- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Naseiko

-

Voltage:

-

380V

-

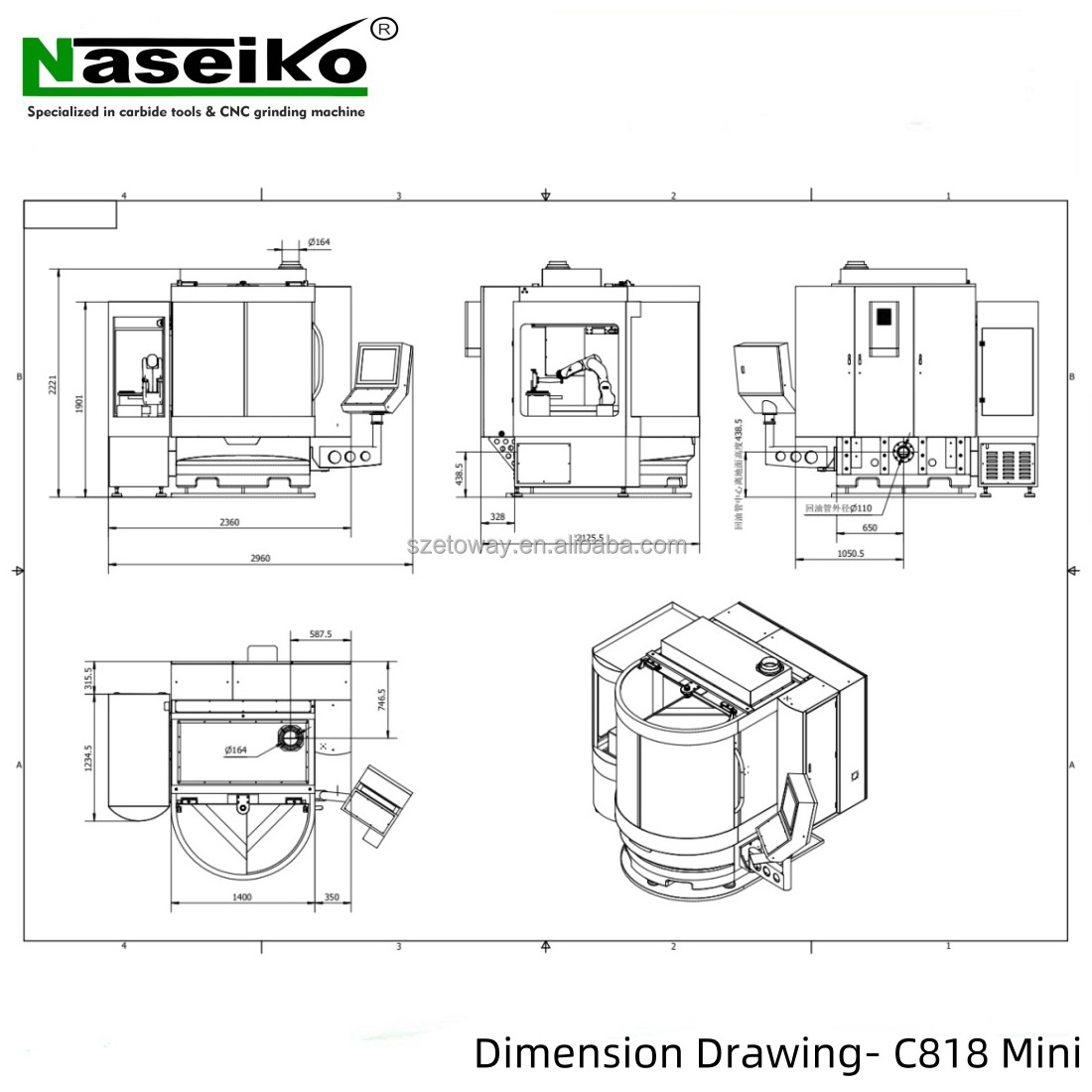

Dimension(L*W*H):

-

2960*2221*2360 (mm)

-

Weight (KG):

-

4000

-

Power (kW):

-

≤ 22.5

-

Product name:

-

5-Axis Tool Grinding Machine

-

Model:

-

C818 Mini

-

Brand:

-

Naseiko

-

Resolution:

-

0.0001mm

Quick Details

-

Wheel Size(mm):

-

75~150

-

Year:

-

2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Naseiko

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2960*2221*2360 (mm)

-

Weight (KG):

-

4000

-

Power (kW):

-

≤ 22.5

-

Product name:

-

5-Axis Tool Grinding Machine

-

Model:

