A full range of pre-and after-sale technical support services to help customers improve product value. Continued after-sales service will lift the customer's worries in using our toolings. For each of our tools and blades, we will provide one year warranty!

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TR01011301

-

Material:

-

HSS

-

Design software:

-

PROE

-

Name:

-

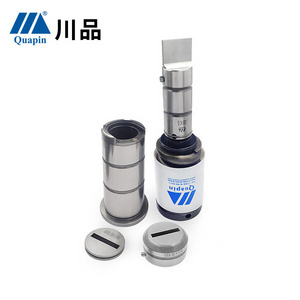

amada thick turret punch tool

-

Mould life:

-

700000-800000shots

-

Type:

-

punching

-

Cavity:

-

Single

-

Runner:

-

Cold Runner

-

Certification:

-

ISO9001:2000

-

Application:

-

Household Product Mold

-

Surface treatment:

-

Polishing

Quick Details

-

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Tenroy

-

Model Number:

-

TR01011301

-

Material:

-

HSS

-

Design software:

-

PROE

-

Name:

-

amada thick turret punch tool

-

Mould life:

-

700000-800000shots

-

Type:

-

punching

-

Cavity:

-

Single

-

Runner:

-

Cold Runner

-

Certification:

-

ISO9001:2000

-

Application:

-

Household Product Mold

-

Surface treatment:

-

Polishing

1. High speed tool steel;

2. Easy length adjustment-without a shim or replacement of mold;

3. Guide groove design, convenient for lubrication;

4. Slug free die design.

Tenroy standard thick turret toolings are suitable for Amada, Finn-power, Tailift, LFK, Yawei and other brand punch presses. It is the most practical types of sheet metal mold. It can improve the performance of tool, enhance flexibility and prolong the tooling life.

The related size of the thick turret punch press tools and the CNC punch press must be in accord with below table showing:

The basic parameters of each station for standard thick turret tools please see below table:

General Information:

|

Product Name

|

amada thick turret punch tool

|

|

Material

|

SKH51 for punch; SKD11 for die

|

|

Heat Treatment

|

HRC 61°- 63°

|

|

Hits before regrinding for stainless steel

|

About 30000 hits

|

|

Hits before regrinding for mild steel

|

About 50000 hits

|

|

Tooling Life for round

|

About 800000 hits

|

|

Tooling Life for shape

|

About 600000 – 700000 hits

|

|

Delivery Time

|

3-5 working days

|

Professional R & D Team

Tenroy has its own R & D team formed with 5 professional technicians, providing customers with mould design and selection, mould usage problem solution, mould maintenance and repair knowledge.

Quality Assurance

We adopt imported high quality tool steel. Each of our tools and blade will be tested before shipment. And their stable quality with long working life will be your best choice.

Lightning Delivery

Mass production of standard parts, smart stock! The lead time for standard type is 3-5 working days. And for special shape tools and blades, lead time is around 10-15 working days.

Packing Details: pack with carton box, 1set/small box, many sets/big strong carton box or wooden case.

Delivery Details: 3-5 working days

1. Anti rust oil before packing

2. Suitable carton size

3. Shock bubble film

4. Professional placement

5. Professional shock

6. Complete package

Full Range

A various types of tools and blades are available in our company. From punch press tools, bending tools to shearing blades and industrial cutters; from world famous brands of Amada, Strippit, Trumpf, Murata, Finn-Power, Nisshinbo etc. to China JFY, Yangli, Yawei, Jinan Jieda etc; from communications equipment, kitchen equipment, hotel equipment, solar energy equipment, power and electrical control cabinets, to aviation, military, ships, locomotives, cars, refrigerators, air conditioners, stoves, elevators, security door manufacturing, stainless steel decoration, cabinet manufacturing, and other sheet metal industries; we provide a full range of design and manufacturing for all the tools and blades that refer to above types, brand and application.

Service-Oriented

Price Advantage

Standardized and mass production! Factory direct sales with reasonable prices! Customize toolings with professional design will be more in line with customer's product, cost-effect and save your money and time.

Best Material

For press brake tools adopt 42CrMo and advanced processing technology. For punch press tools, we produce it with SKH-51 which can make the tools more durable and wear-resistant. For shearing blades & various industrial cutters, they are made from a special analysis of high carbon, high chrome tool steel.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the tools are standard. or it is 15-20 days if the tools is special forming shape.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: