- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

varies according models

-

Weight:

-

10020 KG, 10t

-

Name:

-

Ball Mill

-

Model:

-

1200*2400

-

Ball Loading:

-

4t

-

Application:

-

Gold Ore Grinding

-

Speed:

-

35.1rpm

-

Max feeding size:

-

25mm

-

Capacity:

-

2 t/h

-

Motor:

-

37kw

-

Dimension:

-

5540*2300*1850mm

Quick Details

-

Capacity(t/h):

-

2 t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXWKD

-

Dimension(L*W*H):

-

varies according models

-

Weight:

-

10020 KG, 10t

-

Name:

-

Ball Mill

-

Model:

-

1200*2400

-

Ball Loading:

-

4t

-

Application:

-

Gold Ore Grinding

-

Speed:

-

35.1rpm

-

Max feeding size:

-

25mm

-

Capacity:

-

2 t/h

-

Motor:

-

37kw

-

Dimension:

-

5540*2300*1850mm

Product Description

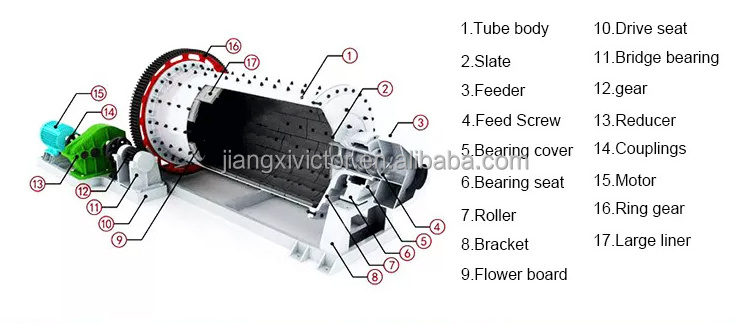

Ball mill is the key equipment for grinding after crushing Widely used in mineral processing, building materials and others.Ball mill can divide into 2 types, wet ball mill and dry ball mill. Ball mill is a mineral processing machine for milling the materials into powders after they are crushed. It is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and ferrous metal processing industries.

Ball Mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industry. Ball Mills can grind various ores and other materials either wet or dry, depending on requirements. Ball Mills consist of a large cylinder which slowly rotates around a horizontal axis. The cylinder is partially filled with the material to be ground plus the grinding medium (metal grinding balls). Inside the cylinder, the medium will be lifted to a certain height under the action of centrifugal force and then drop or fall, grinding the ore in between the balls as they interact. Feed material to be ground enters the cylinder via a hopper on one end and after being crushed by the grinding medium is discharged at the other end.

Technical Parameters

|

Model

|

Speed (r/min)

|

Ball Loading (t)

|

Feeding Size (mm)

|

Capacity (t/h)

|

Motor (kw)

|

Weight (kg)

|

|

Φ900*1200

|

41.6

|

1.1

|

25

|

0.3-0.9

|

11

|

4210

|

|

Φ900*1800

|

41.6

|

1.8

|

25

|

0.6-1.5

|

18.5

|

6660

|

|

Φ1200*2400

|

35.1

|

4.0

|

25

|

1.6-4.1

|

37

|

10020

|

|

Φ1300*3000

|

30.2

|

5.2

|

25

|

2.0-4.5

|

45

|

11290

|

|

Φ1500*3000

|

30.7

|

9

|

25

|

3.5-8.0

|

80

|

16843

|

|

Φ1500*4000

|

30.7

|

11.11

|

25

|

4.8-10.5

|

110

|

19103

|

|

Φ1500*4500

|

30.7

|

13.5

|

25

|

5.5-13.5

|

130

|

20000

|

|

Φ1830*3000

|

25.04

|

13

|

25

|

3.0-17.0

|

130

|

29490

|

|

Φ1830*4500

|

25.04

|

19

|

25

|

5.2-26.0

|

180

|

34210

|

|

Φ2100*3000

|

23.8

|

20

|

25

|

4.0-30.0

|

180

|

41965

|

|

Φ2100*4000

|

23.8

|

22

|

25

|

5.2-39.0

|

245

|

46697

|

|

Φ2100*4500

|

23.8

|

23.8

|

25

|

5.2-40.0

|

245

|

47000

|

|

Φ2400*4000

|

23

|

30

|

25

|

7.0-92

|

320

|

67984

|

|

Φ2400*6000

|

23

|

40

|

25

|

10-120

|

320

|

73365

|

|

Φ2700*4500

|

21.7

|

42

|

25

|

19-150

|

475

|

100000

|

Details Images

Package & shipment

Package: FCL & LCL export standard container 20GP/40GP/40HQ.

FCL: main machinery in nude package and bulk in container, spare parts in wooden box or as your special requirement

LCL: machinery are packed in iron frame.

Shipment: by sea shipment.

Payment Terms:

T/T is preferable.

T/T: 30% deposit and the balance before delivery

we will take photos for your products when finished and show you before delivery. Also keep you informed for any updated information including shipping before you receive it, to let you rest assured

Delivery time: shipped in 15-20 days after deposit received!!!

Project Case

Related Products

Spiral Classifier

Hydrocyclone

Hot Searches