- Product Details

- {{item.text}}

Quick Details

-

MF:

-

SiO2.x(H2O)

-

EINECS No.:

-

238-878-4

-

Place of Origin:

-

Guangdong, China

-

Appearance:

-

White powder

-

Application:

-

Multifunctional

-

Product name:

-

White Carbon Black

-

Color:

-

White

-

production process:

-

percipitation

-

CAS:

-

10279-57-9

-

SiO2 content:

-

96

-

Grade:

-

Industrial grade

-

PH value:

-

6.5-7.5

-

Oil absorption (DIN EN ISO 787-5):

-

360-380

-

Particle size:

-

400

-

Delivery Time:

-

7days

Quick Details

-

CAS No.:

-

10279-57-9

-

Purity:

-

92%

-

Other Names:

-

SiO2

-

MF:

-

SiO2.x(H2O)

-

EINECS No.:

-

238-878-4

-

Place of Origin:

-

Guangdong, China

-

Appearance:

-

White powder

-

Application:

-

Multifunctional

-

Product name:

-

White Carbon Black

-

Color:

-

White

-

production process:

-

percipitation

-

CAS:

-

10279-57-9

-

SiO2 content:

-

96

-

Grade:

-

Industrial grade

-

PH value:

-

6.5-7.5

-

Oil absorption (DIN EN ISO 787-5):

-

360-380

-

Particle size:

-

400

-

Delivery Time:

-

7days

Inorganic Hydrated silica powder fumed silica price

Product Description

Silica

Silica is also known as hydrated silica. The chemical formula is SiO2·nH2O. It is a white, non-toxic, amorphous and fine powdered inorganic silicon compound with porosity, high dispersibility, light weight, and good chemical stability. It has excellent properties such as high temperature resistance, non-combustibility, and good electrical insulation. It has been widely used in many fields such as plastics, rubber, papermaking, coatings, dyes and inks.

|

Name

|

Precipitated Silica

|

|

Appearance

|

White Color powder

|

|

Production Process

|

Precipitation

|

|

Degree of White

|

≥97

|

|

SiO2 content(dry basis)%

|

≥96

|

|

PH Value

|

6.5-7.5

|

|

Specific surface area (㎡/g)

|

200-220

|

|

Oil absorption value (ml/100g)

|

360-380

|

|

Dry reduction (150℃,2h)%

|

4.0-5.0

|

|

Burn reduction (950℃,2h)%

|

6.0-8.0

|

|

Particle Size (nm)

|

400

|

Classification of Silica

There are two ways to classify Silica,

According to the manufacturing method

, it is divided into precipitated silica and meteorological silica;

According to the market

, silica is divided into meteorological silica, ordinary precipitated silica and highly dispersed precipitated silica.

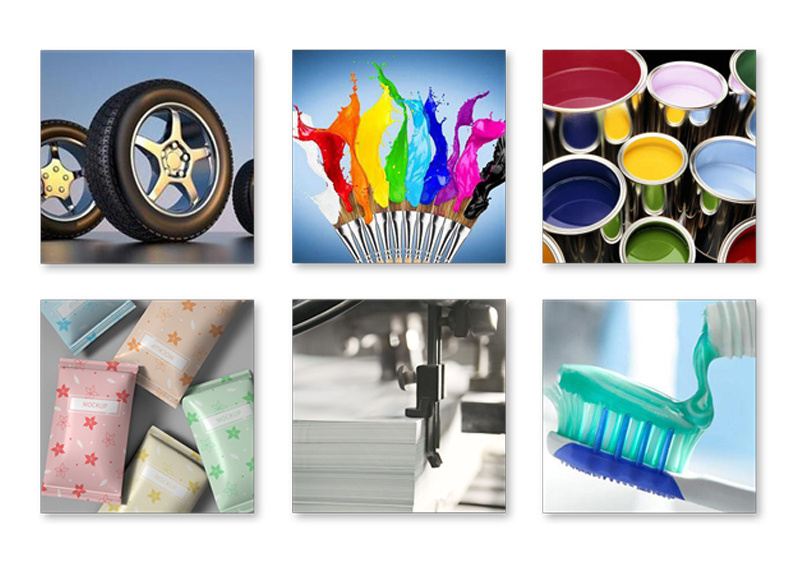

Application

In tires

Silica is used as a reinforcing agent, and the largest amount is in the rubber field, which accounts for 70% of the total. White carbon black can greatly improve the physical properties of the rubber, reduce the lag of the rubber, and reduce the rollin resistance of the tire without losing its wet skid resistance. In the rubber industry, carbon black is a very effective reinforcing agent.

Adding silica to the tread rubber of tires can improve the cutting and tear resistance of the tread, and reduce popping and falling blocks. Compared with the rubber filled with white carbon black, the rolling resistance can be reduced by 30%.

In paint, coating

Silica can be used as a rheological additive, anti-settling agent, auxiliary dispersant, and matting agent in paint production,and has the functions of thickening, anti-settling, thixotropy, and matting. It can also improve the weather resistance and scratch resistance of the coating, increase the adhesion strength between the coating and the substrate and the hardness of the coating, improve the anti-aging property of the coating, and improve the UV absorption and infrared light reflection characteristics.

In Plastic

Silica is also often used in new plastics. Adding a small amount of white carbon black during plastic mixing will have a significant reinforcing effect, improve the hardness and mechanical properties of the material, thereby improving the processing technology and the performance of the product. In addition, white carbon black has the characteristics of small particle size and high light transmittance, which can make the plastic more dense and increase the transparency of the plastic.

In papermaking

In the paper industry, fumed silica products can be used as a paper sizing agent, can improve the whiteness and opacity of paper,and can improve oil resistance, abrasion resistance, feel, printability, and gloss. It can also be used for printing drawings,which can make the surface of the paper good, the ink is stable, and the back is free of cracks. It can also be used in azide paper to produce excellent blue drawings, which can be used in copper paper to replace titanium dioxide. Adding 1-2% fumed silica product can reduce the weight of the paper, and the paper is thin, can improve the strength, prevent ink penetration, can also make the printed text clear and increase the opacity.

Our Company

Hot Searches