- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

20

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

heating element

-

Grade:

-

Ni,Cr

-

Ni (Min):

-

76%

-

Model Number:

-

Cr20Ni80

-

Brand Name:

-

DLX

-

Surface:

-

Bright

-

Process method:

-

Drawing And Rolling

-

Treatment:

-

Hydrogen Annealing

-

Condition:

-

Soft Annealed

-

MOQ:

-

3kgs

-

Melting point:

-

1400℃

-

Certificate:

-

ISO,ROHS

-

Delivery time:

-

7-25 days

Quick Details

-

Resistance (μΩ.m):

-

1.09±0.05

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

637

-

Elongation (≥ %):

-

20

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

heating element

-

Grade:

-

Ni,Cr

-

Ni (Min):

-

76%

-

Model Number:

-

Cr20Ni80

-

Brand Name:

-

DLX

-

Surface:

-

Bright

-

Process method:

-

Drawing And Rolling

-

Treatment:

-

Hydrogen Annealing

-

Condition:

-

Soft Annealed

-

MOQ:

-

3kgs

-

Melting point:

-

1400℃

-

Certificate:

-

ISO,ROHS

-

Delivery time:

-

7-25 days

Products Description

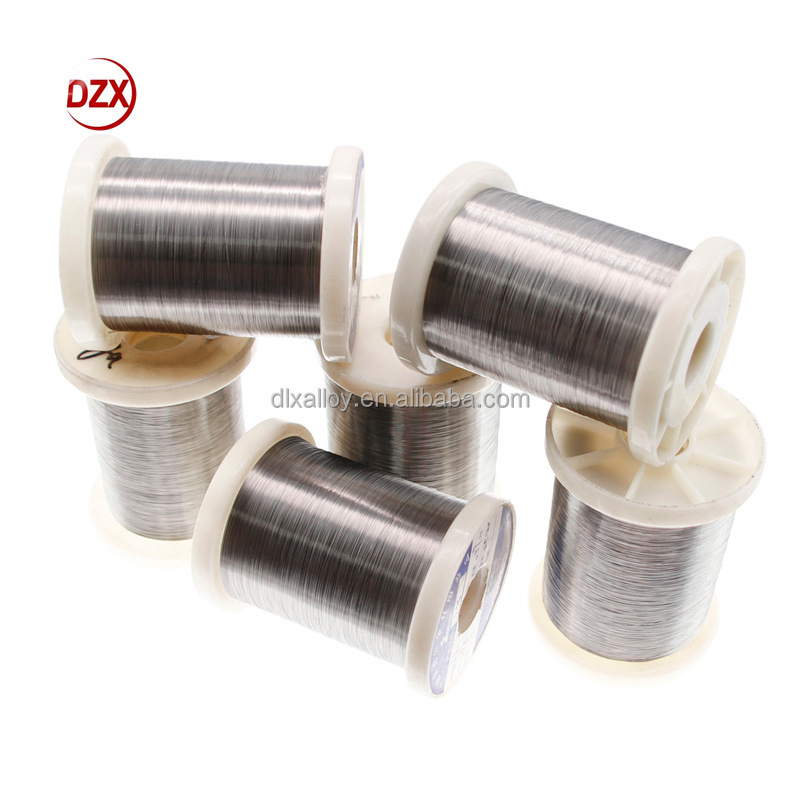

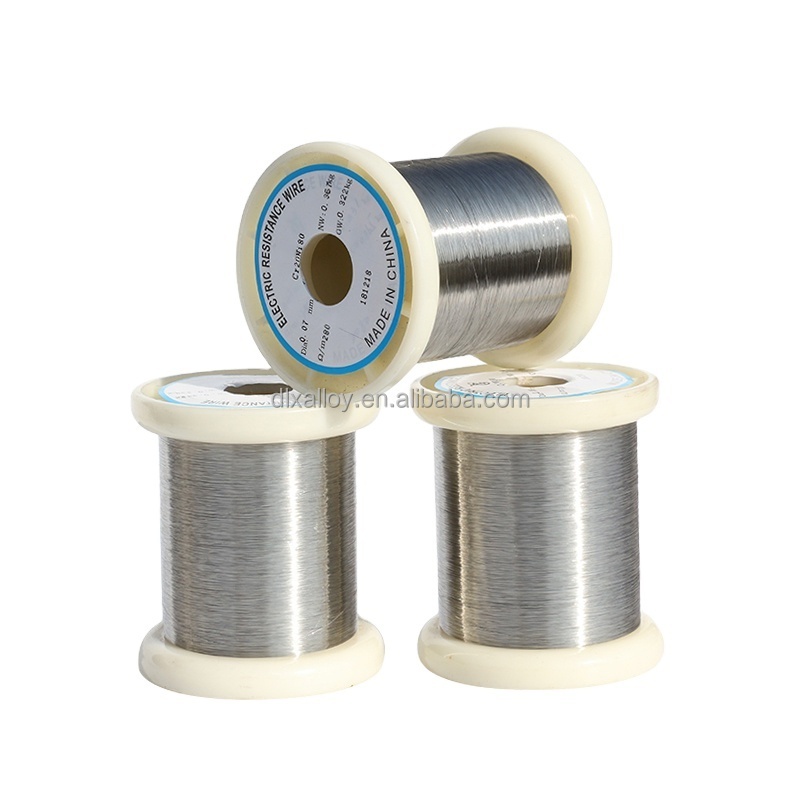

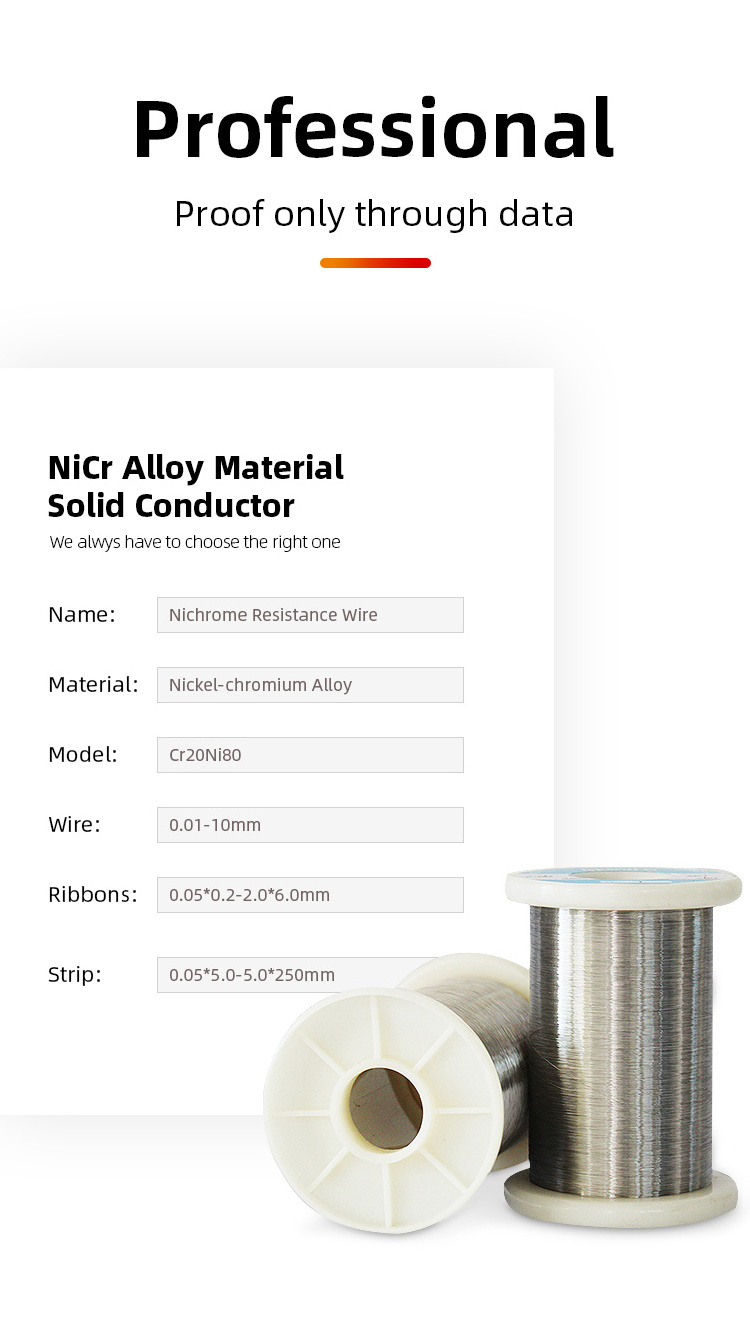

Cr20Ni80 Nichrome 80 Alloy wire

Nickel-chromium Alloy with high and stable resistance, corrosion resistance, surface oxidation resistance, excellent coil-forming ability.

Cr20Ni80 is an ideal material, it has good ductility,workability and weldability under high temperature and seismic strength.