-

C818 Mini

-

Brand:

-

Naseiko

-

Resolution:

-

0.0001mm

Product Overview

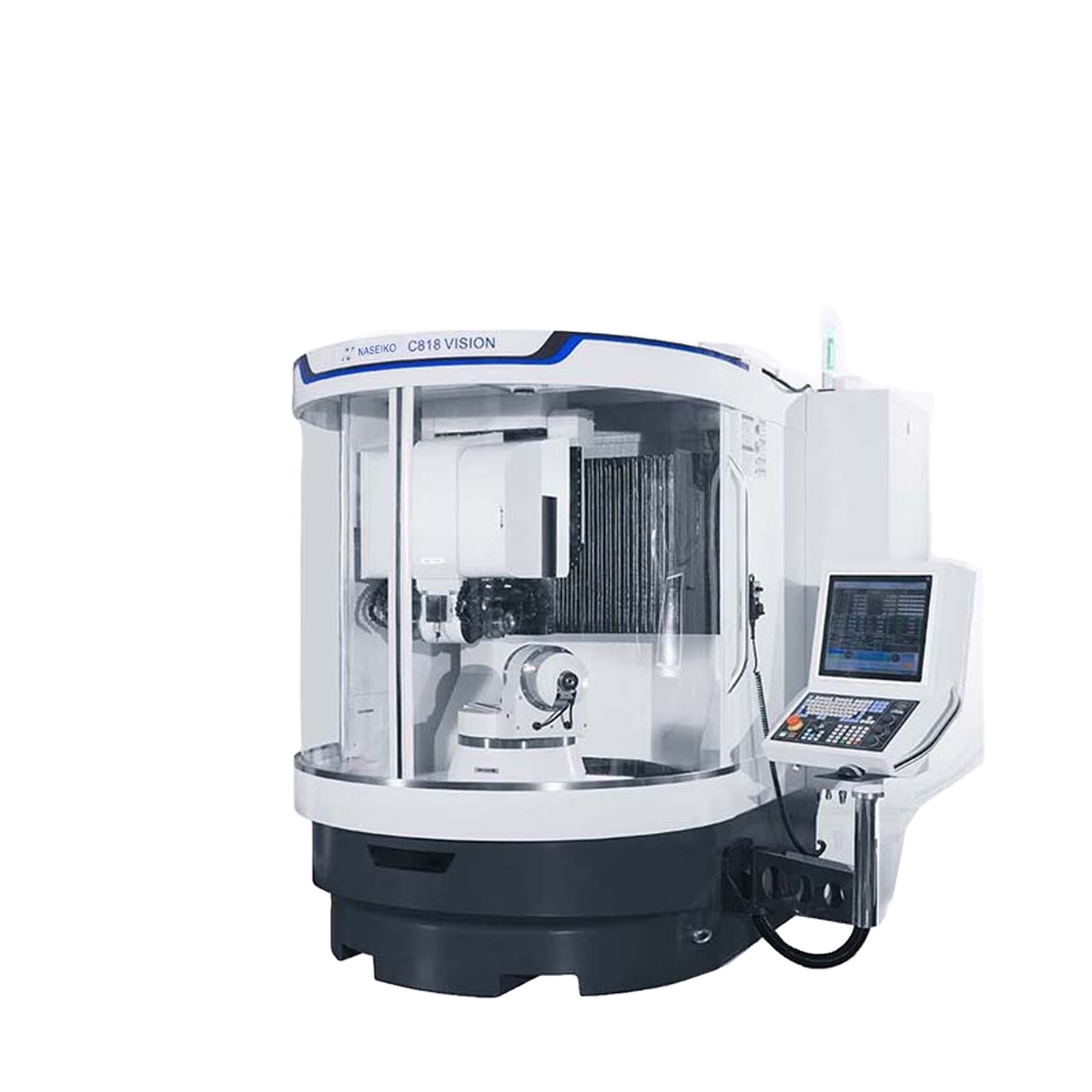

5-Axis Tool Grinding Machine Mini C818 CNC Grinder

The 5-axis 5-linkage CNC tool grinder is based on the experience of the German 5-axis CNC tool grinder .

It is designed based on the practical experience of designers and exchanges at the tool production site,in terms of practicality, economy, operation, maintenance, stability and efficiency be reflected.

The machine tool adopts an integral imported organic glass circular door to facilitate unrestricted operation and maintenance of the machine tool. The fully enclosed protective cover complies with production safety.

