boxes, apple trays, i ndustry packing paper products , lamp holder , coffee paper holder ,l ined with supporting paper holder , fruit portion trays, strawberry punnets, kidney trays, wine packs, can trays, seed pots, seed cubes, etc.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380 V or other require

-

Power:

-

32-100KW

-

Dimension(L*W*H):

-

15*2.7*3.5 meter

-

Weight:

-

5000 kg

-

Marketing Type:

-

small business

-

Raw material:

-

Wast book/newspaper/carton and wood pulp/straw pulp

-

Finished Products:

-

Egg Tray, Egg Carton, Fruit Tray, Shoe Tray, Wine Tray, Cup Tray

-

Drying way:

-

Natural drying, brick kiln drying, metal dryer

-

Drying fuel:

-

coal, wood, diesel, natural gas, lp-gas

-

Mould material:

-

Plastic or Aluminium

-

Capacity:

-

1000-8000pcs/hour

-

Automation:

-

Fully Atuomatic

-

Color:

-

Customized Color

-

Mould type:

-

6 cells,10 cells,12 cells,18 cells,30cells or customized

-

Function:

-

small egg tray production line

Quick Details

-

Production Capacity:

-

20 PCS/MIN

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NH

-

Voltage:

-

220V/380 V or other require

-

Power:

-

32-100KW

-

Dimension(L*W*H):

-

15*2.7*3.5 meter

-

Weight:

-

5000 kg

-

Marketing Type:

-

small business

-

Raw material:

-

Wast book/newspaper/carton and wood pulp/straw pulp

-

Finished Products:

-

Egg Tray, Egg Carton, Fruit Tray, Shoe Tray, Wine Tray, Cup Tray

-

Drying way:

-

Natural drying, brick kiln drying, metal dryer

-

Drying fuel:

-

coal, wood, diesel, natural gas, lp-gas

-

Mould material:

-

Plastic or Aluminium

-

Capacity:

-

1000-8000pcs/hour

-

Automation:

-

Fully Atuomatic

-

Color:

-

Customized Color

-

Mould type:

-

6 cells,10 cells,12 cells,18 cells,30cells or customized

-

Function:

-

small egg tray production line

Product Overview

Customized paper pulp equipment wine glass tray machinery coaster and egg trays pulp forming environmentally friendly equipment

Small egg tray production line /eggs packaging boxes carton tray equipment

paper pulp equipment wine glass tray machinery coaster trays pulp forming machine

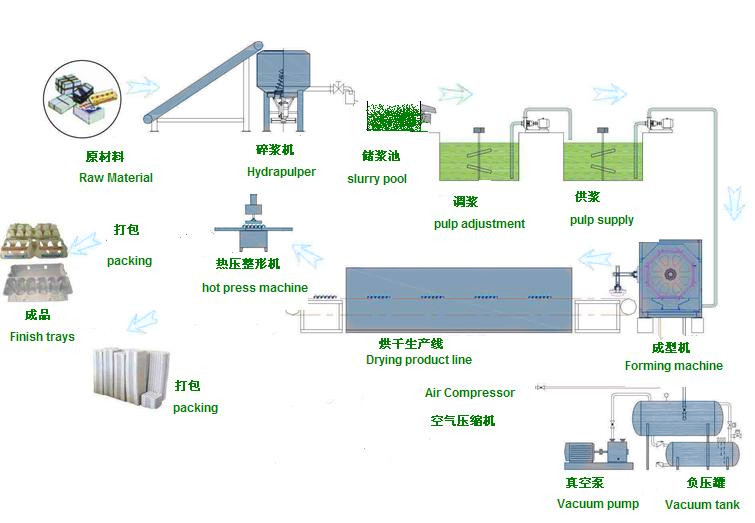

uses waste paper as raw materials to produce different kinds of products according to your requirements, such as egg trays, egg cartons, egg boxes, apple trays, fruit trays, industrial trays, seeding trays etc. Our machine includes pulp making system ,forming system and drying system

FEATURES AT A GLANCE

Customized paper pulp equipment wine glass tray machinery coaster and egg trays pulp forming environmentally friendly equipment

use all kinds of waste paper to produce high quality molded fibre products. Such as, egg trays, egg

boxes, apple trays, i ndustry packing paper products , lamp holder , coffee paper holder ,l ined with supporting paper holder , fruit portion trays, strawberry punnets, kidney trays, wine packs, can trays, seed pots, seed cubes, etc.

boxes, apple trays, i ndustry packing paper products , lamp holder , coffee paper holder ,l ined with supporting paper holder , fruit portion trays, strawberry punnets, kidney trays, wine packs, can trays, seed pots, seed cubes, etc.

