- Product Details

- {{item.text}}

Quick Details

-

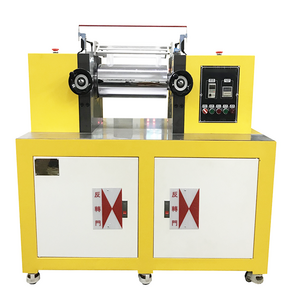

Roll Ratio(Front/Back):

-

1:1.25

-

Cooling Mode:

-

Water Cooling ( option)

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NewGoer

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

750*380*600mm

-

Power (kW):

-

2.2KW

-

Weight (KG):

-

128 KG

-

Roller Diameter:

-

100mm/3in

-

Mixed capacity:

-

300mm

-

Mixed Volume [Soft Gel]:

-

0.1~1kg

-

Roller temperature:

-

Normal temperature - 250°C(customisable)

-

Temperature uniformity:

-

2.5℃

-

Roller hardness:

-

50~60HRC

-

Roller handling:

-

Mirror polished chrome plated

-

Roller spacing:

-

0.1~6mm adjustable

-

Pitch display mode:

-

graduated scale

-

Safety device:

-

Crash Emergency Stop

Quick Details

-

Diameter of Roll(mm):

-

100 mm

-

Rotation Speed of Front Roll(rpm):

-

1 - 40 rpm

-

Length of Roll(mm):

-

350 mm

-

Roll Ratio(Front/Back):

-

1:1.25

-

Cooling Mode:

-

Water Cooling ( option)

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NewGoer

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

750*380*600mm

-

Power (kW):

-

2.2KW

-

Weight (KG):

-

128 KG

-

Roller Diameter:

-

100mm/3in

-

Mixed capacity:

-

300mm

-

Mixed Volume [Soft Gel]:

-

0.1~1kg

-

Roller temperature:

-

Normal temperature - 250°C(customisable)

-

Temperature uniformity:

-

2.5℃

-

Roller hardness:

-

50~60HRC

-

Roller handling:

-

Mirror polished chrome plated

-

Roller spacing:

-

0.1~6mm adjustable

-

Pitch display mode:

-

graduated scale

-

Safety device:

-

Crash Emergency Stop

Product Description

Equipment Overview:

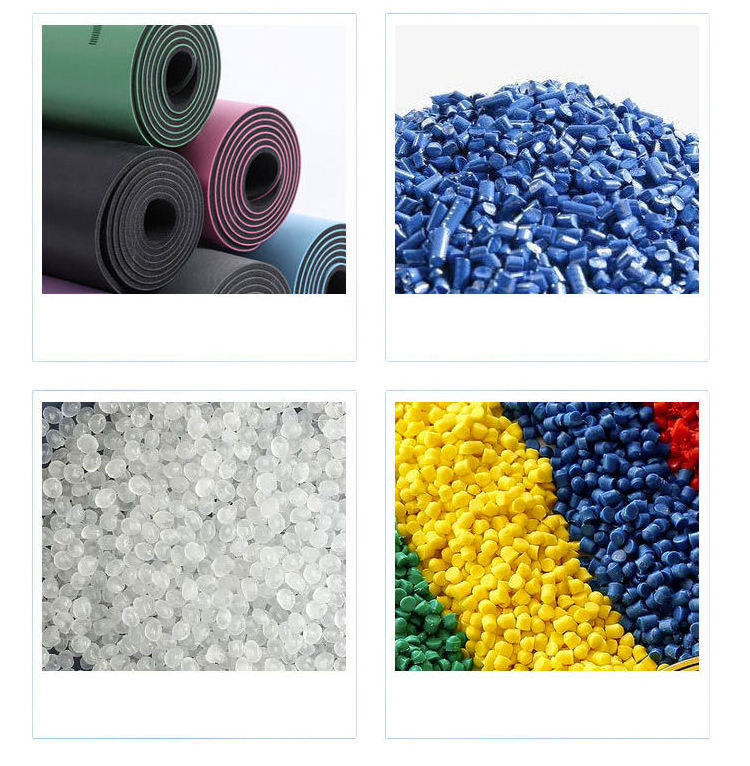

Rubber factory for the preparation of plastisol, mixing rubber or hot refining, out of a roller exposed rubber refining machinery. The main working parts are two different inwardly rotating hollow rollers or drilling rollers, the device on the operator's side is called the front rollers, can be manually or electrically acted horizontally forward and backward movement, in order to regulate the roller distance, to adapt to the operating requirements; the back rollers are fixed, can not be moved forward and backward. The two rollers are generally the same size, each with a different speed relative rotation, raw rubber or rubber with the rotation of the rollers are rolled into the gap between the two rollers, by the strong shear effect and achieve the purpose of plasticising or mixing. Openers are also used in plastics processing and other sectors.

Opening machine is the short name of open-type plastic refining machine, in the plastic products factory, people are accustomed to call it two-roller machine. The open kneader is a kind of mixing and refining plastic equipment which is applied earlier in the plastic products production factory. In the calender production line, the opening machine in the calender before, after the mixer, the role is to mix the raw materials for mixing, plasticising, calendering machine calendering plastic products to provide a mix of refining and moulding more uniform molten material. When producing cable material, the opener can directly refine and mould the powdered material mixed according to the formula into molten material, and then press and mould it into flake tape, so that the granulator can cut it into granule. In the production line of floor leather, it can directly provide the base coating for cloth-based leather with even mixing and plasticising. The recycled waste plastic film (sheet) can also be re-refined and moulded back to the system in the open refiner.

Specification

|

Roll Ratio(Front/Back)

|

1:1.25

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

2 years

|

|

Core Components

|

PLC, Engine

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

Brand Name

|

NewGoer

|

|

Dimension(L*W*H)

|

750*380*600mm

|

Precautions and Maintenance

4.1 Precautions:

4.1.1 The timer of this machine and the power supply of the motor are input according to the labelling.

4.1.2. The operator must be familiar with the operation and maintenance of the machine, and pay attention to the use.

4.1.3. Placement environment must be kept clean and free from moisture.

4.1.4 When necessary to move, please pay attention to the handling, do not damage the machine parts.

4.1.5 When replacing the fixtures, please pay attention to picking up and placing them so that they will not fall and hurt the machine parts.

4.1.6 Regularly inspect the drive belt for looseness and adjust it.

4.1.7 Please apply for inspection and calibration regularly to ensure the accuracy.

4.2 Maintenance matters:

4.2.1 Wipe the exterior of the machine frequently to keep it clean.

4.2.2 Wipe the electroplating part with machine oil to prevent rusting and keep it bright.

4.2.3 Add lubricating oil to the power screw and screw parts to keep the transmission sensitive. (Lubricating oil can be mixed with a little machine oil).

4.2.4 The panel (control box that is the display) please use a dry cloth to wipe, strictly prevent water, so as not to damage the IC electronic parts.

4.2.5 All jigs and fittings should be properly placed and wiped with anti-rust oil to prevent rust.

Packing & Delivery

Hot Searches