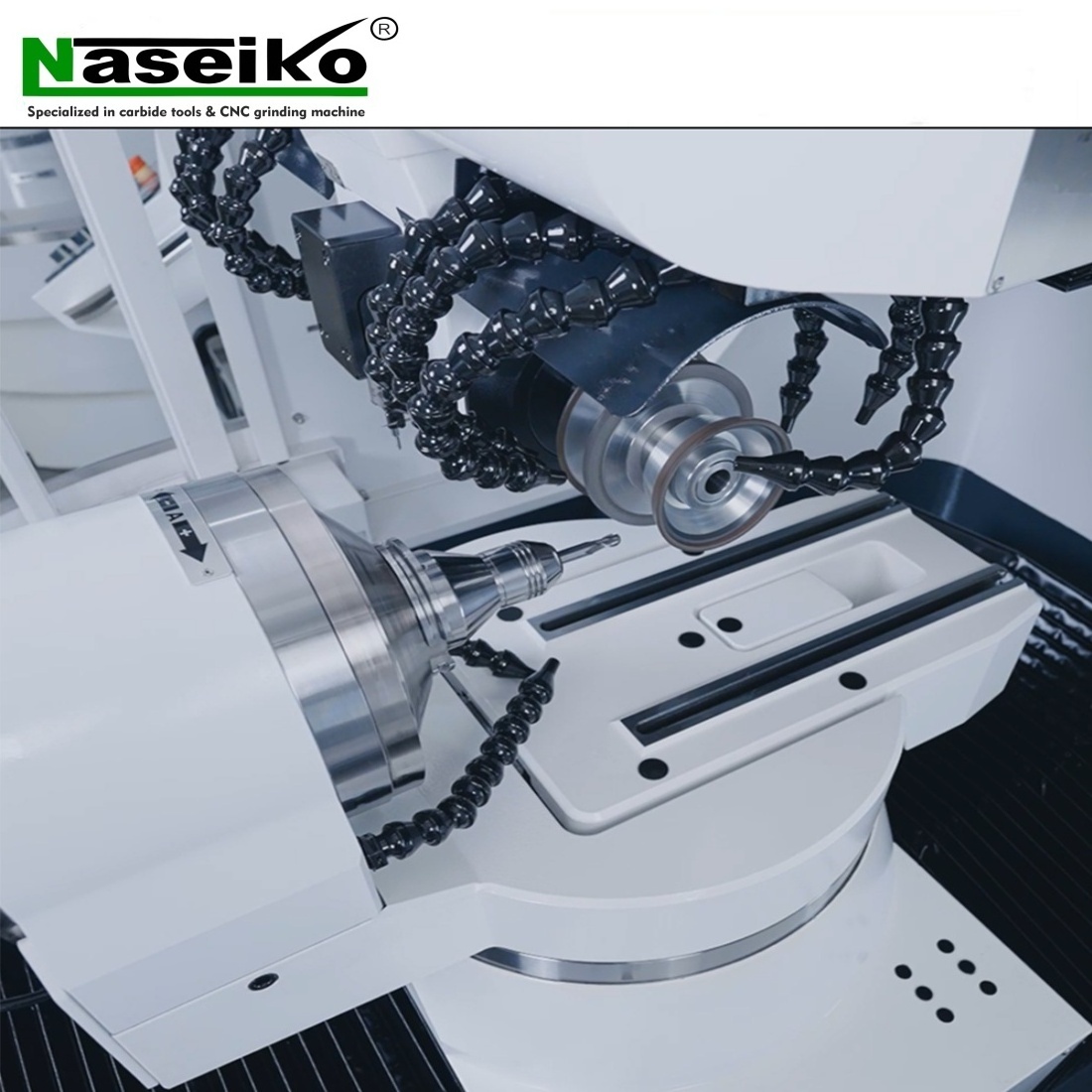

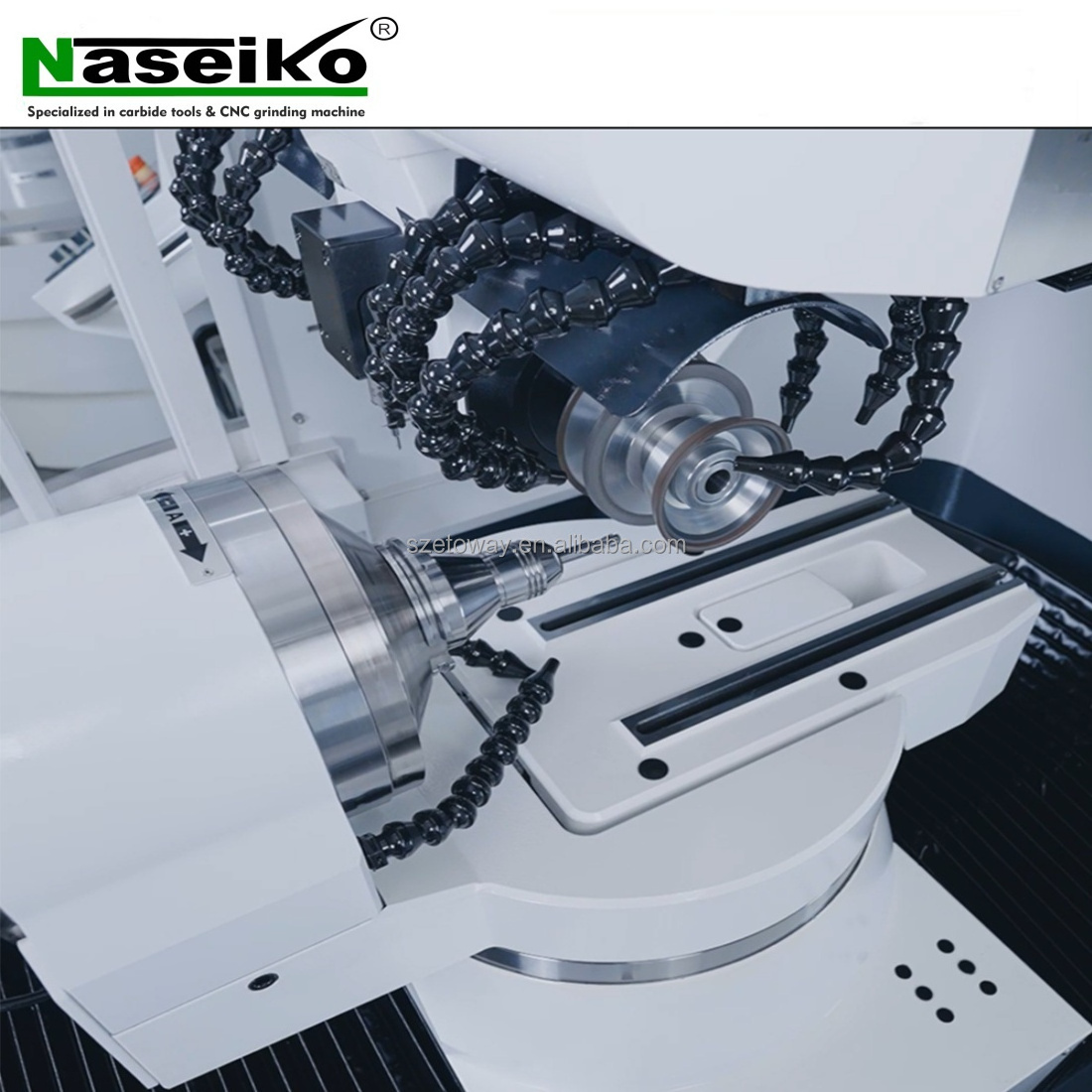

In order to cope with the production of special tools, the relative position relationship of the servo axis of the equipment is optimized, which can correspond to many types of tools processing machine structure.

All axes use imported servo motors and screw guides with high precision and resolution to ensure high production efficiency and quality of the cutting tools.

Product Paramenters

|

Item

|

Unit

|

C818 Mini

|

|

Japan servo motor drive (absolute value) stroke (X/Y/Z axis)

|

mm

|

650/350/270

|

|

CNC system resolution (X/Y/Z axis)

|

mm

|

0.0001

|

|

Minimum resolution for programming of handwheel feed (X/Y/Z axis)

|

mm

|

0.0001

|

|

THK screw (X/Y/Z axis)

|

-

|

BN-FN32-C3

|

|

Repositioning accuracy (X/Y/Z axis)

|

mm

|

0.003

|

|

Guide rail (X/Y/Z axis)

|

-

|

MR35- G1/MR35- G1/SRG35-P

|

|

Workpiece rotation axis (A/B axis)

|

-

|

rotation axis

|

|

DD servo drive (A/B axis)

|

-

|

direct drive

|

|

Rotary encoder (A/B axis)

|

-

|

RENISHAW, UK

|

|

Indexing accuracy (A/B axis)

|

-

|

2 arc seconds (0.0005 degrees)

|

|

Rated speed (A/B axis)

|

rpm

|

300/100

|

|

Maximum revolutions (A/B axis)

