- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

CNC automatic aluminum steel profile metal sheet bender

-

Type:

-

YN-VC on CNC automatic aluminum steel profile metal sheet bender

-

max stainless steel thickness:

-

1mm

-

max aluminum thickness:

-

1.2mm

-

max stainless steel width:

-

160mm

-

max aluminum:

-

160mm

-

suitable custmized:

-

CNC automatic aluminum steel profile metal sheet bender

-

Application:

-

aluminum and stainless steel

-

Keyword:

-

Bender

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

yunneng

-

Weight (KG):

-

320

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

CNC automatic aluminum steel profile metal sheet bender

-

Type:

-

YN-VC on CNC automatic aluminum steel profile metal sheet bender

-

max stainless steel thickness:

-

1mm

-

max aluminum thickness:

-

1.2mm

-

max stainless steel width:

-

160mm

-

max aluminum:

-

160mm

-

suitable custmized:

-

CNC automatic aluminum steel profile metal sheet bender

-

Application:

-

aluminum and stainless steel

-

Keyword:

-

Bender

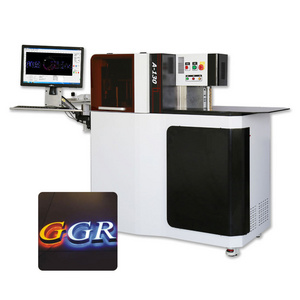

CNC automatic aluminum steel profile metal sheet bender

>>> Brief Introduction

Automatic CNC Bending Machine , (also called CNC letter bending machine or characterbending machine) is a new advertising production equipment,

which can be used for logos, signs, neon signs, billboards, light boxes production, outdoor advertising and other advertising production.

Aluminum+ Stainless Steel+Galvanized Iron = Three Functions in One

>>> Product Show

>>> Technical Data

|

Types |

YN-VC |

|

Operating principle |

Automatic feeding , notching and bending |

|

Available Material |

Aluminum , Stainless steel , Galvanized iron, Mild steel, Carbon steel |

|

Slot angle |

30°~130°( flat profile unlimited ) |

|

Bending Radius |

≥10mm |

|

Letter size |

≥10cm |

|

Max. processed width |

45-135mm ( option>135mm) |

|

Max. processed thickness |

Aluminum :0.3-1.2mm (option>1.5mm) Stainless steel:0.3-1.0mm Galvanized iron:0.3-1.0mm |

|

Driver motor |

Yako Stepper motor |

|

power |

≤1800W |

|

Feed speed |

10-40m/min |

|

Working format |

|

|

voltage |

220V |

|

Working air pressure |

0.6Mpa |

|

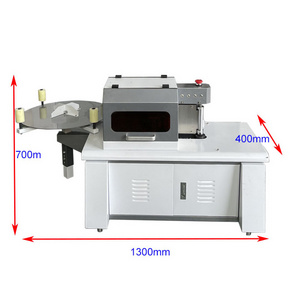

Machine size |

1850mm*880mm*1300mm |

|

Machine weight |

400KG |

>>> Samples Show

>>> Features

1. Aluminum/Stainless Steel profile Automatic straightening device

Before notching ,the profile will be compacted automatically, which will assure the smooth of the material and hi-precision cutting ;Automatic loose when no material or material feeding/return which make sure the

return material unobstructed.

2. Feeding system

Automatic feeding length measurement system BMO, control the feeding precision less than 0.05mm,improving the accuracy of the letter making.

3. Notching device:

Adopting the four slides location up and down motion and also use Japanese original gravity cylinder make the power transmission, the profile will be compacted automatically before notching,

which assure the stability and the precision of the slotting.

4. Bending device

Bending adopt up and down ,squeezing bending principle, use one squeeze roller to finish left and right bending,the advantage is when reverse bending, avoid transfer double roller bending lead to cambered surface rebound defect,this way the material will not deformation. We designed 200mm bending squeeze roller make the bending space amplification, it is more easy to bending small radian ,greatly improved the quality of letter making.

5.It can work in 0.05mmprecision , and work together with laser engraving machine , plasma cutting machine, CNC router to realize the advertisement processing .

6.Applicable material:flat aluminum coils, galvanized iron,mild steel,carbon steel,stainless steel.

>>> Advantages

1.New type of three-in-one CNC Channel letter bending machine, there are two working systems and different bending axes , one for stainless steel and iron, another for aluminum.

2.When we need to slot and bend different materials, Dot need to change the cutter. We just need to convert into another system.

3.And it is convenient for us to change the bending axis, just three to five minutes.

4.Therefore, this new machine can save time works with more efficiency .

5.We use Yako motor which is the best in its area.

6.The computer is original English PC.

>>> Application

1) Applicable Materials: Aluminum strip, stainless steel strip, iron , galvanized steel ect.

2) Applicable Industries: advertising industry, such as logos, signs, neon signs, billboards, light boxes production, outdoor advertising and other advertising production.

