- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ocean lucky

-

Voltage:

-

220v380v

-

Dimension(L*W*H):

-

700*195*80mm

-

Weight (KG):

-

52 KG

-

Power (kW):

-

1.5

-

Product Name:

-

Wood Planer Machine

-

Function:

-

Planing Wood Surface Smooth

-

Keywords:

-

Woodworking Thicknesser Machine

-

Application:

-

Woodworking Production

-

After-sales Service Provided:

-

Engineers

-

Feeding speed:

-

6m/min

-

Max working width:

-

630mm

-

Machine type:

-

Auotmatic

-

Advantage:

-

High Effeciency

-

Working Thickness:

-

3-180mm

Quick Details

-

Max.Planing Depth(mm):

-

0.8 mm

-

Max.Planing Width(mm):

-

150

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ocean lucky

-

Voltage:

-

220v380v

-

Dimension(L*W*H):

-

700*195*80mm

-

Weight (KG):

-

52 KG

-

Power (kW):

-

1.5

-

Product Name:

-

Wood Planer Machine

-

Function:

-

Planing Wood Surface Smooth

-

Keywords:

-

Woodworking Thicknesser Machine

-

Application:

-

Woodworking Production

-

After-sales Service Provided:

-

Engineers

-

Feeding speed:

-

6m/min

-

Max working width:

-

630mm

-

Machine type:

-

Auotmatic

-

Advantage:

-

High Effeciency

-

Working Thickness:

