- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

customised

-

Voltage:

-

customized

-

Power:

-

1.5 Kw

-

Weight (KG):

-

4200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

wood briquettes carbonization furnace

-

Capacity:

-

4.5-6t/day

-

Raw material:

-

wood, log, coconut shell, nuts shell ,bamboo etc

-

Carbonization time:

-

8 Hours

-

cooling time:

-

6hours

-

Fuel:

-

raw coal, firewood, natural gas etc

-

Inner stove qty:

-

9 sets

-

Outer stove qty:

-

3 sets

-

Type:

-

Hoist and gas flow

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Effective Volume:

-

2.75*9CBM

-

Dimension(L*W*H):

-

customised

-

Voltage:

-

customized

-

Power:

-

1.5 Kw

-

Weight (KG):

-

4200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

wood briquettes carbonization furnace

-

Capacity:

-

4.5-6t/day

-

Raw material:

-

wood, log, coconut shell, nuts shell ,bamboo etc

-

Carbonization time:

-

8 Hours

-

cooling time:

-

6hours

-

Fuel:

-

raw coal, firewood, natural gas etc

-

Inner stove qty:

-

9 sets

-

Outer stove qty:

-

3 sets

-

Type:

-

Hoist and gas flow

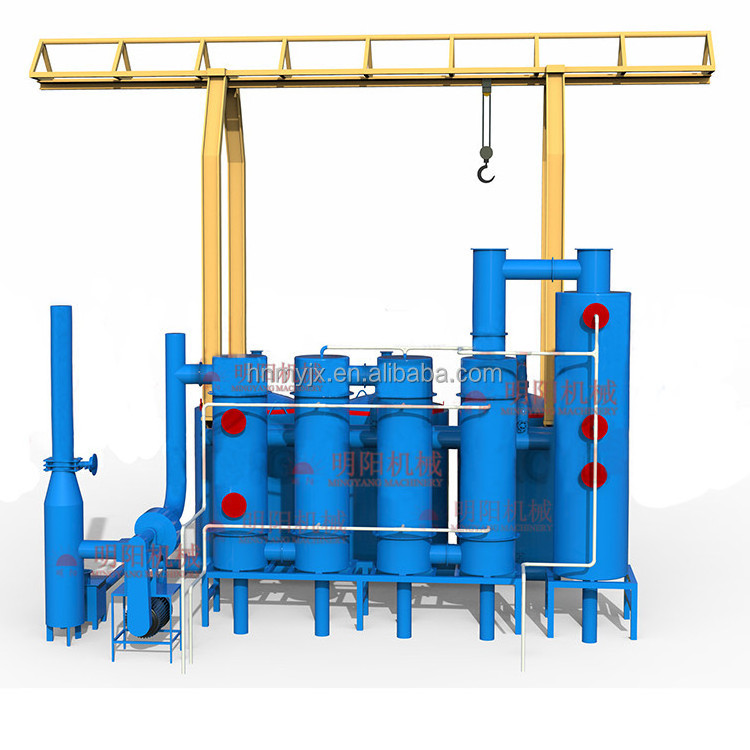

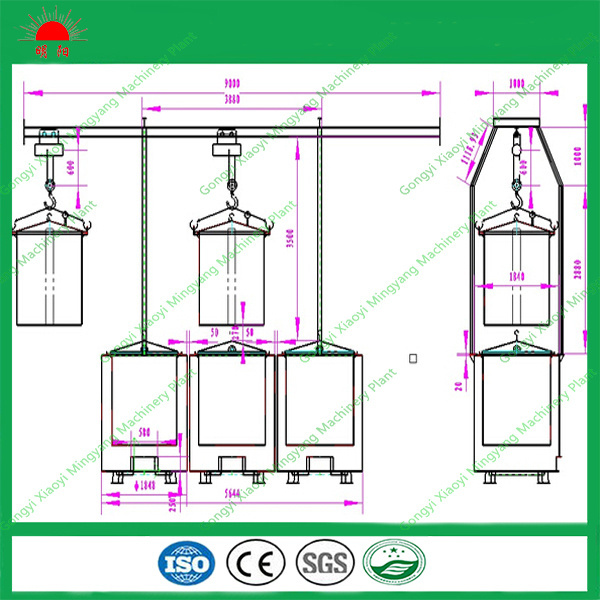

Hoist cylinder type wood briquettes carbonization furnace/lump charcoal making kiln/bamboo carbonized stove