|

rpm

|

400/150

|

|

CNC system resolution (A/B axis)

|

degree

|

0.0001

|

|

360 degree rotation, indexing head body (A/B axis)

|

-

|

Could be installed with Shaw Berlin W25 collet holder or BT50 knife handle

|

|

Quick movement (X/Y/Z axis)

|

m/min

|

7.5

|

|

Minimum diameter for clamping workpiece

|

mm

|

3

|

|

Maximum diameter for clamping workpiece

|

mm

|

20

|

|

Maximum length for clamping workpiece

|

mm

|

200

|

|

Minimum diameter for grinding workpiece

|

mm

|

1

|

|

Maximum diameter for grinding workpiece

|

mm

|

12

|

|

Maximum blade length for grinding

|

mm

|

≤120

|

|

Maximum workpiece weight

|

kg

|

5

|

|

Linear resolution

|

mm

|

0.0001

|

|

Linear repeat positioning accuracy

|

mm

|

0.003

|

|

Rotation resolution

|

mm

|

0.0001

|

|

Rotation Repetitive Positioning Accuracy

|

degree

|

0.001

|

|

Spindle power

|

kw

|

12~15kw permanent magnet variable frequency motor

|

|

Grinding wheel diameter

|

mm

|

75-150

|

|

Grinding wheel spindle speed

|

rpm

|

4000-8000

|

|

Stepless adjustable

|

-

|

inverter

|

|

Machine weight

|

kg

|

4000

|

|

Total power

|

kw

|

≤22.5kw

|

Details Images

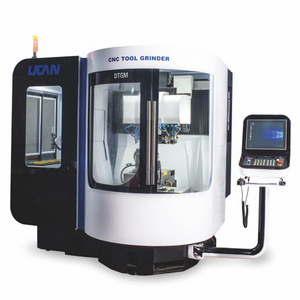

Recommend Products

FAQ

Q: What is your product line?

A:

CNC grinding machine,

CNC mismatch grinder machine,

Electronics servo press machine,

Precision Grinding Wheel Dressing Machine.

Carbide end mill, carbide burr, dental burrs, and other tungsten carbide items,etc.

Q: Is ODM or OEM production supported?

A: Yes.

Q: What is MOQ for your product?

A: For standard models machine , MOQ is 1 set ;

For OEM ODM customized machine , MOQ is from 10 sets .

For carbide tools , MOQ is from 1000 units .

Q: How long is the delivery time?

A: For standard Naseiko machine , it is about 1-2 months after order confirmed;

For customized machine , it will be 6~12 months after order confirmed;

For customized milling cutter or carbide burrs , it is about 1 month .

Q: Where is your loading port?

A: Shanghai / Guangzhou ,China port.

Q: How do you implement equipment warranty overseas?

A: At present, we have contracted after-sales service points overseas, and in the future, we will establish our own after-sales service centers in key overseas markets .

Q: What are your benefits superior to other suppliers?

A: Naseiko Intelligent technology is a manufacturing enterprise with years of industry experience, focusing on the research and production of CNC tool grinders. Our team has rich experience and professional knowledge in this field.

We have international advanced testing equipment, excellent craftsmanship and refine quality management system,

as well as professional team. It ensures our products stable and reliable.

CNC mismatch grinder machine,

Electronics servo press machine,

Precision Grinding Wheel Dressing Machine.

Carbide end mill, carbide burr, dental burrs, and other tungsten carbide items,etc.

Q: Is ODM or OEM production supported?

A: Yes.

Q: What is MOQ for your product?

A: For standard models machine , MOQ is 1 set ;

For OEM ODM customized machine , MOQ is from 10 sets .

For carbide tools , MOQ is from 1000 units .

Q: How long is the delivery time?

A: For standard Naseiko machine , it is about 1-2 months after order confirmed;

For customized machine , it will be 6~12 months after order confirmed;

For customized milling cutter or carbide burrs , it is about 1 month .

Q: Where is your loading port?

A: Shanghai / Guangzhou ,China port.

Q: How do you implement equipment warranty overseas?

A: At present, we have contracted after-sales service points overseas, and in the future, we will establish our own after-sales service centers in key overseas markets .

Q: What are your benefits superior to other suppliers?

A: Naseiko Intelligent technology is a manufacturing enterprise with years of industry experience, focusing on the research and production of CNC tool grinders. Our team has rich experience and professional knowledge in this field.

We have international advanced testing equipment, excellent craftsmanship and refine quality management system,

as well as professional team. It ensures our products stable and reliable.

Hot Searches