PRODUCT SPECIFICATIONS

|

Machine Model

|

3*1

|

4*1

|

3*4

|

4*4

|

4*8

|

5*8

|

5*12

|

6*12

|

|

Yield(p/h)

|

1500

|

2000

|

2500

|

3000

|

4000

|

5000

|

6000

|

8000

|

|

Waste Paper(kg/h)

|

120

|

160

|

200

|

280

|

320

|

400

|

480

|

640

|

|

Water(kg/h)

|

300

|

380

|

450

|

560

|

560

|

750

|

750

|

1040

|

|

Electricity(kw/h)

|

32

|

45

|

58

|

78

|

80

|

80

|

90

|

100

|

|

Workshop Area

|

45

|

80

|

80

|

100

|

100

|

140

|

180

|

250

|

|

Drying Area

|

Natural drying

|

216

|

216

|

216

|

216

|

238

|

260

|

300

|

PRODUCT CONFIGURATION

1.Pulping system

Put the raw material into the pulper and add an appropriate amount of water for a long time to stir the waste paper into pulp and store it in the storage tank.

2. Forming system

After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product

is blown from the molding die to the rotary mold, and is sent out by the transfer mold.

3. Drying system

(1) Natural drying method: The product is dried directly by weather and natural wind.(2) Traditional drying: brick tunnel kiln,

heat source can choose natural gas, diesel, coal, dry wood

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy

4. Finished product auxiliary packaging

(1) Automatic stacking machine

(2) Baler

(3) Transfer conveyor

Put the raw material into the pulper and add an appropriate amount of water for a long time to stir the waste paper into pulp and store it in the storage tank.

2. Forming system

After the mold is adsorbed, the transfer mold is blown out by the positive pressure of the air compressor, and the molded product

is blown from the molding die to the rotary mold, and is sent out by the transfer mold.

3. Drying system

(1) Natural drying method: The product is dried directly by weather and natural wind.(2) Traditional drying: brick tunnel kiln,

heat source can choose natural gas, diesel, coal, dry wood

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy

4. Finished product auxiliary packaging

(1) Automatic stacking machine

(2) Baler

(3) Transfer conveyor

SALES AND SERVICE NETWORK

Why Choose Us

Qinyang NH Paper Machinery Industrial Group Co., Ltd

specializing in pulp molding equipment, Our machines can produce a wide variety of packaging products ranging from egg tray packaging to electronic components packaging and more .

SIMILAR PRODUCTS

FAQ

Q1:

What kinds of

Small egg tray production line /eggs packaging boxes carton tray equipment paper pulp equipment wine glass tray machinery coaster trays pulp forming machine

moulds do you produce?

A1:

We produce all kinds of pulping mold, such as egg tray molds,egg box molds,fruit tray molds,coffee cup tray molds,wine tray molds,

industrial package mold etc

,customzied paper pulp mould products .

Q2: How to install the mold of

Small egg tray production line /eggs packaging boxes carton tray equipment paper pulp equipment wine glass tray machinery coaster trays pulp forming machine

?

A2: We have professional technician guidance to assist you with installation.

A2: We have professional technician guidance to assist you with installation.

Q3: How should I choose the model of

Small egg tray production line /eggs packaging boxes carton tray equipment paper pulp equipment wine glass tray machinery coaster trays pulp forming machine

?

A3: 1. You could tell us your request for select our existing model or newly designed mould. There are popular used moulds and also can make customzied moulds as your sample or the drawing .

2. There are plastic and aluminum moulds for you choose .Please tell us your requirement of : raw material , capacity , finished producs . So we will help you design right production line for you .

A3: 1. You could tell us your request for select our existing model or newly designed mould. There are popular used moulds and also can make customzied moulds as your sample or the drawing .

2. There are plastic and aluminum moulds for you choose .Please tell us your requirement of : raw material , capacity , finished producs . So we will help you design right production line for you .

Hot Searches