- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

hongfa

-

Voltage:

-

380V

-

Power:

-

17KW

-

Dimension(L*W*H):

-

3.5*2.25*1.2 m

-

Weight:

-

2000 kg

-

Features:

-

Easy Operation

Quick Details

-

Application:

-

wall panel

-

Production Capacity:

-

annual capacity 60,000 squ.m

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

hongfa

-

Voltage:

-

380V

-

Power:

-

17KW

-

Dimension(L*W*H):

-

3.5*2.25*1.2 m

-

Weight:

-

2000 kg

-

Features:

-

Easy Operation

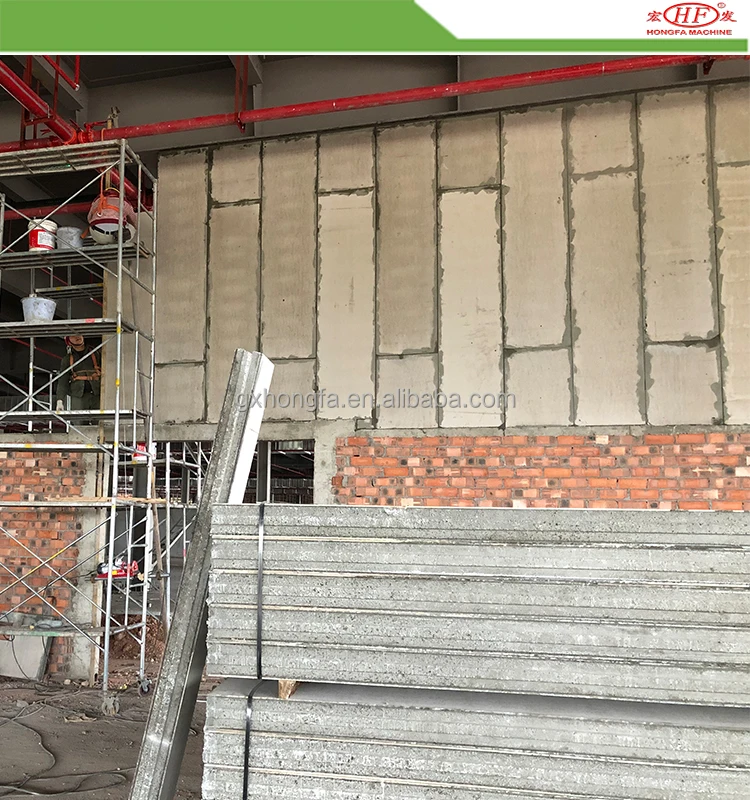

HONGFA Sandwich Panel Line Precast Concrete Wall Panel Machine Board Making Machinery HONGFA Sandwich Panel Line Precast Concrete Wall Panel Machine Calcium silicate board wall panel Making Machinery in Indonesia concrete fence mold Calcium silicate board wall panel Making Machinery in Philippine lightweight precast concrete panel machines lightweight precast concrete panel machine precast concrete hollow core wall panel machine precast concrete boundary wall making

Our Advantages

·High capacity.

·High speed materials filling.

·Low l abor intensity.

·Easy operation and maintenance.

· High- strength, high-density, and flat & smooth surface EPS panel.

