- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

prefab modular concrete house

-

Suitable for:

-

fast saaembly buildings

-

Application Site:

-

House/Hotel/ Restaurant/Villa Construction

-

Advantages:

-

low cost, quick build, anti-earthquake, insulation

-

After-sales Service:

-

offer engineer to install and training for 30 days at least

-

Raw materials:

-

Reinforced concrete

-

Needed machine 1:

-

Making Machine,Quick-solidifying Machine, CNC Rebar Machine

-

Needed machine 2:

-

Concrete Mixer, Batching Machine, Assembled Storage Tank

-

Keywords 1:

-

precast modular house

-

Keywords 2:

-

concrete prefab house

Quick Details

-

Weight (KG):

-

20000

-

Core Components:

-

motor

-

Place of Origin:

-

Hubei, China

-

Product name:

-

prefab modular concrete house

-

Suitable for:

-

fast saaembly buildings

-

Application Site:

-

House/Hotel/ Restaurant/Villa Construction

-

Advantages:

-

low cost, quick build, anti-earthquake, insulation

-

After-sales Service:

-

offer engineer to install and training for 30 days at least

-

Raw materials:

-

Reinforced concrete

-

Needed machine 1:

-

Making Machine,Quick-solidifying Machine, CNC Rebar Machine

-

Needed machine 2:

-

Concrete Mixer, Batching Machine, Assembled Storage Tank

-

Keywords 1:

-

precast modular house

-

Keywords 2:

-

concrete prefab house

Product Overview

Concrete Modular House

Concrete modular house is also called precast concrete house,

prefab concrete modular house or

cement prefab modular house

, which is belonging to concrete assembly building method.It is a new type of construction method to save much construction cost.

It adopts reinforced concrete structure, which is prefabricated into unit modules in the factory through special equipment, and then directly transported to the site for assembly. The level of prefabrication is high, the size is accurate, the construction speed is fast, and 500 square meters can be built in one day, which greatly increases the construction speed

Compared with traditional brick and concrete houses, the main advantages of

concrete prefab modular house

are low construction cost, good earthquake resistance, long service life, fast construction speed, labor saving , long lifetime, no leaving construction rubbish, and can be removed when demolition.