Nickel-chromium alloy with high and stable resistance, corrosion resistance, surface oxidation resistance, excellent coil-forming ability.

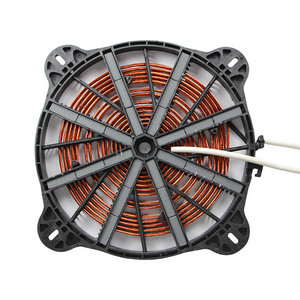

Application of NiCr wire

NiCr heating wire is widely used for making electric heating elements in home appliances and industrial furnaces. Typical

applications are flat irons, ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular

elements and cartridge elements.

Feature of NiCr Alloy

(1)High resistance

(2)Low temperature coefficient of resistance

(3)High working temperature

(4)Good corrosion resistance especailly under high temperature

(5)Good performance of anti-carburizing, the atmosphere and surface of sulfur pollution.

(6)Long useful life

(1)High resistance

(2)Low temperature coefficient of resistance

(3)High working temperature

(4)Good corrosion resistance especailly under high temperature

(5)Good performance of anti-carburizing, the atmosphere and surface of sulfur pollution.

(6)Long useful life

Application of NiCr wire

NiCr heating wire is widely used for making electric heating elements in home appliances and industrial furnaces. Typical

applications are flat irons, ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular

elements and cartridge elements.

It can be widely used in industrial furnacess, household appliances and far-infrared devices.

Specification

|

Performance\ material

|

|

Cr20Ni80

|

|

|

