- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CONSMOS

-

Model Number:

-

CONSMOS-FFP

-

Product name:

-

Black Film Faced Plywood Marine Construction Formwork WBP Phenolic

-

Size:

-

1220x2440mm, 1250x2500mm or custom

-

Thickness:

-

9-25mm

-

Core:

-

Combi core, poplar core, eucalyptus core, birch core etc.

-

Density:

-

550-700 kg/m3 (+/- 50 kg)

-

Glue:

-

MR, Melamine, WBP

-

Thickness tolerance:

-

+/-0.5mm

-

Moisture Content:

-

10% (+/- 2%)

-

Modulus of Elasticity:

-

≥6000Mpa

-

Certification:

-

CE, ISO9001, FSC, CARB etc.

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

graphic design

-

Application:

-

Construction

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CONSMOS

-

Model Number:

-

CONSMOS-FFP

-

Product name:

-

Black Film Faced Plywood Marine Construction Formwork WBP Phenolic

-

Size:

-

1220x2440mm, 1250x2500mm or custom

-

Thickness:

-

9-25mm

-

Core:

-

Combi core, poplar core, eucalyptus core, birch core etc.

-

Density:

-

550-700 kg/m3 (+/- 50 kg)

-

Glue:

-

MR, Melamine, WBP

-

Thickness tolerance:

-

+/-0.5mm

-

Moisture Content:

-

10% (+/- 2%)

-

Modulus of Elasticity:

-

≥6000Mpa

-

Certification:

-

CE, ISO9001, FSC, CARB etc.

