- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ 3phase

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

3000 kg

-

Marketing Type:

-

fish feed making machine 2023

-

Machine name:

-

Aquatic Feed Fish Food Extruder Making Machine

-

Raw material of fish feed:

-

corn flour, fish meal, bone powder and so on

-

diameter of fish feed:

-

1-18mm

-

capacity:

-

2T/h 1500kg/h 1T/h 1000kg per hour 500kg/h 250kg/h 150kg/h

-

Usage:

-

Floating Sinking Aquatic Fish Feed making

-

material of machine:

-

stainless steel

-

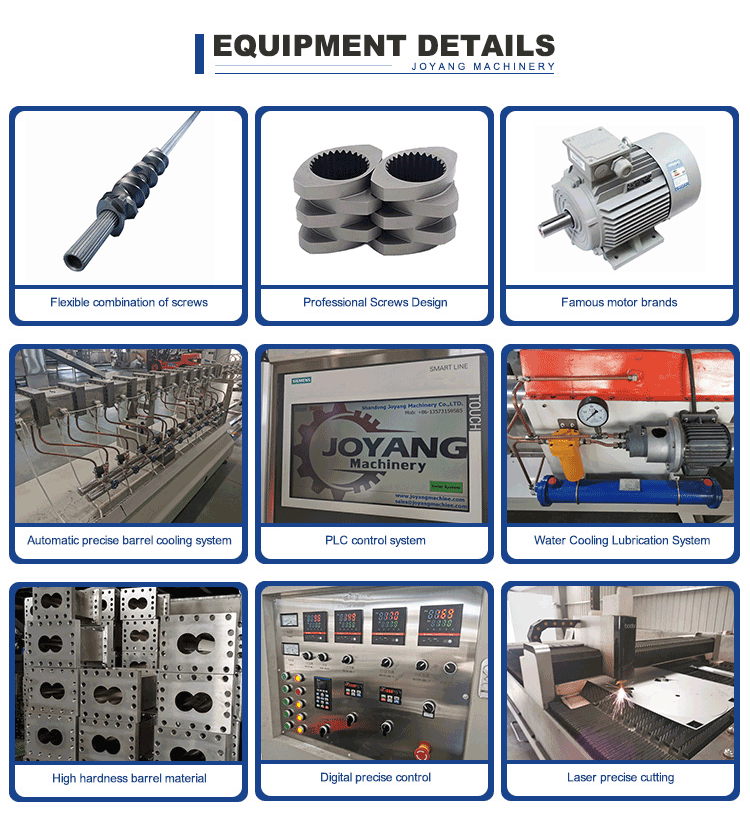

Main Machine:

-

Twin Screw Extruder

-

Motor:

-

SIMENS, ABB, Chinese famous brands

-

Certification:

-

CE

-

export country:

-

America, Europe, Mexico, Russia and so on

Quick Details

-

Max. Capacity:

-

2 ton/h 1ton/h 500kg/h 250 kg/h 150 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JY

-

Voltage:

-

380V 50HZ 3phase

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

3000 kg

-

Marketing Type:

-

fish feed making machine 2023

-

Machine name:

-

Aquatic Feed Fish Food Extruder Making Machine

-

Raw material of fish feed:

-

corn flour, fish meal, bone powder and so on

-

diameter of fish feed:

-

1-18mm

-

capacity:

-

2T/h 1500kg/h 1T/h 1000kg per hour 500kg/h 250kg/h 150kg/h

-

Usage:

-

Floating Sinking Aquatic Fish Feed making

-

material of machine:

-

stainless steel

-

Main Machine:

-

Twin Screw Extruder

-

Motor:

-

SIMENS, ABB, Chinese famous brands

-

Certification:

-

CE

-

export country:

