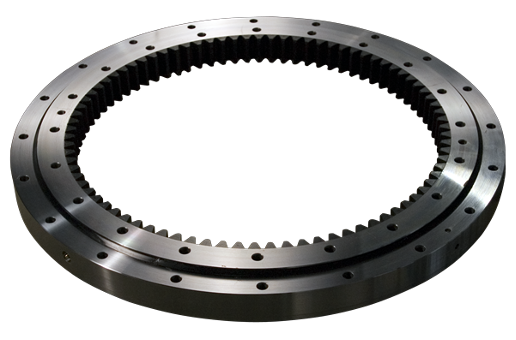

Swing Bearing

-

Type:

-

Undercarriage Spare Parts

-

Quality:

-

100% Professional Test

-

Certification:

-

IOS9001

-

MOQ:

-

1pcs

-

Delivery:

-

1-15 Working Days

-

Shipment:

-

Sea.Air.Express

-

OEM:

-

Avaliable

-

Application:

-

Undercarriage Parts

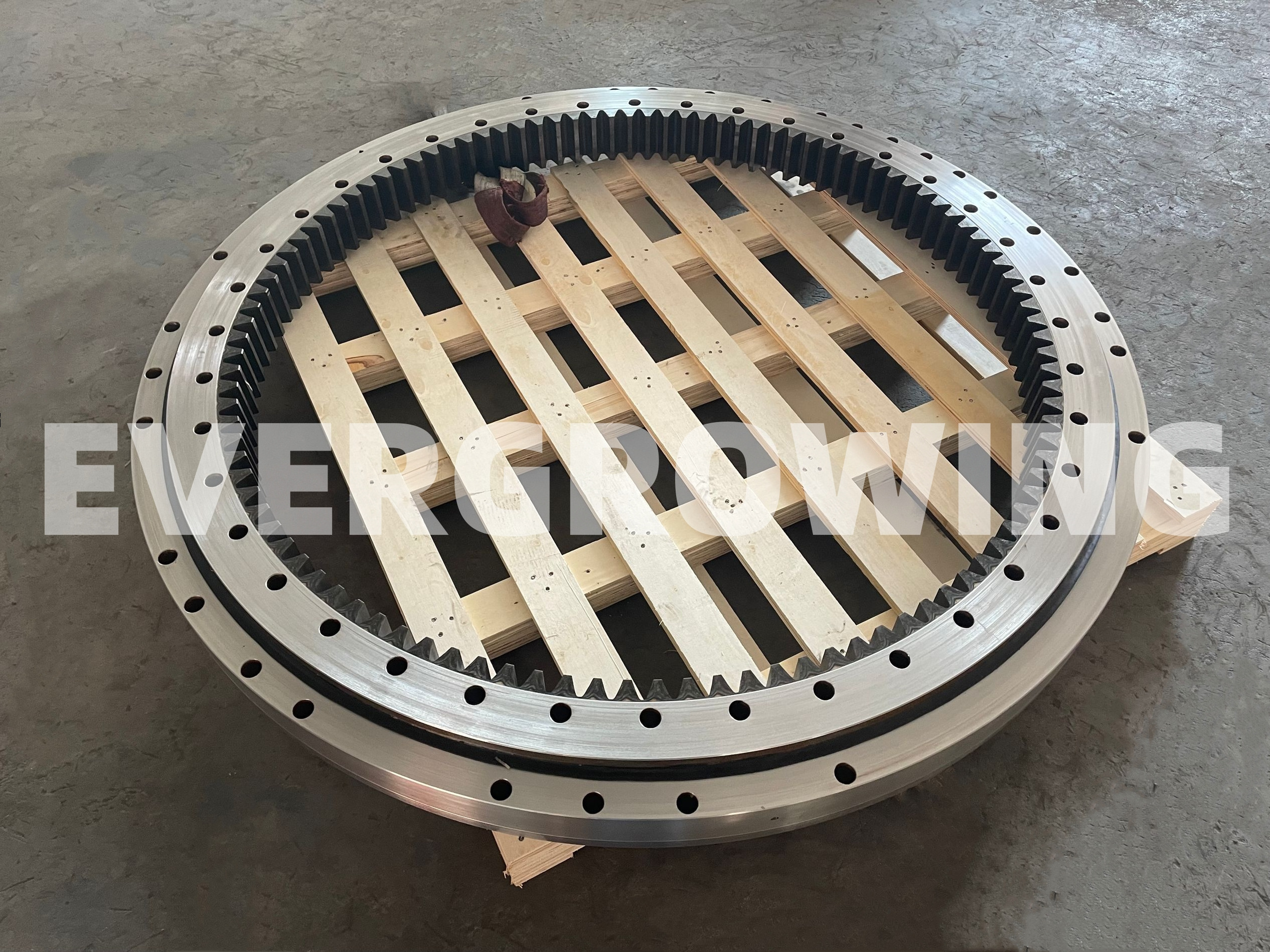

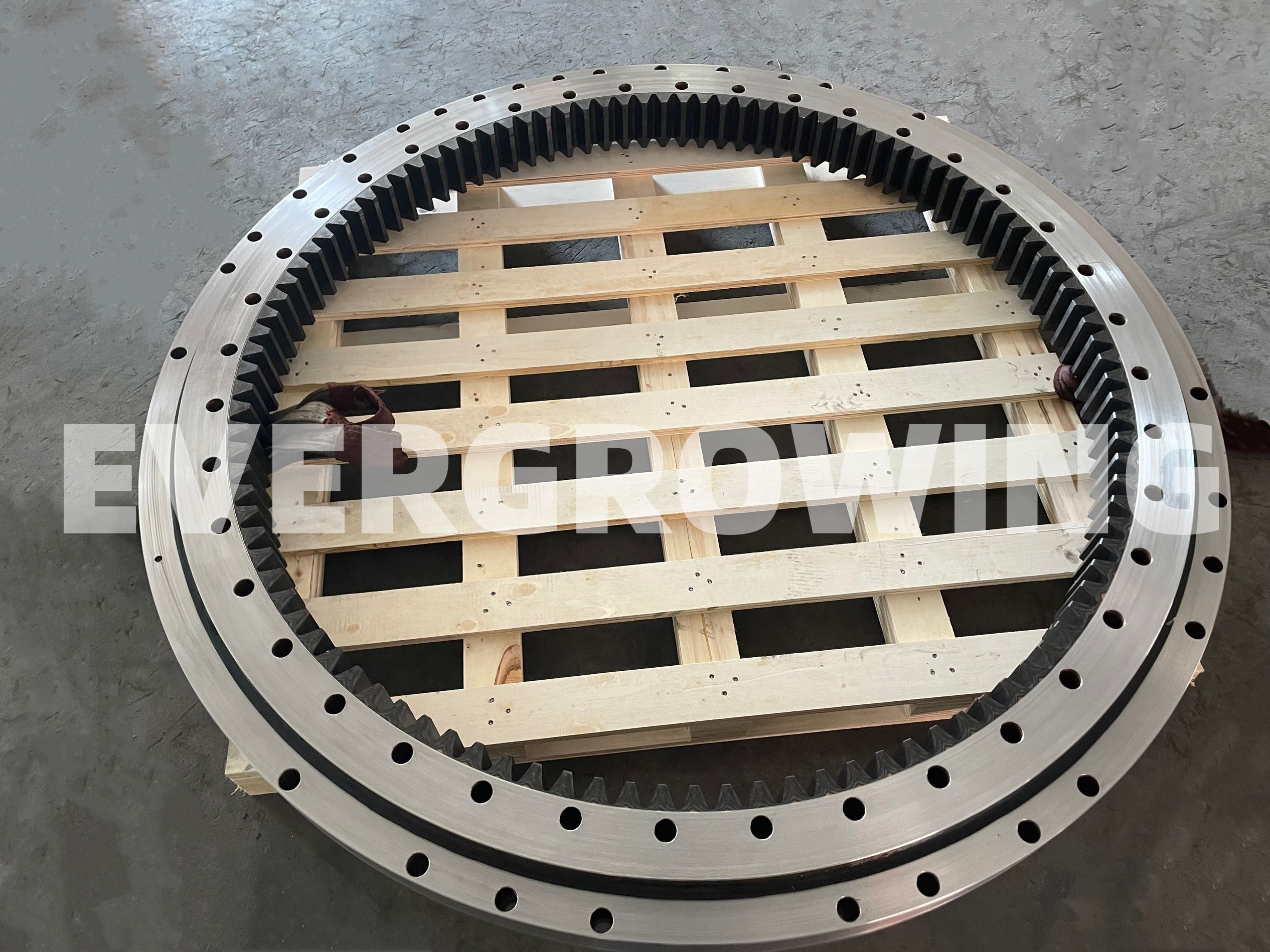

Details Images

|

Product

|

Swing Bearing

|

|

Warranty time

|

1 years / 2500 working days

|

|

Certification

|

SGS, ISO9001

|

|

FOB Price

|

Negotiate

|

|

MOQ

|

1 PCs

|

|

Delivery Time

|

15-25days after payment

|

|

Package

|

Pallet / Plywood Case

|

|

Payment Term

|

TT; LC; Negotiate

|

PRODUCTION PROCESS

Material selection: Slewing bearings are usually made of high quality alloy steel as raw material to ensure its strength and durability.