>>> Packaging

>>> Technical Characteristic

1.Cut angle from 45 to 130 and it can control depth precision,by using the CNC axis. the processing of various types of profile bending angle precision.

2.Intelligent control of the software,intelligent inspection to avoid collision in character bending process.

3.Telescopic bilaterally symmetrical bending mode of the unique,the greatest degree of bending process to avoid interference,and greatly improve the bending strength

4.Can read muti-vector file like the format such as AI,DXF matching with the engraving file perfectly.

5.Stainless steel gouging unique,single slotted mode profile milling groove,according to different characteristics of arbitrary switching material, the operation is simple and convenient .

6.Use rotary type handwheel to adjust the feed depth,the operation is simple and convenient.

Sign making procedure:

Click below,you will have a surprise!!!

Q: Are you a factory or a trade company?

A: We are a factory.

Q: How many years do you do this business?

A: From 2013.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in

Shandong

province, China.

All our clients from home or abroad are warmly welcome to visit us!

Q: Do you have any certificates?

A: All series of machines have passed CE,CO and ISO verification.

Q: What is the trade term?

A: FOB/CNF/CFR/CIF/EXW are favorable.

Q: What is the payment term?

A: T/T , West Union, L/C, D/P etc.

Q: How can I get the documents after shipment?

A: All original documents will be sent to the client by

UPS

.

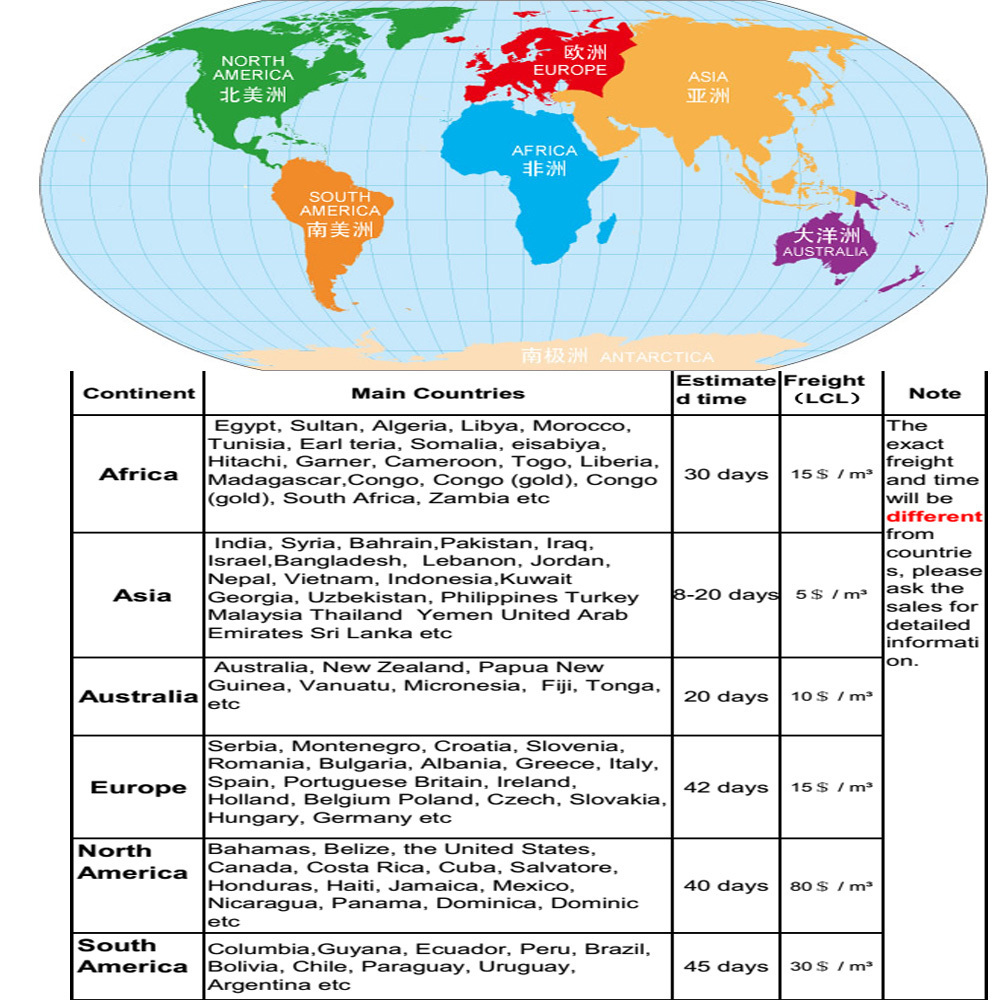

Q: Do you arrange shipment for the machines?

A: We will arrange shipment for transactions based on FOB/CIF terms.

For EXW price, shipment should be made by clients or their agents.

Q: Warranty?

A: Depend on the series of machine.

Q: Where have you sold your products?

A: Europe, Americas, Africa, Asia and so on.

Q: Do you have patents or core technology?

A: Yes, for details, please contact our sales.