-

America, Europe, Mexico, Russia and so on

Products Description

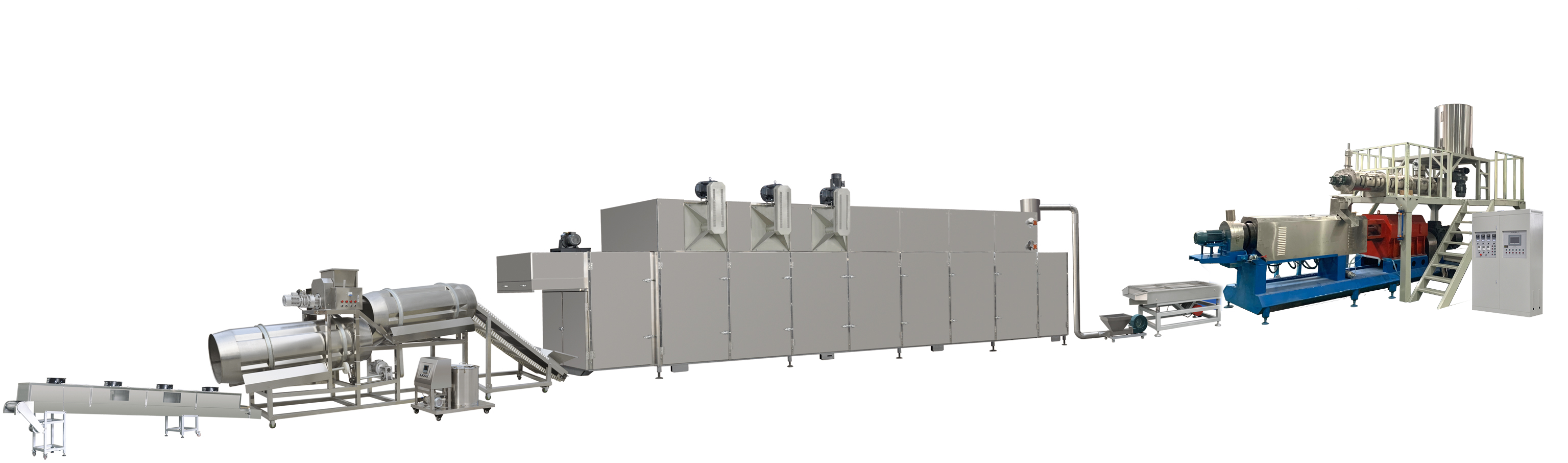

Floating Sinking Aquatic Feed Fish Food Extruder Making Machine

can use meat meal, fish meal, corn powder, soya meal and other grains powder as materials to make aquatic feed, such as floating fish feed, sinking fish feed, catfish feed, tilapia feed, tortoise food, turtle food,shrimp food,amd koi feed.

By changing the moulds and process technology, you can produce various shapes of pet food for cat, dog, fish, shrimp, bird and so on. The final feed is nutritional, multi-shape, attractive, highly digestible which can be loved by your pet and fish.

Product Paramenters

Dry extrusion lines:

|

Model

|

Install power

(kw)

|

Power consumption

(kw·h)

|

Capacity

(kg/h)

|

Dimension

(m)

|

|

JY-65

|

76

|

53

|

140-160

|

17×2.0×2.5

|

|

JY-70

|

105

|

75

|

240-260

|

22×2.0×2.5

|

|

JY-85

|

178

|

125

|

400-500

|

26×2.5×3.5

|

|

JY-90

|

215

|

165

|

800-1200

|

40×3.0×4.0

|

|

JY-95

|

256

|

195

|

1000--1500

|

42×3.0×4.0

|

Wet extrusion lines :

|

Model

|

Install power (kw)

|

steam consumption

(kg/h)

|

Capacity

(t/h)

|

Dimension

(m)

|

|

JY-0.4-0.6T

|

80

|

160-240

|

0.4-0.6

|

28×3.0×4.2

|

|

JY-0.8-1T

|

90

|

320-400

|

0.8-1

|

30×3.0×4.2

|

|

JY-1-1.5T

|

120

|

400-600

|

1-1.5

|

35×4.0×4.5

|

|

JY-1.5-2T

|

160

|

600-800

|

1.5-2

|

40×4.0×4.5

|

|

JY-2-3T

|

200

|

800-1200

|

2-3

|

45×5.0×5.5

|

|

JY-3-4T

|

270

|

1200-1600

|

3-4

|

48×6.0×6.5

|

|

JY-5-6T

|

390

|

2000-2400

|

5-6

|

52×6.5×8.0

|

Sample

Details Images

Customer Photos

Hot Searches