- Product Details

- {{item.text}}

Quick Details

-

Power:

-

30kw(accordingly)

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2500 KG

-

Machinery Capacity:

-

7BBL

-

Product Name:

-

7bbl commercial used brewery equipment

-

Heating method:

-

electric/steam/direct fire heating

-

Material:

-

SUS304/SUS316

-

Application:

-

Microbrewery/hotel/pub/home

-

Function:

-

beer brewing

-

Keywords:

-

mini brewery

-

Control system:

-

PLC/PID

-

Weld:

-

100% TIG Welding

-

Insulation:

-

Polyurethane/rockwool 80-100mm

-

Equipment Usage:

-

microbrewery/brewpub/bar

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MICET

-

Voltage:

-

380V/230V/400V/415V

-

Power:

-

30kw(accordingly)

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2500 KG

-

Machinery Capacity:

-

7BBL

-

Product Name:

-

7bbl commercial used brewery equipment

-

Heating method:

-

electric/steam/direct fire heating

-

Material:

-

SUS304/SUS316

-

Application:

-

Microbrewery/hotel/pub/home

-

Function:

-

beer brewing

-

Keywords:

-

mini brewery

-

Control system:

-

PLC/PID

-

Weld:

-

100% TIG Welding

-

Insulation:

-

Polyurethane/rockwool 80-100mm

-

Equipment Usage:

-

microbrewery/brewpub/bar

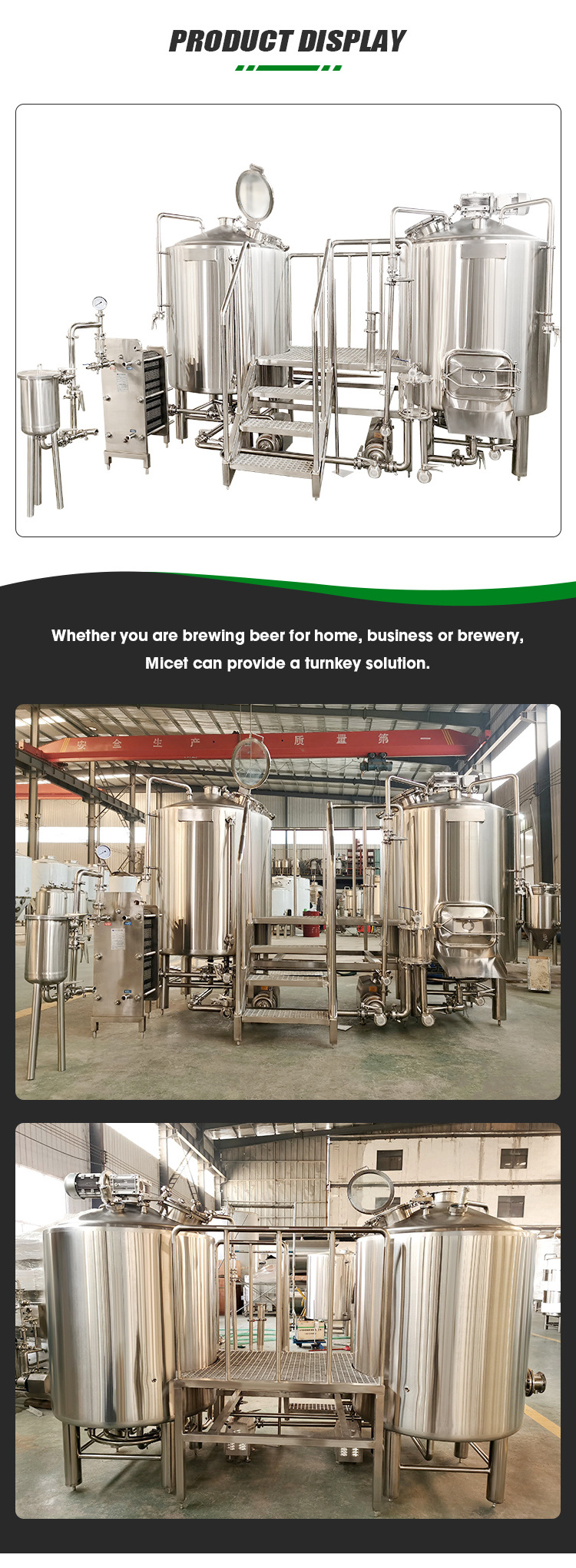

7BBL Commercial used beer brewing equipment stainless steel combined steam heated brewhouse industrial brewery

|

Output/ Brew

|

600L(5BBL)

|

800L(7BBL)

