- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

90 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Ranking

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

100*72*120cm

-

Power (kW):

-

4 kW

-

Function:

-

Mixer Blender

-

Machine Type:

-

Mixng Machine

-

Application scope:

-

High Viscosity Product

-

Motor:

-

Domestic

-

Capacity:

-

100-300L

Quick Details

-

Barrel Volume (L):

-

5000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 3000 r.p.m

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

90 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Ranking

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

100*72*120cm

-

Power (kW):

-

4 kW

-

Function:

-

Mixer Blender

-

Machine Type:

-

Mixng Machine

-

Application scope:

-

High Viscosity Product

-

Motor:

-

Domestic

-

Capacity:

-

100-300L

Product Description

Specification

|

Modle

|

Power(kw)

|

Speed(rpm)

|

Handing Capacity(L)

|

D

|

D1

|

P

|

L

|

M

|

|

WRL-70

|

0.75

|

3000

|

10~30L

|

80

|

145

|

200

|

300

|

165

|

|

WRL-90

|

1.5

|

2800

|

10-50

|

80

|

145

|

200

|

550

|

165

|

|

WRL-100

|

2.2

|

2800

|

50-100

|

88

|

145

|

200

|

650

|

165

|

|

WRL-120

|

4

|

2800

|

100-300

|

100

|

180

|

250

|

700

|

215

|

|

WRL-140

|

7.5

|

2800

|

300-800

|

120

|

210

|

300

|

900

|

265

|

|

WRL-160

|

11

|

2800

|

500-1500

|

160

|

230

|

350

|

1050

|

300

|

|

WRL-180

|

18.5

|

2800

|

600-2000

|

180

|

260

|

350

|

1200

|

300

|

|

WRL-200

|

22

|

1400

|

800-2500

|

200

|

270

|

350

|

1200

|

300

|

|

WRL-220

|

30

|

1400

|

1000-3500

|

220

|

300

|

400

|

1355

|

350

|

|

WRL-240

|

45

|

1400

|

1500-5000

|

260

|

340

|

450

|

1395

|

400

|

|

WRL-270

|

55

|

1400

|

2000-8000

|

290

|

390

|

550

|

1600

|

500

|

|

WRL-290

|

75

|

1400

|

3000-10000

|

320

|

420

|

550

|

1650

|

500

|

Notice:

high shear mixer homogenizing mixer prices listed in this page may not uptodate or only for the lowest configered product or for

parts of the mixer.Please contact our online service team to get the latest price and professional service.

Spices mixing sanitary grade Stainless Steel 304 ss316L High Shear Batch Emulsifier Machine

Characteristics

1. high speed rotor and stator, claw-type work head and many other mixing head design optional.

2. Bidirectional suction, superfine dispersion and homogenization of the materials with high shearing efficiency.

3. Customized lifting stand, Hydraulic lift, screw manual lift, manual chain lift or pneumatic lift stand optional

4. Stable performance, low noise, convenient cleaning, and continuous operation with flexibility and mobility.

5. Working temperature <180℃

6. Safe and reliable explosion proof option.

7. Mobile tanks are available 50~500Liters

8. bottom mount homogenizer avaliable

9. liner mixer liner homogenizing pump available

Purpose:

Using for sanitizer gel emulsifying and homogenizing

ethyl alcohol gel cream lotion shapoo body cream high shear mixing

Advantage:

1.Superfinely dispersing and emulsifying

2.Stable operation

3.Less noise

4.Cleaning easily

Applicable Industries:

food, mining, paper-making, water treatment fine chemicals, cosmetic etc.

How the Batch High Shear Mixer Works

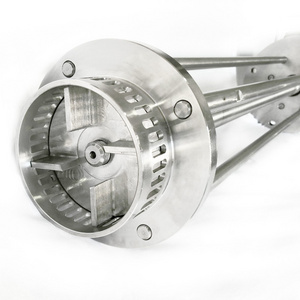

The Batch High Shear Mixer design consists of a single stage four-blade rotor that turns at high speed within a stationary stator.

As the rotating blades pass each opening in the stator, they mechanically shear particles and droplets, and expel material at high

velocity into the surrounding mix, creating intense hydraulic shear. As fast as material is expelled, more is drawn into the

bottom of the rotor/stator generator, which promotes continuous flow and fast mixing.

Spices mixing sanitary grade Stainless Steel 304 ss316L High Shear Batch Emulsifier Machine

Characteristics

1. high speed rotor and stator, claw-type work head and many other mixing head design optional.

2. Bidirectional suction, superfine dispersion and homogenization of the materials with high shearing efficiency.

3. Customized lifting stand, Hydraulic lift, screw manual lift, manual chain lift or pneumatic lift stand optional

4. Stable performance, low noise, convenient cleaning, and continuous operation with flexibility and mobility.

5. Working temperature <180℃

6. Safe and reliable explosion proof option.

7. Mobile tanks are available 50~500Liters

8. bottom mount homogenizer avaliable

9. liner mixer liner homogenizing pump available

Purpose:

Using for sanitizer gel emulsifying and homogenizing

ethyl alcohol gel cream lotion shapoo body cream high shear mixing

Advantage:

1.Superfinely dispersing and emulsifying

2.Stable operation

3.Less noise

4.Cleaning easily

Applicable Industries:

food, mining, paper-making, water treatment fine chemicals, cosmetic etc.

How the Batch High Shear Mixer Works

The Batch High Shear Mixer design consists of a single stage four-blade rotor that turns at high speed within a stationary stator.

As the rotating blades pass each opening in the stator, they mechanically shear particles and droplets, and expel material at high

velocity into the surrounding mix, creating intense hydraulic shear. As fast as material is expelled, more is drawn into the

bottom of the rotor/stator generator, which promotes continuous flow and fast mixing.

Packing & Delivery

Related products Vedio

Hot Searches