- Product Details

- {{item.text}}

Quick Details

-

Max Sewing Thickness:

-

1200g one square metre

-

Voltage:

-

220V/380V

-

Power:

-

3000W

-

Dimension(L*W*H):

-

4.9*1.8*2.35m

-

Weight:

-

2000

-

Product name:

-

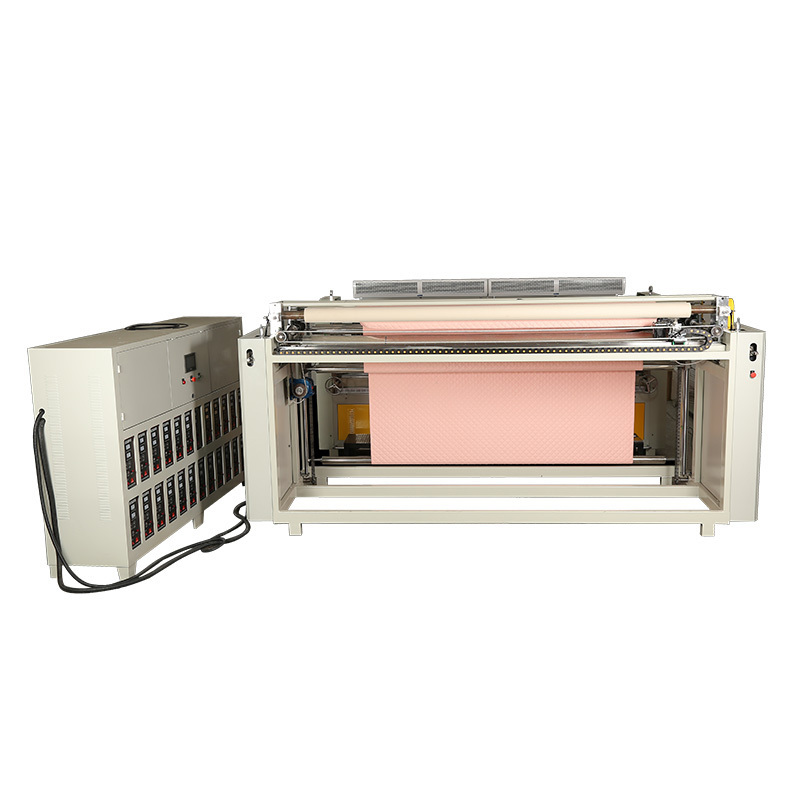

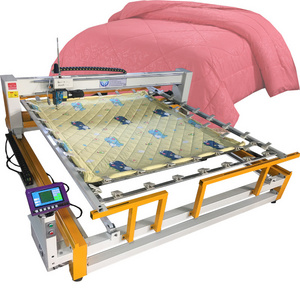

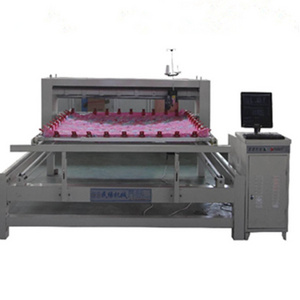

one head quilt making machine quilting ultrasonic machine

-

Usage:

-

seaming with no threads and needles

-

Working temperature:

-

below 25 degree

-

Advantage:

-

Ultrasonic control box with strong and stable power

-

Length of the roll:

-

1300MM

-

Touch display:

-

7 inches

-

Sewing machine:

-

Long Arm Quilting Single

-

Model:

-

Quilting Size

-

Suitable for:

-

Bed Cover Quilt Sewing Machine

-

Application:

-

Widely Used

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Max Sewing Speed:

-

30m/min

-

Max Sewing Thickness:

-

1200g one square metre

-

Voltage:

-

220V/380V

-

Power:

-

3000W

-

Dimension(L*W*H):

-

4.9*1.8*2.35m

-

Weight:

-

2000

-

Product name:

-

one head quilt making machine quilting ultrasonic machine

-

Usage:

-

seaming with no threads and needles

-

Working temperature:

-

below 25 degree

-

Advantage:

-

Ultrasonic control box with strong and stable power

-

Length of the roll:

-

1300MM

-

Touch display:

-

7 inches

-

Sewing machine:

-

Long Arm Quilting Single

-

Model:

-

Quilting Size

-

Suitable for:

-

Bed Cover Quilt Sewing Machine

-

Application:

-

Widely Used

Duvet Quilting Machine Pillow And Quilt Roll Press Packing Machine Full Automatic Ultrasonic Quilting Machines

