- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SUPER or OEM

-

Dimension(L*W*H):

-

7200*1100*1700mm

-

Weight (KG):

-

13000

-

Type:

-

sheet metal folding machine

-

Folding Materials:

-

MS, SS

-

Usage:

-

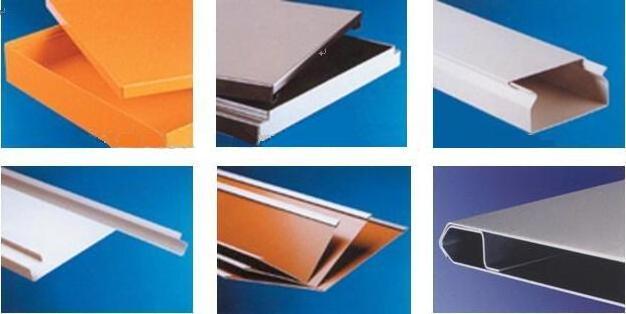

HVAC Duct Working , Metal roof making

-

Folding Angle:

-

0~120 degree

-

Back gauge range:

-

500mm (or according customer request)

-

Name:

-

Automatic Folding Machine

-

Motor Power:

-

2.2~5.5KW

-

Open Height:

-

110mm

-

Certification:

-

ce

Quick Details

-

Bending Thickness(mm):

-

1 - 2 mm

-

Bending Length(mm):

-

6400 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUPER or OEM

-

Dimension(L*W*H):

-

7200*1100*1700mm

-

Weight (KG):

-

13000

-

Type:

-

sheet metal folding machine

-

Folding Materials:

-

MS, SS

-

Usage:

-

HVAC Duct Working , Metal roof making

-

Folding Angle:

-

0~120 degree

-

Back gauge range:

-

500mm (or according customer request)

-

Name:

-

Automatic Folding Machine

-

Motor Power:

-

2.2~5.5KW

-

Open Height:

-

110mm

-

Certification:

-

ce

Products Description

Full Automatic CNC Sheet Metal Folding Machine

Structural & Operating Features;

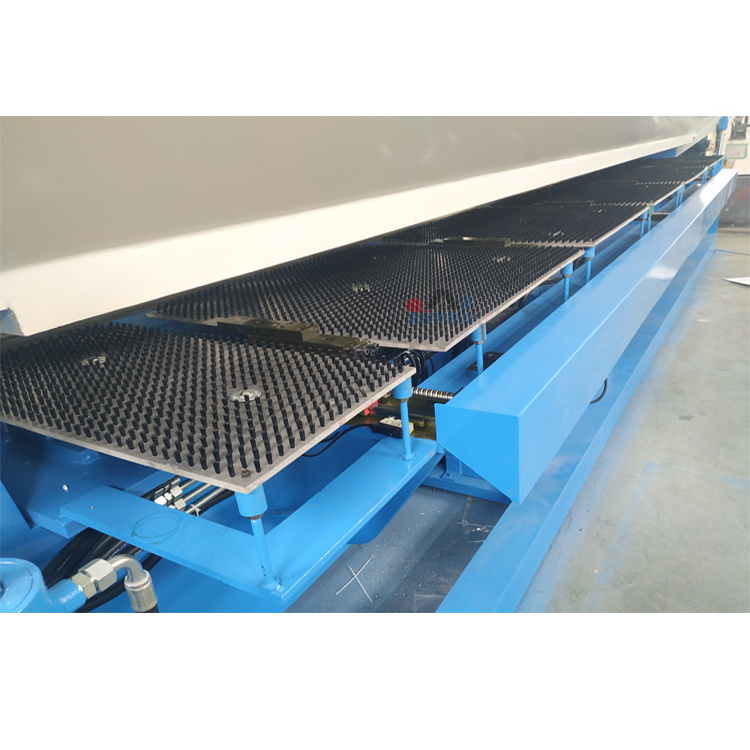

* Hydraulically operated folding and clamping beam for efficient heavy duty operation.

* High Structural Rigidity from Heavy Plate steel box construction with continuous welded seams.

* Folding beam powered by dual hydraulic cylinders.