-

3-180mm

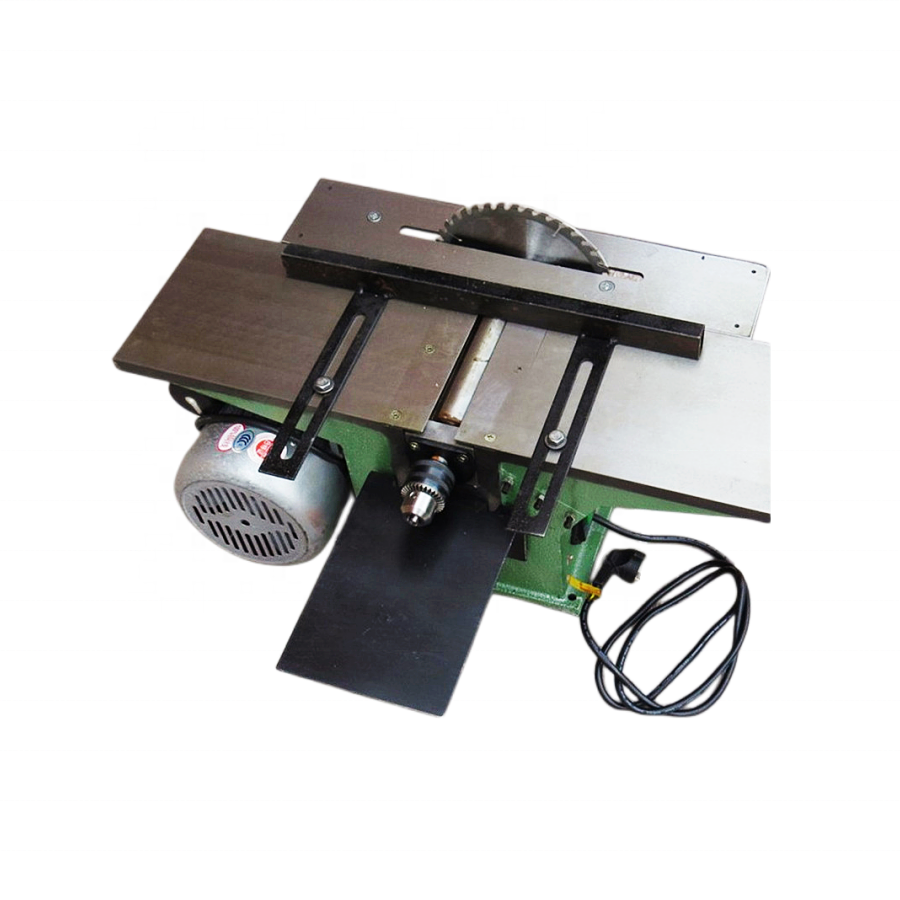

| model | ZY-B150 |

| Planing width | 150mm |

| Wood thickness | 90mm |

| Range of saw blades that can be installed | ≤235mm |

| Workbench size | 700mm*195mm |

| Spindle speed | 2800r⁄min |

| Motor power | 1.5kw |

| Overall weight | 52kg |

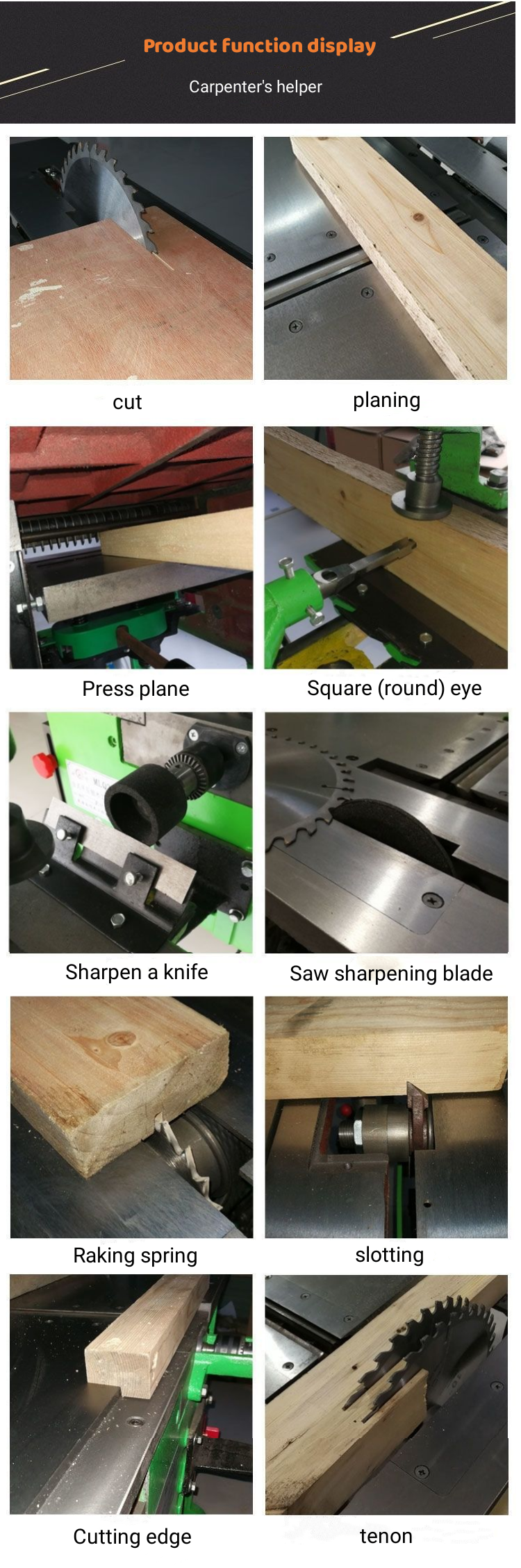

Adjustment, operation and maintenance of the planer

1. Before starting the machine, check whether the power supply voltage meets the requirements, and remove all items from the machine tool. First, press the switch, test run, observe the steering, and everything is normal before it can work.

2.During the sawing operation, the height of the saw table can be adjusted as needed, and the material should be fed smoothly.

3. When adjusting the blade, remember to cut off the power supply, then adjust the cutting blade to the same circle and parallel to the workbench. Tighten the compression nut handle to ensure that the blade is reliably tightened, and do not operate until there are no abnormal situations.

4. During planing, cutting, and shuttle reversing operations, the guide plate should be properly adjusted, and the cutting amount should be achieved through the lifting workbench, while avoiding approaching the planing mouth.

5. Clean the spindle and motor bearings every six months and add sufficient lubricating grease. Other relative moving parts should be lubricated frequently.

6. Long term storage of machine tools should be coated with anti rust oil. It is strictly prohibited to store heavy items on the workbench to prevent deformation, contact with corrosive gases, and unauthorized modification of electrical parts.

7. Before leaving the factory, all protective devices have been tested and can only be removed when one of the functions needs to be used. After use, install them to prevent injury.