Feature

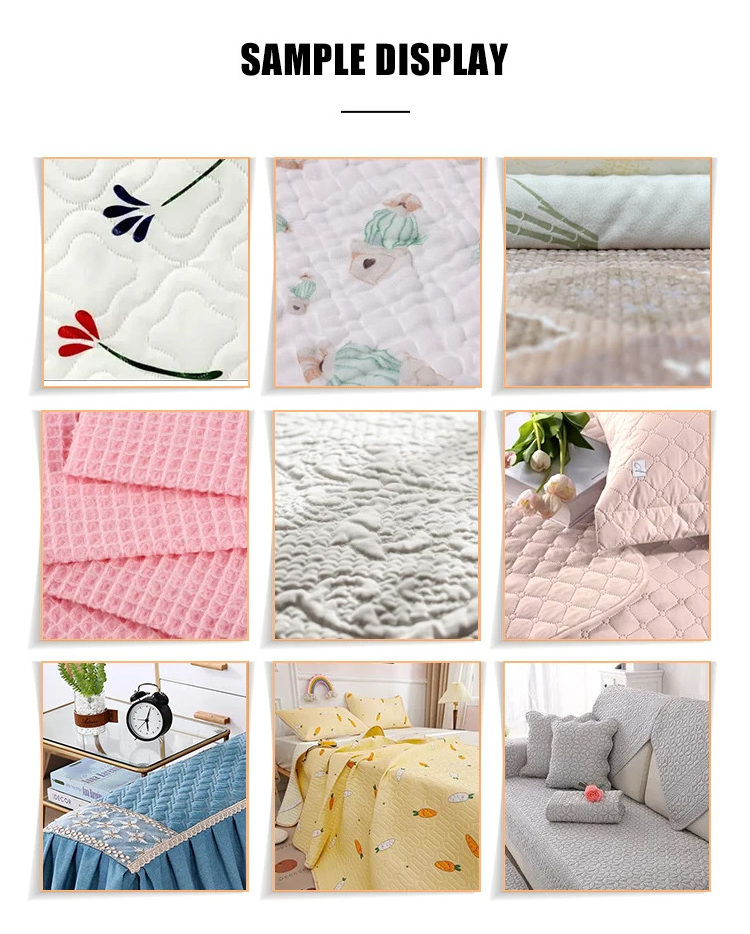

1- Adopt ultrasonic technology to weld and stitch the fabric together without needle and thread.

2- High speed and high productivity, strong welding strength, stable quality.

3- Different rollers and patterns can be designed according to different material and different products requirements.

4- Special structured design, easy adjustment and easy roller replacement.

5- Humanity control design, easy to operate and understand.

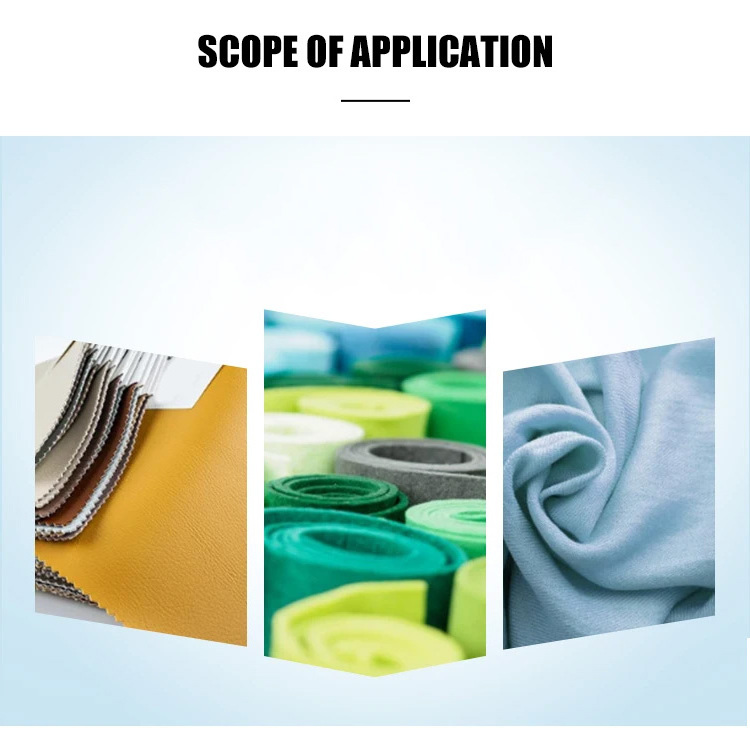

Applications

Producing the compounding of spout gum cotton, non-woven fabrics and needle cotton with chemical fiber fabrics, artificial leather

products. It is applied to the production of mattress, multi-cover, bedcover, bed sheet, blanket, seat cushion, winter jacket,

robes, polo cases, apron, sleeping bag, show jacket, car seat cover.

1- Adopt ultrasonic technology to weld and stitch the fabric together without needle and thread.

2- High speed and high productivity, strong welding strength, stable quality.

3- Different rollers and patterns can be designed according to different material and different products requirements.

4- Special structured design, easy adjustment and easy roller replacement.

5- Humanity control design, easy to operate and understand.

Applications

Producing the compounding of spout gum cotton, non-woven fabrics and needle cotton with chemical fiber fabrics, artificial leather

products. It is applied to the production of mattress, multi-cover, bedcover, bed sheet, blanket, seat cushion, winter jacket,

robes, polo cases, apron, sleeping bag, show jacket, car seat cover.

Product Description

Packing & Delivery

Hot Searches