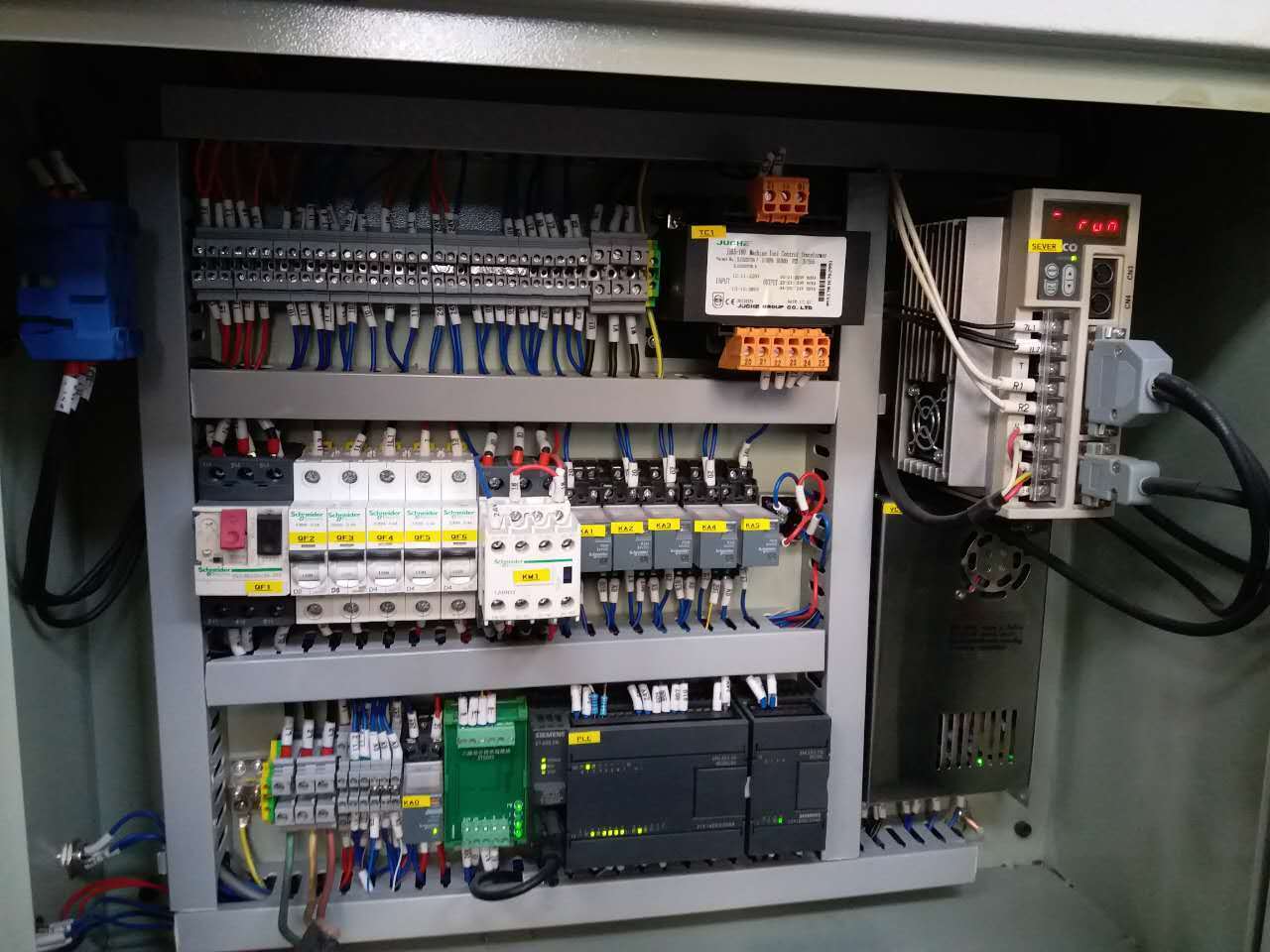

* Fully integrated and enclosed electric/ hydraulic system with large oil reservoir.

* High load dual spherical plane bearings utilized at folding beam pivots and over-centre clamp bearings.

* Precise electric/ hydraulic controls with manual inching of folding beam.

* Utilization of easy to set micro-switches provides accurate adjustable angle control to the folding apron.

* Comprehensive equipment protection from electric and hydraulic overload systems

Hydraulic System;

* High quality components ensure reliable performance for years of continuous operation

* Powerful direct coupled hydraulic pump and motor provides efficient, rapid operation.

* Unique electric/ hydraulic control ensures safe and simple operation.

