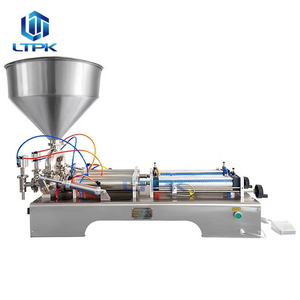

1、Touch screen type operation interface.

2、Up and down motion filling effectively prevent foam generation, easy to disassemble and clean filling

3、Filling accuracy can reach ±1%.

4、Filling cylinder by grinding treatment unique filling valve design, no dripping.

5、With the function of no bottle not filling and automatic stopping of accumulated bottles.

6、According to the actual situation of the bottle design of different positioning devices.

7、Equipment can be easily cleaned and disassembled without tools. It can also be cleaned online or autoclaved.

8、PLC programmable control adopts Japan Mitsubishi.

9、French Schneider is used for frequency converter

10、Pneumatic components adopt Taiwan ADATA.

11. SUS304# stainless steel is used for the material in contact with the equipment.

12、Equipment meets health and safety standards

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.5%

-

Voltage:

-

220V

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

KST

-

Dimension(L*W*H):

-

3000*1500*2100mm

-

Weight:

-

650 KG

-

Product name:

-

Tracking piston filling machine

-

Usage:

-

Filling Capping Labeling Packaging

-

Filling speed:

-

40-60bottles/min

-

Filling range:

-

500-5000ml

-

Power:

-

8.6kw,380v

-

Air pressure:

-

0.6-0.7mpa

-

Control:

-

PLC+ Touch Screen

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Machinery Capacity:

-

1440-1800BPH

-

Packaging Material:

-

Glass, Wood

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

99.5%

-

Voltage:

-

220V

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

KST

-

Dimension(L*W*H):

-

3000*1500*2100mm

-

Weight:

-

650 KG

-

Product name:

-

Tracking piston filling machine

-

Usage:

-

Filling Capping Labeling Packaging

-

Filling speed:

-

40-60bottles/min

-

Filling range:

-

500-5000ml

-

Power:

-

8.6kw,380v

-

Air pressure:

-

0.6-0.7mpa

-

Control:

-

PLC+ Touch Screen

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

KST-GCS-4

Tracking piston filling machine

|

Model

|

KST-GSF-4

|

|

Labeling accuracy

|

99.5%

|

|

Filling range

|

500~5000ml

|

|

Filling speed

|

40-60 bottles/min

|

|

Power

|

8.6kw、380v (can be customized)

|

|

Working air pressure

|

6~7kg/cm²

|

|

Air pressure

|

0.6-0.7mpa

|

|

Keyword

|

Tracking piston filling machine

|

|

Weight

|

650kg

|

KST grown from the brand of "Ming dian",was established in Chengdu,China in the year of 2011.It is an integrating enterprase of R&D, manufacturing and sales. With more than 10years experences in fieds of packaging solutions,KST be the leading supplier for industries as tea,coffee,food and medicine etc...

Since KST building, "Ming dian" dedicated in "MADE IN CHINA 2025" and product coverage reaches 30% at home and 70% abroad international market.Focus on the development and service of international market. KST creating a SAFE,STABLE and HIGH-PERFORMANCE packaging equipment system,providing our customers with exclusive services,keeping our goals as "Quality guarantee""Delivery guarantee""Consistent improvement""Customer satisfaction". We are willing to cooperate with all our clients and seek our common development.

CONTACT US

If you would like to know more product details and inspection reports, please contact us

FAQ

Service before Sale

1

.

24 hours on line

for quick response: reply within 2 hours for any inquiry.

2.

Free

solutions consultation.

3.

Free

sample testing.

4.

Visit our factory

is welcome.

Service on Sale

1. Strict QC for each assembling process, testing and assembled machines.

2.

Assembling pictures / testing videos

during production is available.

3. Pack well with

standard export wooden case

after you confirm the machine is OK for shipment:

Cleaning---Oil---Wrapping---Fixed tightly

in wooden case.

4. Delivery on time.

Service after Sale

1. Free training.

2.

Operation manual and videos

for installation, setting, debugging, maintenance

3.

Free online communication

with our

engineer

is available.

4. Quick

answers within 2 hours

for any questions.

5. AS engineer is available to send to your factory for services.

6. During warranty, if any defects or malfunctions which have been proved to be caused by our side, we are obliged to

supply technical assistance to the buyer

to ensure their normal production and

send spare parts for replace as free

, but the buyer should pay the transport charges.

Hot Searches