Composition

|

Ni

|

Rest

|

|

|

|

Cr

|

20.0~23.0

|

|

|

|

Fe

|

≤1.0

|

|

|

Maximum temperature℃

|

|

1200

|

|

|

Meltiing point ℃

|

|

1400

|

|

|

Density g/cm3

|

|

8.4

|

|

|

Resistivity

|

|

1.09±0.05

|

|

|

μΩ·m,20℃

|

|

|

|

|

Elongation at rupture

|

|

≥20

|

|

|

Specific heat

|

|

0.44

|

|

|

J/g.℃

|

|

|

|

|

Thermal conductivity

|

|

60.3

|

|

|

KJ/m.h℃

|

|

|

|

|

Coefficient of lines expansion

|

|

18

|

|

|

a×10-6/

|

|

|

|

|

(20~1000℃)

|

|

|

|

|

Micrographic structure

|

|

Austenite

|

|

|

Magnetic properties

|

|

Nonmagnetic

|

|

Features

Quality Control,

Safer when Heating Treatment

Long Service Life,

High Strength, Not easy to break

High percentage of nickel content,

High Strength, Not easy to break

Widely Use

This alloys are widely used in making industrial heating equipments and domestic heating appliances.Heat treatment furnaces,far infrared heating devices,starting and braking resistors for electrically driven locomotive,liquified gas infrared heat resistant nets and tail gas purifiers for auto car are the main applications in the industrial field.Do-mestic applications are such as cooking,ironing,drying,heating of fluids,heating of beds,space heating and etc.

Recommend Products

About Us

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Customized service

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Hot Searches