Drilling: The raw material is first drilled for subsequent processing.

Heat treatment: After drilling, the parts need to be heat treated to improve their hardness and wear resistance.

Machining and molding: the heat-treated parts need to be turned, milled and ground, and other machining processes, and finally formed into a slewing bearing parts.

Assembly: the processed parts are assembled and sealed and lubricated to ensure the normal operation of the slewing bearing.

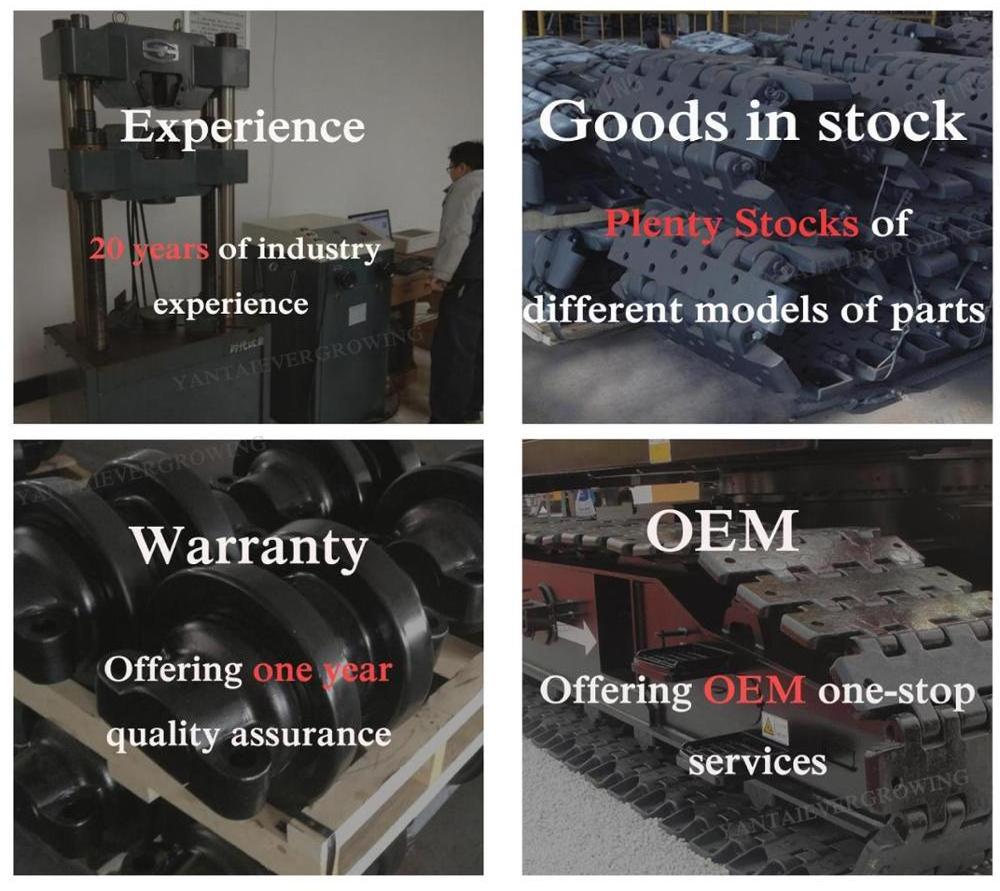

Why Choose Us

Strong bearing capacity: the slewing bearing is made of high-quality alloy steel, which has strong bearing capacity and can bear the weight and working load of the machine superstructure.

Flexible rotation: the slewing bearing has a smooth rotation performance, which can ensure that the upper structure of the machine has a flexible rotation performance in the work, and improve the work efficiency.

Wear-resistant and durable: the heat-treated and processed slewing bearing has good wear-resistance and durability, which can ensure stable operation for a long time.

Contact Us

Hot Searches