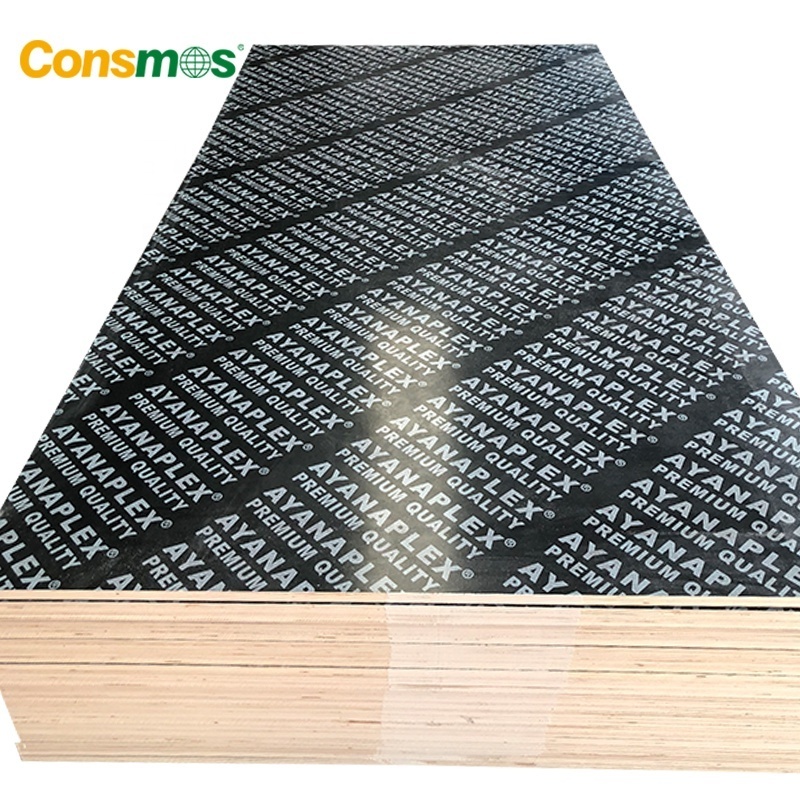

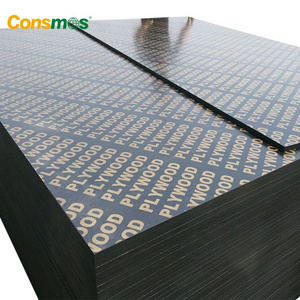

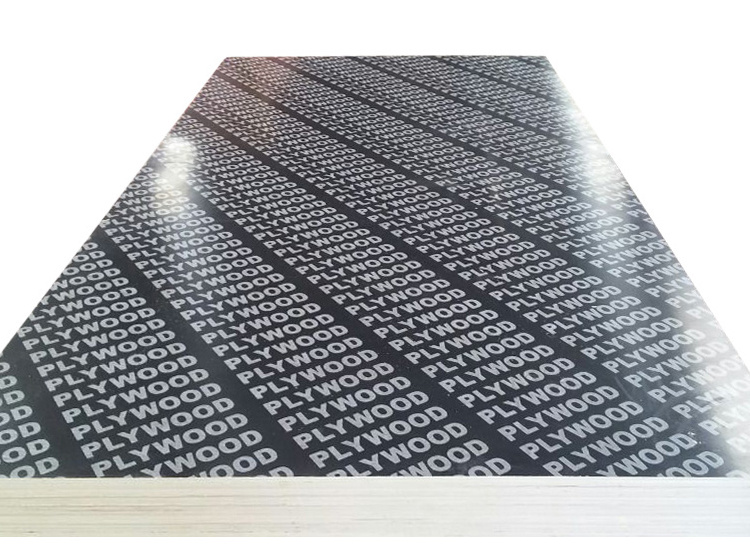

Consmos 1220x2440mm 18mm Black Film Faced Plywood Marine Construction Formwork WBP Phenolic Board

Products Description

|

Product name

|

Consmos 1220x2440mm 18mm Black Film Faced Plywood Marine Construction Formwork WBP Phenolic Board

|

|

Brand

|

CONSMOS

|

|

Size

|

1220x2440mm, 1250x2500mm or custom

|

|

Thickness

|

9-25mm

|

|

Core

|

Combi core, poplar core, eucalyptus core, birch core etc.

|

|

Density

|

550-700 kg/m3 (+/- 50 kg)

|

|

Glue

|

MR, Melamine, WBP

|

|

Thickness tolerance

|

+/-0.5mm

|

|

Moisture Content

|

10% (+/- 2%)

