- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

/

-

Brand Name:

-

yisun

-

Material:

-

Plastice

-

Product name:

-

Custom 3d Printer Rapid Prototype Service

-

Process:

-

Polish

-

Color:

-

Customized Color

-

Service:

-

Cutomized

-

Surface treatment:

-

Customer's Request

-

Equipment:

-

3D Printer

-

Drawing Format:

-

IGS STP STL

-

Size:

-

Customized Sizes Acceptable

-

Tolerance:

-

0.1mm

Quick Details

-

CNC Machining or Not:

-

Not CNC Machining

-

Material Capabilities:

-

Aluminum, Stainless steel

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

/

-

Brand Name:

-

yisun

-

Material:

-

Plastice

-

Product name:

-

Custom 3d Printer Rapid Prototype Service

-

Process:

-

Polish

-

Color:

-

Customized Color

-

Service:

-

Cutomized

-

Surface treatment:

-

Customer's Request

-

Equipment:

-

3D Printer

-

Drawing Format:

-

IGS STP STL

-

Size:

-

Customized Sizes Acceptable

-

Tolerance:

-

0.1mm

Essential Details

|

CNC Machining or Not

|

Not CNC Machining

|

OEM:

|

Accepted

|

|

Micro Machining or Not

|

Micro Machining

|

MOQ

|

1 pcs

|

|

Brand Name

|

YIsun

|

Toranrance:

|

±0.1mm

|

|

Type:

|

Laser Machining, Other Machining Services, Rapid Prototying

|

Color

|

Can be customized

|

|

Material Capabilities:

|

Metal、Steel、Aluminum、Stainless steel、titanium

|

Files format

|

3dm&igs&stp&stl

|

|

Surface treatment

|

Polish、Spray paint、Deburring, Sandblasting、etc

|

Lead time

|

3-8days

|

Printing Process

Introduction to 3D Printing

3D rapid prototyping technology can save time and cost compared with traditional prototype making process..Its cost is about 20%~35% of the traditional processing method.

Print samples can be more accurates which means It is suitable for making models with complex structures.It makes your design ideas and product functions more vivid and intuitive.

It is easier for you to find and solve product problems, thereby further shortening the product design cycle and responding to the market faster.

3D rapid prototyping enables cost reduction,and it is more conducive to enhancing the core competitiveness of enterprises.

Print samples can be more accurates which means It is suitable for making models with complex structures.It makes your design ideas and product functions more vivid and intuitive.

It is easier for you to find and solve product problems, thereby further shortening the product design cycle and responding to the market faster.

3D rapid prototyping enables cost reduction,and it is more conducive to enhancing the core competitiveness of enterprises.

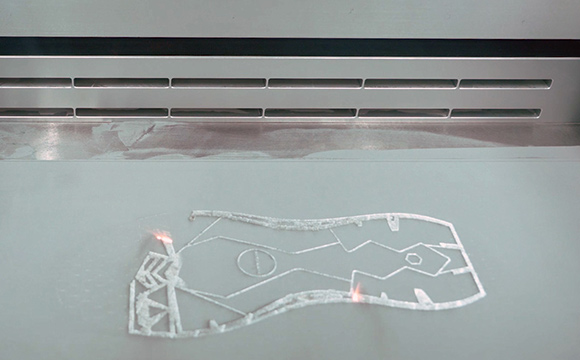

Automotive Heat Exchanger

Machine: FS200M-2

Material: Aluminum

Minimum wall thickness: 0.2 mm

Partner: SAPW

This heat exchanger for automotive featuring many complicateddesign elements including internal channels and thin wall structures inorder to meet the required functionality. Compared to the traditionalmachining and welding method, the additive technology offerssimplified manufacturing process boosts structural integrationimproved life span, and faster design to market time.

Our Product raw materials

Photosensitive resin( Domestic&Import&Transparent)

Material optional color:

White&Light green&Black&Transparent

Laser-cured resins can be used to produce products with high precision, clear boundaries and smooth surfaces

Even if the raw materials are available in few primary colors, the printing ability is strong, and it can produce products with translucent or even full transparency effects

Plastic(ABS&PLA)

Environmentally friendly and durable entry-level material.

Single molding volume are about to 1100*860*880MM

Low precision(Not higher than 0.2mm)

Commonly used to make prototypes of mechanical parts.

General design requirements can not have too much cantilever structure

Nlyon with high strength and high tenacity

Material optional color: White&Black

·More comprehensive

·

Multipurpose

·

Less design restrictions

·

No need to consider supporting structures

·

One-piece molding can be achieved if your moving parts and mating parts are properly designed.

·

High material strength

·

Have a certain degree of flexibility

·

It can produce a functional end product .

Including various complex designs

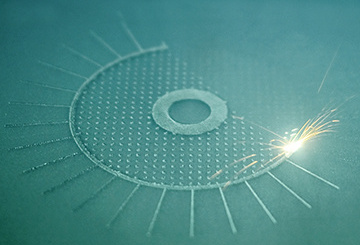

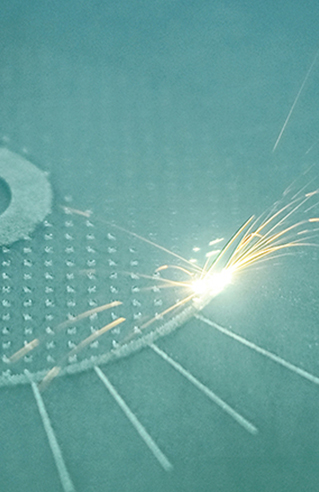

Metal(Aluminum&Iron&Titanium)

Metal printing is achieved by laser sintering metal powder. Rough surface of machined finished products.

However, after post-processing, engineering metal structural parts can be achieved.

Finished surface polishing effect is good

Product Display

Focusing on high precision

Hot Searches