Germany

HOERBIGER

Hydraulic valve

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

100 mm

-

Dimension:

-

3000x2100x2450

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

RONGWIN

-

Year:

-

2022

-

Weight (KG):

-

5200

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

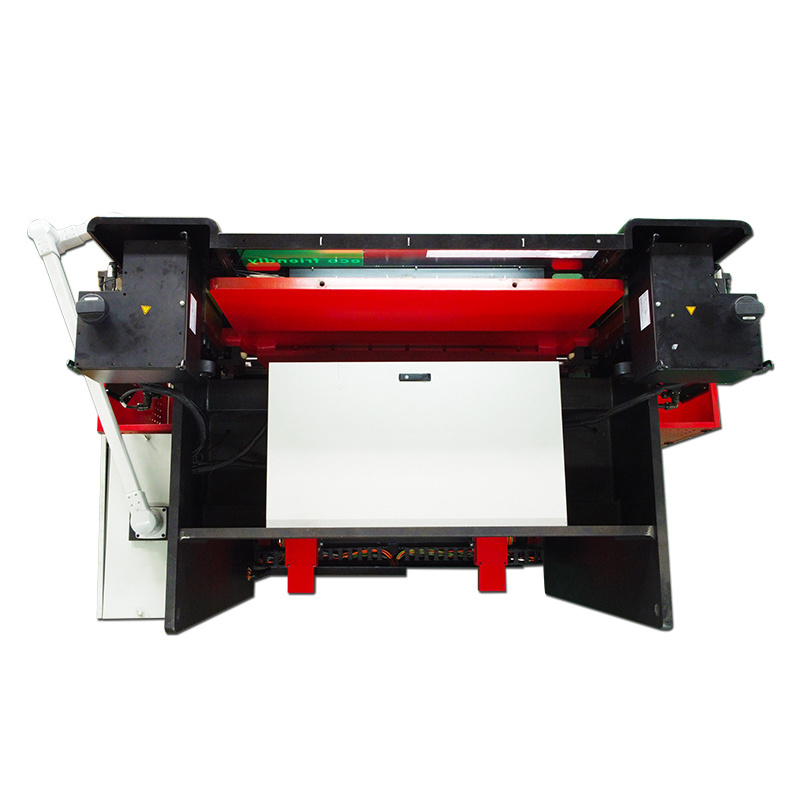

hybrid cnc sheet metal plate bending machine for sale

-

Nominal Pressure (kN):

-

800

-

Keyword:

-

hybrid press brake

-

Voltage:

-

220V/380V/415V/440V/customized

-

Control system:

-

DA69T-DA66T-DA58T-CT8-CT12

-

CNC Control Axis:

-

Y1-Y2-X1-X2-R1-R2-Z1-Z2

-

Company:

-

Nanjing RONGWIN Machinery Technology co.,ltd

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

2500

-

Slider Stroke (mm):

-

2500 mm

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

100 mm

-

Dimension:

-

3000x2100x2450

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

RONGWIN

-

Year:

-

2022

-

Weight (KG):

-

5200

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

hybrid cnc sheet metal plate bending machine for sale

-

Nominal Pressure (kN):

-

800

-

Keyword:

-

hybrid press brake

-

Voltage:

-

220V/380V/415V/440V/customized

-

Control system:

-

DA69T-DA66T-DA58T-CT8-CT12

-

CNC Control Axis:

-

Y1-Y2-X1-X2-R1-R2-Z1-Z2

-

Company:

-

Nanjing RONGWIN Machinery Technology co.,ltd

Products Description

Top level hybrid servo press brake from china cnc hydraulic press brake machine manufacturers price

WF67K -M Series Hydraulic Servo Combined CNC Press Brake

1. Dual-servo pumps control is a newly developed electro-hydraulic control scheme,which combines the advantages of two driving

technologies:strong hydraulic power and durability,compact design without external pipelines,and directly installed on the

cylinder,cleaner and leak-free.

1. Dual-servo pumps control is a newly developed electro-hydraulic control scheme,which combines the advantages of two driving

technologies:strong hydraulic power and durability,compact design without external pipelines,and directly installed on the

cylinder,cleaner and leak-free.

2. The system converts electrical signal transmission is carried out between CNC controller intomechanical linear motion.In order to accomplish this motion,signal transmission is carried out between CNC controller of machine

tool and motor drive controller.The synchronous cylinder controls the following work and fast running according to the preset working curve.A variable speed servo pump unit is used to drive and control the position of the bending tool and the bending force in the bending process.

tool and motor drive controller.The synchronous cylinder controls the following work and fast running according to the preset working curve.A variable speed servo pump unit is used to drive and control the position of the bending tool and the bending force in the bending process.

Our Advantages

Machine parameters

Detailed Images

Italy GIVI

Stable design Ball Scew Linear Guide

Electrical Type Crowing Table

High quality fast clamps

Easy to operate, time-saving and labor-saving

Avoid operator and third party hazards

(optional)

(optional)

Controlled by the control system, efficient and convenient (optional)

Optional Controller and Axis

A variety of control systems are available for you to choose. Different systems control different number of backguage axis. Customers can choose suitable solutions according to their own needs.

|

Quantity(Sets)

|

1-5

|

>5

|

|

Est. Time(days)

|

30

|

Negotiable

|

Hot Searches