|

|

Modulus of rupture

|

≥30Mpa

|

|

Modulus of Elasticity

|

≥6000Mpa

|

|

Certification

|

CE ISO9001 FSC CARB

|

|

Usages

|

Construction

|

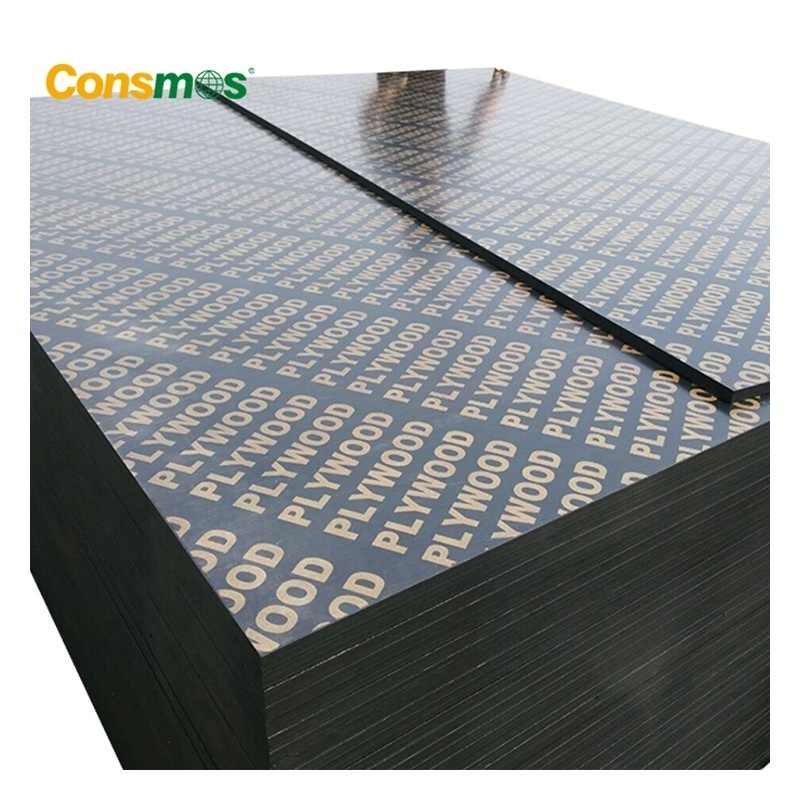

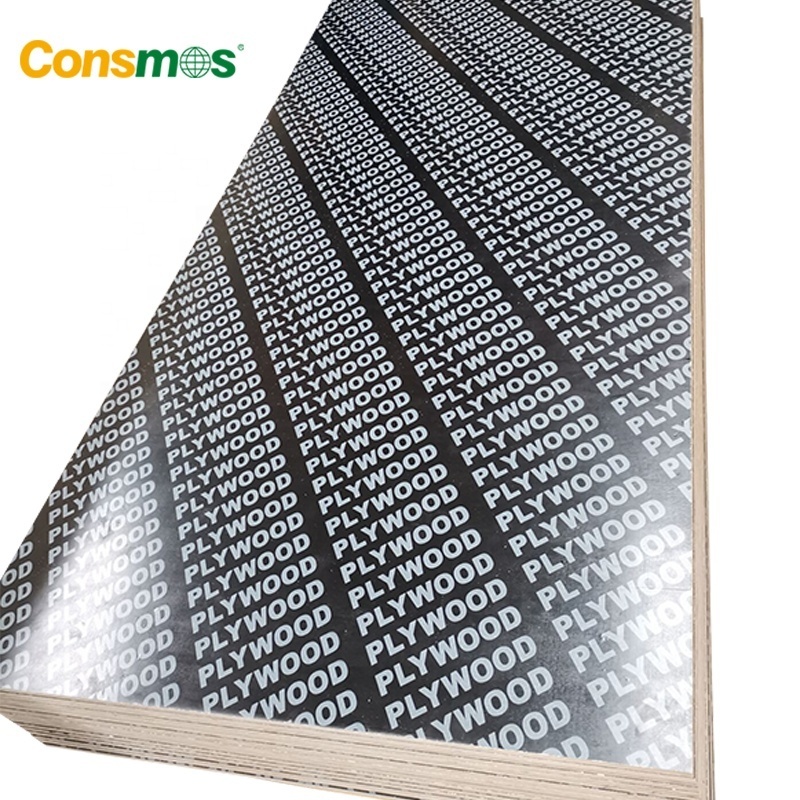

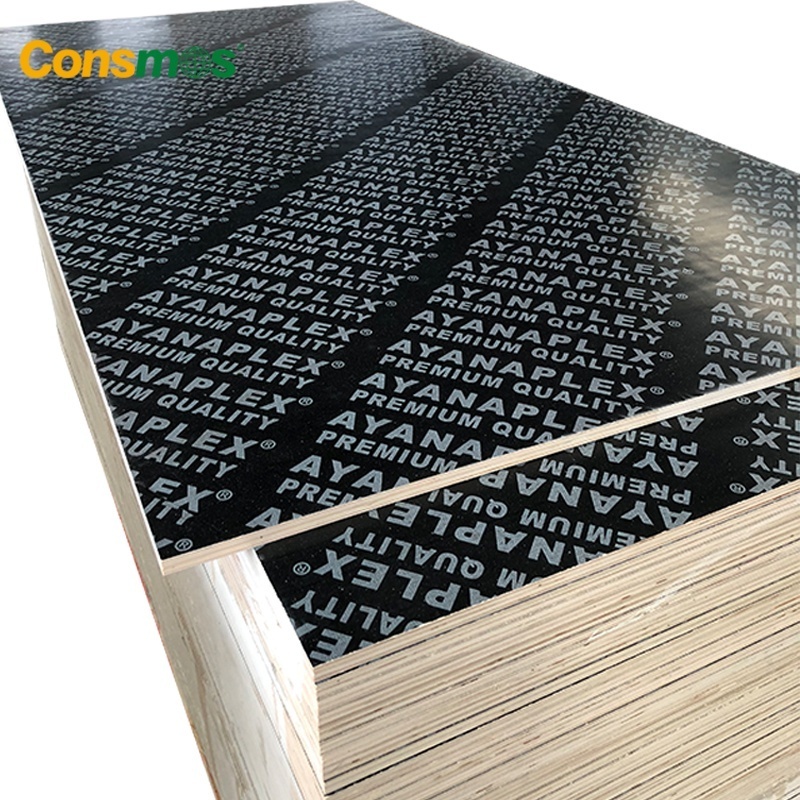

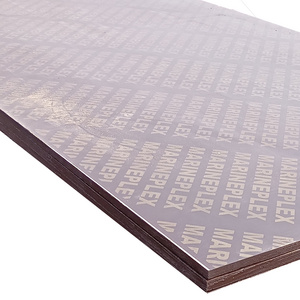

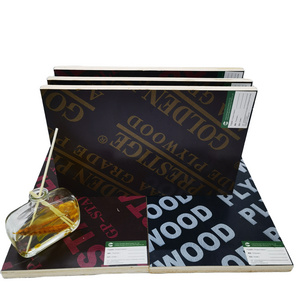

Product Display

FILM FACED PLYWOOD

1.No wapping, no fracture, not out of shape, it can stay 24 hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful, so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and it will not pollute the surface of concrete.

7.It is good to keep performance warm, is favorable to make construction in winter.

8.Products can be made into warping plywood.

9.It is better to nail,saw,drill than bamboo and steel mould, it can be processed into different types.

Quality Control

We have 15 QC teams to inspection such as moisture control, glue inspection both before production and after production, material grade selection, pressing checking, and thickness checking.

Application

Hot Searches