Specifications;

* Up to 4000 mm folding length available - Capacity 4.0 to 6.0 mm available

* High bending angle of 0-135° - Up to 145mm depth of box bent - Up to 150mm lift of clamping beam

* 24V control wiring – segmented folding tools made from hardened material maximizing life

* Instruction, Hydraulic and Electrical Manuals – CE Marked

* Hydraulically operated folding and clamping beam for efficient heavy duty operation.

* High Structural Rigidity from Heavy Plate steel box construction with continuous welded seams.

* Folding beam powered by dual hydraulic cylinders.

* Fully integrated and enclosed electric/ hydraulic system with large oil reservoir.

* High load dual spherical plane bearings utilized at folding beam pivots and over-centre clamp bearings.

* Precise electric/ hydraulic controls with manual inching of folding beam.

* Utilization of easy to set micro-switches provides accurate adjustable angle control to the folding apron.

* Comprehensive equipment protection from electric and hydraulic overload systems

Hydraulic System;

* High quality components ensure reliable performance for years of continuous operation

* Powerful direct coupled hydraulic pump and motor provides efficient, rapid operation.

* Unique electric/ hydraulic control ensures safe and simple operation.

Specifications;

* Up to 4000 mm folding length available - Capacity 4.0 to 6.0 mm available

* High bending angle of 0-135° - Up to 145mm depth of box bent - Up to 150mm lift of clamping beam

* 24V control wiring – segmented folding tools made from hardened material maximizing life

* Instruction, Hydraulic and Electrical Manuals – CE Marked

Feature

* 14′-1″ bending width, 14 gauge maximum thickness

* Box and Pan upper clamp

* Advanced Computer Control

* Draw desired shape on touch screen, adjust lengths and angles, adjust bend sequence, save part, run part, bend part. Very easy to use.

* Servo controlled Backgauge

* Light curtain – safety device

* Video of operation available

* CE&ISO 9001:2000.

* Box and Pan upper clamp

* Advanced Computer Control

* Draw desired shape on touch screen, adjust lengths and angles, adjust bend sequence, save part, run part, bend part. Very easy to use.

* Servo controlled Backgauge

* Light curtain – safety device

* Video of operation available

* CE&ISO 9001:2000.

Options

*

E21s control panel

* Rear ball roller table

* Back gauge extend

* Pnematic back gauge block finger

Product Paramenters

|

Model

|

Capacity(mm)

|

Folding angle(

o

)

|

Open Height(mm)

|

Motor Power(kw)

|

Net Weight(kg)

|

Dimension (L*W*H)(mm)

|

|

W62K

|

2*2500

|

0~120

|

110

|

2.2

|

1700

|

3300x850x1550

|

|

W62K

|

2*3200

|

0~120

|

110

|

2.2

|

3600

|

4100x1550x1550

|

|

W62K

|

3*2500

|

0~120

|

110

|

4

|

3100

|

3450x1130x1800

|

|

W62K

|

3*3200

|

0~120

|

110

|

4

|

3800

|

4150x1130x1800

|

|

W62K

|

3*4000

|

0~120

|

110

|

4

|

6100

|

4900x1150x1900

|

|

W62K

|

4*1320

|

0~120

|

110

|

4

|

1800

|

2270x1130x1800

|

|

W62K

|

4*2000

|

0~120

|

110

|

4

|

2500

|

2900x1130x1700

|

|

W62K

|

5*2500

|

0~120

|

110

|

5.5

|

4000

|

3500x1130x1800

|

|

W62K

|

5*3200

|

0~120

|

110

|

5.5

|

5500

|

4150x1130x1900

|

|

W62K

|

2*4300

|

0~120

|

110

|

4

|

6100

|

5400*1150*1650

|

|

W62K

|

1.5*6300

|

0~120

|

110

|

5.5

|

12000

|

7100*1850*1650

|

Graphic touch panel (standard)

Button panel (optional)

Digital read out panel (optional)

Standard back gauge (servo motor drive , linear guide and ball screw)

Main motor(siemens), magnetic valve (rexroth),hydraulic system

Electric componet(Schneider) , PLC+touch screen (Xinjie)

CNC folding brake samples

Sheet metal box and pan folding brake machine options:

A. Hydraulic with manual back gauge

B. 1-axis digital CNC for bending angle / back gauge with manual back gauge / bending angle.

C. 2-axis graphic CNC for bending angle and back gauge

B. 1-axis digital CNC for bending angle / back gauge with manual back gauge / bending angle.

C. 2-axis graphic CNC for bending angle and back gauge

Recommend Products

Hot Searches