|

1000L

|

1500L

|

2000L

|

2500L

|

3000L

|

5000L

|

|||||||

|

Brew/Week

|

2~6

|

|

|

|

|

|

|

|

|||||||

|

Output/Week

|

12~36HL

|

16~48HL

|

20~60HL

|

30~90HL

|

40~120HL

|

150~300HL

|

180~360HL

|

240~360HL

|

|||||||

|

Area Request

|

>35㎡

|

>60㎡

|

>70㎡

|

>90㎡

|

>120㎡

|

>140㎡

|

>150㎡

|

>180㎡

|

|||||||

|

Brew master

|

1

|

1

|

1~2

|

1~2

|

2~3

|

2~3

|

3~5

|

3~5

|

|||||||

|

Material

|

Interior Shell: SUS304 TH=3mm; Exterior Shell:SUS304 TH=2mm /red copper

|

|

|

|

|

|

|

|

|||||||

|

Heating

|

Electric/Steam/Direct fire for optional

|

|

|

|

|

|

|

|

|||||||

|

Voltage

|

3 phase/380(220, 415,440...)v/50 (60)Hz

|

|

|

|

|

|

|

|

|||||||

1. Brewhouse manways always use full glass manway.

2. Mash tank is equipped with level gauge for easy observation

3.

0.7mm wedge-wire false bottom, can be disassembled to clean, bottom is supported and fixed.

4. Equipping with special inline hop filter to make the wort clearer before fermenting.

5. The pump/motor uses ABB or JLEM brand with CE/UL approved, long life and low sound.

6. Mash tun is equipped with grist hydrator to ensure uniform malt moistening.

7. Brewhouse piping design with cold and hot water mixing device and flow meter, which can evenly mix the cold and hot water before mashing.

8. The bottom of lauter tun is equipped with wort collection loop and an under-the-flush device.

9. Equipping with wort balance tank to check the clarity of wort and protect the sieve plate.

10. Equipping with sparge arm and double CIP cleaning loop on top of the tank.

11. To avoid too much water vapor, the kettle design with indoor exhaust or outdoor exhaust depending on customer needs.

12. Based on customer's brewing process, we can customize brewhouse to meet the feeding both in boiling kettle and lauter tun.

5. The pump/motor uses ABB or JLEM brand with CE/UL approved, long life and low sound.

6. Mash tun is equipped with grist hydrator to ensure uniform malt moistening.

7. Brewhouse piping design with cold and hot water mixing device and flow meter, which can evenly mix the cold and hot water before mashing.

8. The bottom of lauter tun is equipped with wort collection loop and an under-the-flush device.

9. Equipping with wort balance tank to check the clarity of wort and protect the sieve plate.

10. Equipping with sparge arm and double CIP cleaning loop on top of the tank.

11. To avoid too much water vapor, the kettle design with indoor exhaust or outdoor exhaust depending on customer needs.

12. Based on customer's brewing process, we can customize brewhouse to meet the feeding both in boiling kettle and lauter tun.

13.HLT design with return port, CIP and water inlet, which can realize the recovery and utilization of hot water between the heat exchanger.

14.The working platform adopts water leakage and a non-slip design.

1.What size of brewery we can provide?

We are manufacture of brewhouse in 2 vessel, 3 vessel and 4 vessel configurations and provide commercial brewery from 1HL to 100HL sizes for a wide range brewery needs.

2.Can you customize products according to customer requirements?

Yes, we support product customization.We are a factory, so you can tell our sales manager about the product requirements, and our engineers will design your own drawings for you.

3.

How long does it take to get the gear?

Normally our production lead time is 30-50 working days, depending on the order. Currently, we estimate 90-150 days for door-to-door delivery from the time we receive your deposit to delivery. Our delivery times will vary depending on the workload at the factory, but we do like to keep our delivery times honest so there are no surprises other than getting the equipment earlier than expected.

4.

How much space do I need to open a brewery?

This is not a question that can be answered very accurately, because every brewery has different requirements. If your brewery is too small, your space will be crowded. If your space is too large, you will waste a lot of money on startup costs and the space will not be well utilized. But we can provide you with some tips: 3BBL-5BBL brewery equipment needs about 300-500 square feet, and 7BBL-15BBL brewery equipment needs about 550-1200 square feet. Of course, if you need relatively accurate numbers, welcome to leave us a message.

5.What is your payment term?

1.T/T transfer, 40% advance payment for start production, after paying 60% balance payment for shipping.

2. Paypal or trade assurance is available.

6.

How to choose brewhouse equipment?

Brewhouse system selection for purchasing beer equipment there are about basically four types including 2 vessel brewhouse, 3 vessel brewhouse, and 4 vessel brewhouse. The combination type can be chosen depending on the client's budget, space size, local brewing process. We will also recommend according to old clients' experiences and different country brewing features.

Hot Searches