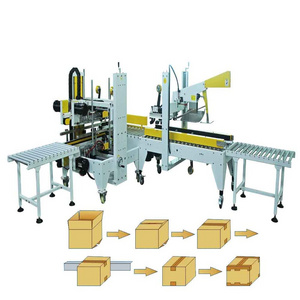

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

IVEN

-

Voltage:

-

380V / 50HZ

-

Power:

-

4000

-

Dimension(L*W*H):

-

5260*1830*2000 mm

-

Weight:

-

1600 kg

-

Product Name:

-

Box Folding Machine

-

Keyword:

-

Carton Box Making Machine

-

Production speed:

-

10-15 boxes/min

-

Table Height:

-

800 mm

-

Air Supply:

-

150L/min 6Mpa

-

Usage:

-

Box Packaging

-

Advantage:

-

High Capacity

-

Feature:

-

Stable Performance

-

Machine for:

-

Packaging

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Production Capacity:

-

200 pcs/min

-

Product Type:

-

Box Packaging

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

IVEN

-

Voltage:

-

380V / 50HZ

-

Power:

-

4000

-

Dimension(L*W*H):

-

5260*1830*2000 mm

-

Weight:

-

1600 kg

-

Product Name:

-

Box Folding Machine

-

Keyword:

-

Carton Box Making Machine

-

Production speed:

-

10-15 boxes/min

-

Table Height:

-

800 mm

-

Air Supply:

-

150L/min 6Mpa

-

Usage:

-

Box Packaging

-

Advantage:

-

High Capacity

-

Feature:

-

Stable Performance

-

Machine for:

-

Packaging

-

After Warranty Service:

-

Field maintenance and repair service

Automatic Cartoning Machine is suitable for packing blisters, tubes ampoules and other related objeces into boxes intermittently.It has advantage of high packing efficiency and good quality.

This machine can fold leafIet, open box, insert blister into box, emboss batch number and close box automatically. It adopts inverter to adjust speed, human machine interface to operate, PLC to control. and photoelectric to monitor and control each station automatically, so that once something unexpected happen,

it will stop and display the reasons automatically, which can solve the troubules in time. This machine can be used separately andalso can be linked together machine to be a Production line. Note: this machine canalso equip with hot meltgluedevice to do hot melt glus sealing for box.

Main Features:

1).Main drive: main motor located at the back of machine ,easy for maintenance. Synchronous belt drive instead of chain belt drive to reduce oil stain.

2).Guide rail installation method: guide rail of the cabinet is installed in cantilever way .It is convenient for the operator to remove the dropped medicine.

3).Mould base installation and adjustment: adopt lathe type guide rail and pinion and rack adjustment way. with position indicator and scale ruler for mould position adjustment.

4).All moulds including forming mould, heat-sealing mould, batch number emboss printing mould, punching mould

can be orientation-guide pushed into its position by hand and mould handle rocked to finish mould change fast with no need wrench or other tools.

5).Adopt air shaft to install PVC material and aluminum foil, adopt PVC connection device to change roll material more faster.

6).PVC loading adopt roller trace to avoid PVC material being over-stretched during material pulling

.

Application:

1).This machine is applied to Alu-Pvc and Alu-Alu packing of

medicines, for example sealed blister packing of capsules and

tablets of various specifications.

2).Applied to sealed blister packing of various syringes,

ampoule bottles and medical products.

3).Applied to sealed blister packing of food, electronic parts,

hardware products, etc.

Main Technical Parameters

| Model | ZHJ-80 | ZHJ-120 | ZHJ-150 |

| Production capacity | ≤80 boxes/min | ≤120 boxes/min | ≤150 boxes/min |

| Size of box(L×W×H) | (50-190)×(25-90)×(15-70)mm | (50-190)×(25-120)×(12-70)mm | (50-190)×(25-90)×(15-70)mm |

| Specification of box | 250-300g/m2 | 250-300g/m2 | 250-300g/m2 |

| Size of leaflet(L×W) | (110-260)×(100-180)mm | (110-260)×(100-180)mm | (110-260)×(100-180)mm |

| Specification of leaflet | 55-70g/m2 | 55-70g/m2 | 55-70g/m2 |

| Air consumption | 10m3/h | 10m3/h | 10m3/h |

| TotaI Power | 380V 50HZ 1.5kw | 380V 50HZ 1.5kw | 380V 50HZ 1.5kw |

| Overall Dimension(L×H×W) | 3300×1320×1700mm | 3300×1200×1700mm | 3300×1200×1700mm |

| Weight | 1200kg | 1500kg | 1500kg |

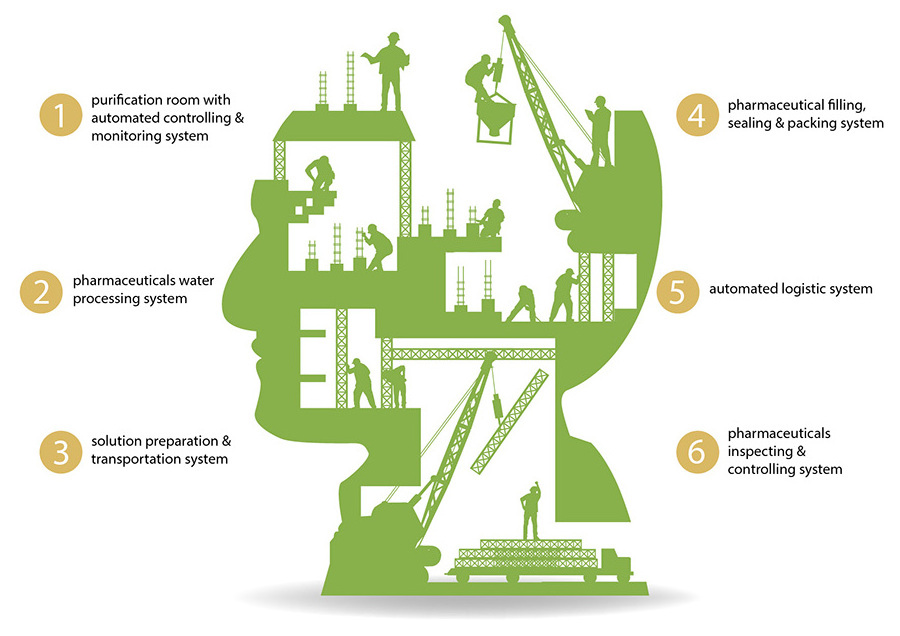

IVEN Can Do !

Turnkey Project for IV Solution Plant from A to Z

• Project Design

• Pharmaceutical Water Treatment

• Solution Preparation

• IV Solution Production Line

• Sterilization

• Inspections Packing

• Clean Room & HVAC

• Stability Chamber

• Laboratory Instruments

• Utilities

• Documentation & Qualification

• Installation, Commissioning, Training

• Service