·Flexible to produce all kinds of board

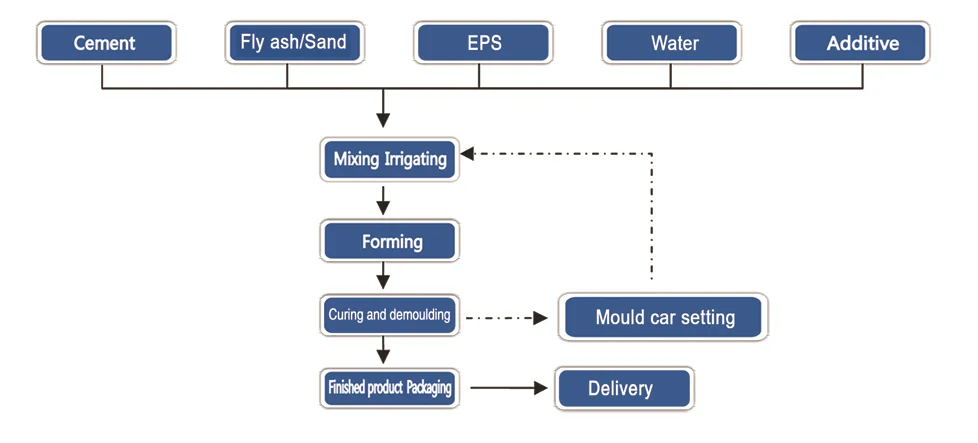

Process Flow and Material

Specification

Specification

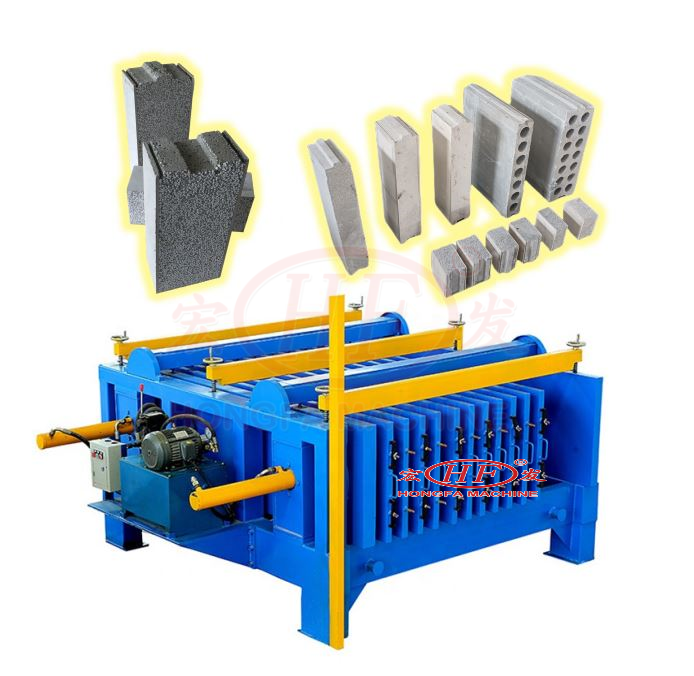

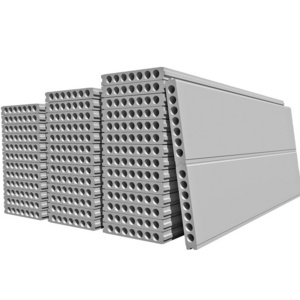

What kind of panels do you want to produce?

Our wall panel machine mainly produces the following types of panels

EPS concrete solid panel & hollow panel & gypsum panel & foam panel

It can be with or without calcium silicate board and fiber cement board.

EPS concrete solid panel & hollow panel & gypsum panel & foam panel

It can be with or without calcium silicate board and fiber cement board.

What We Can Do for Your Wall Panel Plant?

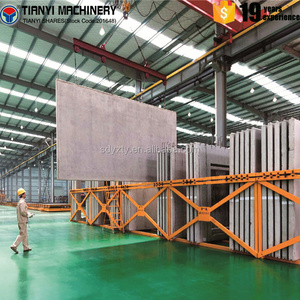

HONGFA manufactures 3 types production line, they are manual, semi and automatic style. Except for manufacturing machines, HONGFA is the only one company in China market which produce both panels and machines, with more than 8 years panel production experience, we will support you from machine setting to formula and panel installation on site.

Main Parts of Production Line

Main Parts of Production Line

HONGFA Sandwich Panel Line Precast Concrete Wall Panel Machine Board Making Machinery

1. Mixing plant

HONGFA mixing plant consists of mixer, movable infusion unit and aggregating system. It can mix all raw material automatically and

record every data for production. 3.6CBM capacity mixer guarantees infusion efficiency. It only needs about 15seconds to finish a

panel with size 2440*610*100mm.

record every data for production. 3.6CBM capacity mixer guarantees infusion efficiency. It only needs about 15seconds to finish a

panel with size 2440*610*100mm.

2. Boiler & EPS Expander

Boiler and EPS expander is used for expanding raw polysterene, one-time expander can make EPS around 7-18kg/CBM, interval expander

can get proportion on 3.5-6kg/CBM.

can get proportion on 3.5-6kg/CBM.

|

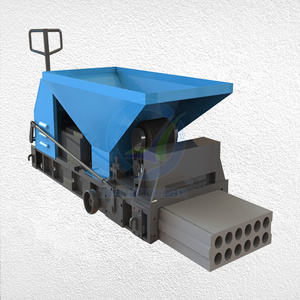

3. Molding machine

|

|||||

|

60MM

|

75MM

|

90MM

|

100MM

|

120MM

|

150MM

|

|

16pcs

|

14pcs

|

12pcs

|

12pcs

|

10pcs

|

8pcs

|

|

Dimensions(mm)

|

2750*2504*1359

|

||||

|

Power(KW)

|

3

|

||||

4. De-molding machine

De-molding machine can pull the cured panels out deirectly, Hongfa design it based on 6 years panel manufacturing experience, make

it possible that demolding machine is movable, after demolding, the molds can be installed immediately without any delay.

Multiwork is possible so efficiency is triple compared to traditional vertical manual and semi horizontal production line.

it possible that demolding machine is movable, after demolding, the molds can be installed immediately without any delay.

Multiwork is possible so efficiency is triple compared to traditional vertical manual and semi horizontal production line.

5. Recycling unit

Recycling unit can save eveything in production, waste slurry settling in underground mixer, the cement and sand will be pumped into mixer again for next mixing cycle. Keep production clean and make waste recycling, cost saving.

6. Hollow core panels unit

If you want hollow core wall panels with thickness above 150mm, HONGFA offers complete system solution. Hollow panels usually use for roof, cladding etc. purpose without any bearing demand.

7. Movable slurry piston pump unit

This unit uses for movable hydraulic slurry infusion, after mixing all raw material in mixer, then slurry pours into this movable

container, it can mix and inject at same time, guarantee slurry not falling down or the heavier material(sand or cement) separates

from lighter(EPS) one.

container, it can mix and inject at same time, guarantee slurry not falling down or the heavier material(sand or cement) separates

from lighter(EPS) one.

Certifications

Certifications

HONGFA Sandwich Panel Line Precast Concrete Wall Panel Machine Board Making Machinery

Packing and Shipping

Packing and Shipping

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer of board making machinery

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer of board making machinery

Company Introduction

Company Introduction

Hongfa Heavy Machinery Since 1990

1) More than 34 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M² and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

2) Total 4 factories with 440,000M² and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Hongfa Machinery's Honor

·One of Top Ten Influential Brands in China Brick &Tile Industry

·China National Enterprise Abiding By Contract & Keeping Good Faith

·Quality and Credibility of the Dual-protection Demonstration Unit

·High and New Technology Enterprise

·Famous Trademark of China

·Star Enterprise with China Patent

·AAA Grade Credit Enterprise

·Consumer Satisfaction Unit

·One of Top 100 building Material Industry Brands of China

·One of Top Ten Good Faith Units

·Advanced Exporter in Guangxi Province

·Advance Quality Management Unit

·One of Top Ten Influential Brands in China Brick &Tile Industry

·China National Enterprise Abiding By Contract & Keeping Good Faith

·Quality and Credibility of the Dual-protection Demonstration Unit

·High and New Technology Enterprise

·Famous Trademark of China

·Star Enterprise with China Patent

·AAA Grade Credit Enterprise

·Consumer Satisfaction Unit

·One of Top 100 building Material Industry Brands of China

·One of Top Ten Good Faith Units

·Advanced Exporter in Guangxi Province

·Advance Quality Management Unit

Our Services & Strength

Pre-sales service

We can design molding machine and aluminium mold according to your ideas before you make final decision, we are glad to add value to help you find best way make your ideal panels.

After-sales service

5 years after sales guarantee, 1 set of free spare parts available, free installation, free labor training, free formula testing

and lifespan technical maintenance guidance.

Pre-sales service

We can design molding machine and aluminium mold according to your ideas before you make final decision, we are glad to add value to help you find best way make your ideal panels.

After-sales service

5 years after sales guarantee, 1 set of free spare parts available, free installation, free labor training, free formula testing

and lifespan technical maintenance guidance.

Warm welcome to visit our factory!

FQA

FQA

Sandwich Panel Line Precast Concrete Wall Panel Machine Board Making Machinery

Q: What is the MOQ?

A: 5 sets.

Q: Can I mix different designs?

A: Sure!

Q: Can I get a lower price if I order large quantities?

A: Yes, cheaper prices with more bigger size orders.

Q: Can I add or delete items from my order if I change my mind?

A: Yes, but you need to tell us asap. If your order has been done in our production line, we cannot change

Q: When you ship my order?

A: Normally 30-45days after receiving your payment, but it can be negotiated based on order qty and production schedule.

Q: How about the quality guarantee period?

A: 1 year after shipment arrives.

Q: How can you guarantee the production quality?

A: Our production quality follow China construction machinery standard JGJ33-2012. We have 34 years experience on producing the machines and will be inspected by QC team for ach shipment. We have strictly quality control system in our production process. We have 4 times inspection for each finished product before package Third part inspection accepxable.

A: 5 sets.

Q: Can I mix different designs?

A: Sure!

Q: Can I get a lower price if I order large quantities?

A: Yes, cheaper prices with more bigger size orders.

Q: Can I add or delete items from my order if I change my mind?

A: Yes, but you need to tell us asap. If your order has been done in our production line, we cannot change

Q: When you ship my order?

A: Normally 30-45days after receiving your payment, but it can be negotiated based on order qty and production schedule.

Q: How about the quality guarantee period?

A: 1 year after shipment arrives.

Q: How can you guarantee the production quality?

A: Our production quality follow China construction machinery standard JGJ33-2012. We have 34 years experience on producing the machines and will be inspected by QC team for ach shipment. We have strictly quality control system in our production process. We have 4 times inspection for each finished product before package Third part inspection accepxable.

Hot Searches