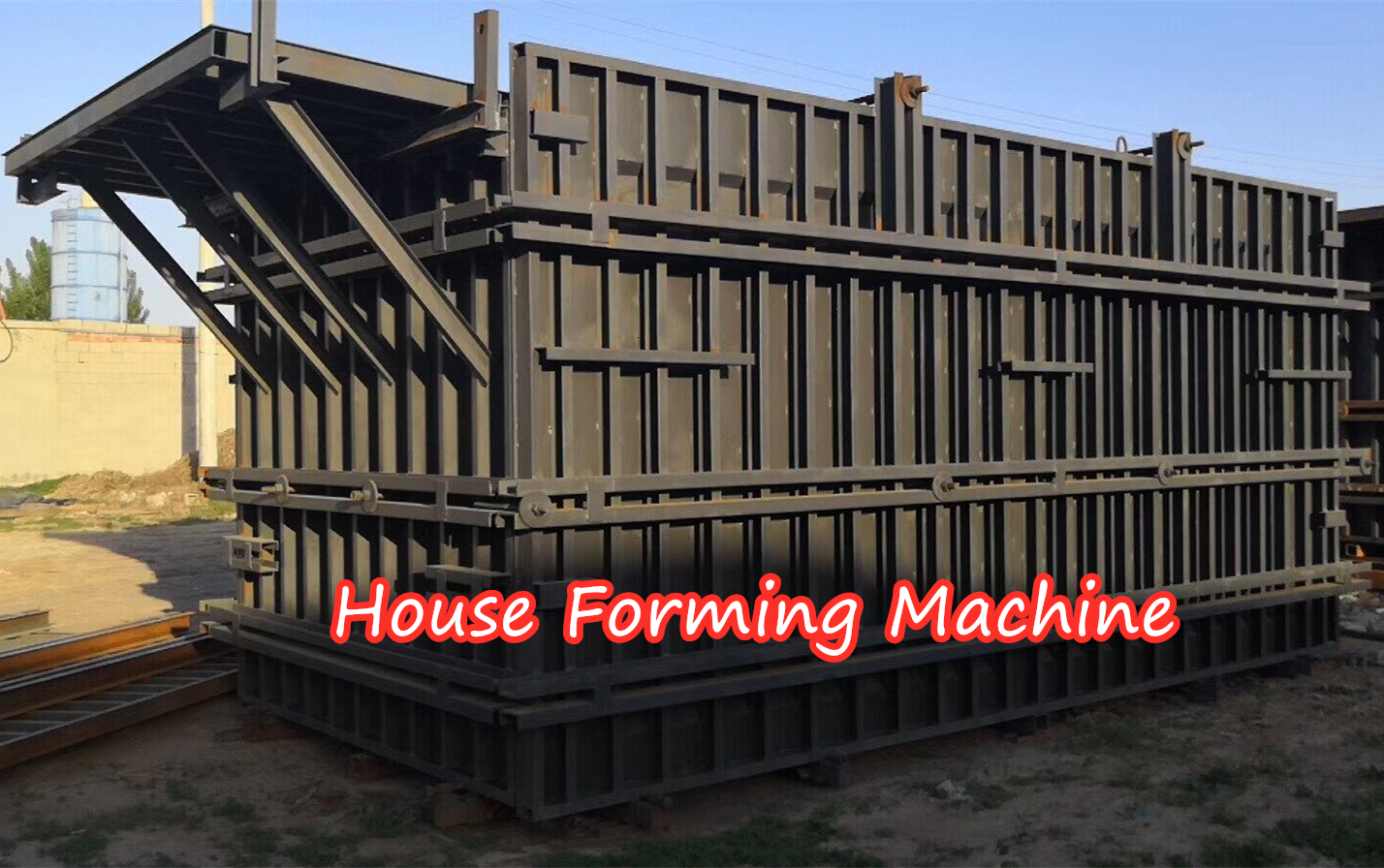

Equipment Line

How to produce?

Single concrete unit produced with equipment

Different productivity, different machine combination

|

Scale

|

Configuration

|

Maximum Productivity

|

|

Type Ⅰ :

Economical-type Equipment Group (For clients with insufficient budget |

1Set Modular House Forming Machine

1Set Modular House Steaming Machine A 1Set CNC Rebar Processing Machines Accessories And Tools |

30 Units Modular House/ Month

(Above 300 Units / Year) |

|

Type Ⅱ :

Small-scale Productivity Equipment Group

|

2Set Modular House Forming Machines

1Set Modular House Steaming Machine B

1Set CNC Rebar Processing Machine

1Set Concrete Mixer 1Set Batching Machine A

1Set Assembled Storage Tank A

Other Parts For Concrete Equipment

Accessories And Tools

|

60 Units Modular House/ Month

(Above 600 Units / Year) |

|

Type Ⅲ :

Middle-scale Productivity Equipment Group

|

4Set Modular House Forming Machines

1Set Modular House Steaming Machine C

1Set CNC Rebar Processing Machine

1Set Concrete Mixer 1Set Batching Machine B

1Set Assembled Storage Tank B

Other Parts For Concrete Equipment

Accessories And Tools

|

120 Units Modular House/ Month

(Above 1200 Units / Year) |

|

Type Ⅳ :

Large-scale Productivity Equipment Group |

8Set House Forming Machine

2Set Modular House Steaming Machine C

2Set CNC Rebar Processing Machine

1Set Concrete Mixer 1Set Batching Machine B

1Set Assembled Storage Tank B

Other Parts For Concrete Equipment

Accessories And Tools

|

240 Units Modular House/ Month

(Above 2400 Units / Year) |

Successful Project

Project of 1 storey

Project of 2 storey

Project of 3 storey

Project of 4 storey

Project of 4 storey

Project of 5 storey

FAQ

Q1:

What is the common size and floorage of each concrete module? What is the wall and roof thickness of the concrete modular ?

A1:t

he common sizes of one unit concrete module are: Width*Length: 3*6m, 3.3*6.3m , 3.3*6.6m, 3.5*7m, 3.6*6.3m ,3.6*6.6m, 3.6*7.2m. common height : 3m or 3.1m.

So the floor area of a common size concrete module is from 18 square meters to 28 square meters. The length of front eaves can be adjusted From 0 to 1.5m .

Q2:

What's the production cost of producing 1 modular house?

A2:

The cost of self-produced concrete is about 57.1USD / cubic meter (raw materials: cement, sand, stone, water). The cost of steel bars is 428.5USD / ton = 0.428USD / KG.

Take a 3.3 * 6.6 * 3 meter (about 22 square meters) module unit as an example

The amount of material is as follows: 8.5 cubic meters of concrete: 400 * 8.5 = 485.7USD

420KG Steel bar: 420 * 0.428= 180 USD

Water and Electricity costs: 42.85USD

Labor cost:71.43USD

The total cost of a modular unit (about 22 square meters) = 780USD

So the cost per square meter = 780 ÷ 22 = 35.45 USD per square meter

Q3:

Do you provide a guarantee for your

prefab modular concrete house

machines?

A3:

We provide 1 years warranty for machines, and will also preapre free spare parts

Q4:

What is your payment terms for the buyer?

A4:

30% T / T deposit, 70% T / T balance before loading

How to Contact Us?

Mobile / WHATSAPP: +86-18674058216

Email: cecilia@buildhouse123.com

Hot Searches