1. Main data of the wood briquettes carbonization furnace:

| model |

capacity t/24h |

inner volume |

temperature Degree |

machine include |

| QHL-1 | 1.5-2 | 2.75*3CBM | 400-600 | 1outer stove, 3inner stoves with 3 caps, 1 3ton lifting device, 1smoking tank |

| QHL-2 | 3-4 | 2.75*6CBM | 400-600 | 2 outer stove, 6 inner stoves with 6 caps, one 5-ton hoisting equipment with e-motor, 1smoking tank |

| QHL-3 | 4.5-6 | 2.75*9CBM | 400-600 | 3 outer stove, 9 inner stoves with 9caps, one 5-ton hoisting equipment with e-motor, 1smoking tank |

| QHL-4 | 6-8 | 2.75*12CBM | 400-600 | 4 outer stove, 12 inner stoves with 12caps, one 5-ton hoisting equipment with e-motor, 4smoking tank |

2. How to operate our wood briquettes carbonization furnace:

A: put the raw material into the inner stove neatly;

B: use the hoist to hang the inner stove into the outer stove;

C: use the hoist to hang the caps to seal the inner stove with outer stove;

D: fire the outer stove and then to make the charcoal.

3. Introduction of the wood briquettes carbonization furnace:

Our wood briquettes carbonization furnace are included inner stove, when one inner stove are finished, it can be hoisted outside,. And when the first inner stove are cooling , the other inner stove can be carbonized at the same time, in this way the cooling time can be reduced much, thus, the productive efficiency increase a lot .This type of stove adopts the structure of unique air storage chamber, to fully reuse the smoke produced during the process of carbonization. And the redundant smoke can be used in drying and carbonizing, saving much fuel during the whole process, and increasing the enterprise revenue. And there is little smoking and pollution during the producing.

4. Raw material before and after carbonizing from our wood briquettes carbonization furnace:

Wood log, tree, tree branch, wood briquette, coconut shell, palm nutshell, Walnut Shell, Macadamia nutshell, bamboo, and other nut shell or hard raw material

5. Other carbonization furnace to make charcoal:

1) Energy saving carbonziation furnace:

A: raw material: raw wood, wood chip, tree (tree branch) coconut shell, nut shell, And briquette

B: Working principle : hot air carbonization process technology, this furnace can put three Carbonization tanks one time, and there are three lighting-up tuber, when light the fire, the energy can heat the three tanks at the same time, and it will save 50% energy. And we can equip the other three set tanks for recycle, and it will save cooling times

C: advantage:

1. is our newest developed product with 3 patents

2. Greatly increases carbonization ratio (increased from about 88% to 99%)

3. Shortens the carbonization time and shows the features of easy operation, higher safety and efficiency, energy saving and environmental protection.

D: Main data:

| Model | capacity | Dimension | Weight |

| THL-4 | 1800kg/24hour | 3*1.3*2.2m | 4500kg |

2) Square carbonization furnace:

A. Raw materials: Wood chips, wood branches, raw wood and wood briquettes and so on

B. Working principle: Burning by anoxic conditions, then the wood carbonized into charcoal

C: Carbonizing speed: 1-3 ton/day ( 8-12 hours for carbonization, 8-12hours for natural cooling)

D: Material the Furnace: special high temperature resistant material and steel plate

E: Operation: one people can control 4-5 set, don’t need the auxiliary machinery

F: Energy Consumption: 20-50kg firewood or 15-30kg natural gas

G: It adopted Superheated Stream cooling system, thus can speed up the cooling process, improve the quality of charcoal, and shorten the charring period.

H: Usage: Cooking fuel, Industrial fuel, Automotive fuel, Purification and filtration, Art, Horticulture, Medicine, Smoking, Environmental implications

I: Main data:

| Carbonization furnace | Size, m | Volumes | Capacity | Power | Temperature in the stove |

| THL-1 | 2.2*1.8*2.2 | 3CBM | 0.8-1 t/day | 1.5kw | 420-480 degree |

| THL-2 | 2.4*1.8*2.2 | 5CBM | 1.5-2t/day | 1.5kw | 420-480 degree |

| THL-3 | 3*2.0*2.2 | 6CBM | 2-2.5t/day | 1.5kw | 420-480 degree |

3) Sawdust carbonization machine:

A: The sawdust carboniztaion machine is our patent product, until now, just our company can produce this machine. The machine can change the sawdust to the charcoal powder directly,

B: Main data:

|

power :7.22kw ( main machine: 5.5kw, fan 1.5kw+0.22kw)

capacity :150-180kg/h

Package dimension:4800*1800*3200mm

Net/Gross weight:11.2/11.5ton

temperature of inner stove:480-600 degree

Raw material requirement :sawdust, Size: 3-5mm, moisture:8-12%

energy consumption:35-40kg firewood per shift

Electricity consumption:7.22kw/h

motor style :5.5kw Moment speed regulating motor

Used for: Firecracker production, active carbon processing, certain soil improvements by scientific research unit.

Rotary speed :1450r/min

|