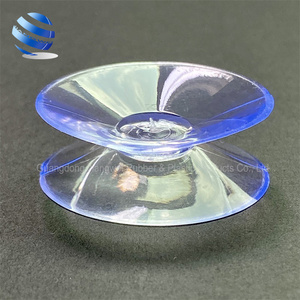

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM

-

Product name:

-

customize customize Silicone Rubber Parts Rubber Product Factory

-

Design::

-

Customized

-

Color::

-

Any color available

-

Hardness::

-

20~80 shore A

-

Size::

-

Large,Medium,Small

-

Material::

-

Food grade silicone

-

Advantage::

-

Washable

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

OEM

-

Product name:

-

customize customize Silicone Rubber Parts Rubber Product Factory

-

Design::

-

Customized

-

Color::

-

Any color available

-

Hardness::

-

20~80 shore A

-

Size::

-

Large,Medium,Small

-

Material::

-

Food grade silicone

-

Advantage::

-

Washable

Product Description

Specification

|

Part Name:

|

customize Silicone Rubber Parts Rubber Product Factory

|

|

company Type:

|

Manufacturer/ Factory

|

|

One-Stop service:

|

Mold-making,prototyping,production,surface treatment,assembly,packing

|

|

Material Demand:

|

Solid Silicone; Liquid Silicone; Rubber

|

|

Material Grade:

|

Food Grade;Medical Grade;High Elastic;High Transparent

|

|

Moldling Technology:

|

Compression Molding; Injection Molding; LSR Overmolding

|

|

Certificate:

|

RoHS,REACH; ISO 9001; ISO14001; Green Partner

|

|

Drawings:

|

3D(step, iges, stl file); 2D(pdf, dxf, dwg file)

|

|

Color:

|

Customize Pantone Color

|

|

Dimension:

|

Based on clients' design drawing

|

|

Design:

|

Based on clients' design drawing

|

|

Feature:

|

Based on clients' design drawing and requirements

|

|

Package:

|

Original pack:Inner PE bag outer master carton; or Customize packing

|

|

Shipping:

|

By air; By express DHL/UPS/FEDEX etc.; By sea from Shenzhen port

|

|

Leadtime:

|

Prototyping around 7~15 days after paymen

|

|

Payment Term:

|

Payment term: Paypal; T/T; Western Union; L/C

.Mold Cost: 100% prepaid; Goods: 50% deposit, 50% balance

|

FAQ

|

How to Start One-stop Customized Service

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

What Information do we Need for Evaluating Mold Cost and Unit Price?

|

|

|

|

|

||||

|

1)3D drawing (step, iges, stl file.); 2D drawing( pdf, dwg, dxf file) or samples

|

|

|

|

|

||||

|

2)Materials demands: solid silicone; liquid silicone; rubber

|

|

|

|

|

||||

|

3)Materials grade demands: food grade;medical grade;high elastic;high transparent

|

|

|

|

|

||||

|

4)Hardness or durometer demands: 10~80 Shore A

|

|

|

|

|

||||

|

5)Color demands: based on pantone color

|

|

|

|

|

||||

|

6)Surface treatment demands

|

|

|

|

|

||||

|

7)Packing demands

|

|

|

|

|

||||

|

8)Order quantity demands

|

|

|

|

|

||||

|

What kind of Silicone Rubber Parts and Products do we OEM/ Customize?

|

|

|

|

|

||||

|

Silicone Smart Electronics Wearables, Silicone Keypad Buttons, Silicone Cover Cases, Baby Care

|

|

|

|

|

||||

|

Medical Silicone Products, Beauty Care, Silicone Rubber Sealings, Kitchen Sanitary Silicone Products

|

|

|

|

|

||||

|

Sports Silicone Products, Conductive Silicone Rubber, Insulated Silicone, Silicone Promotion Gifts

|

|

|

|

|

||||

|

LSR Overmolded Parts and Products, Rubber Banded Metal, Silicone Rubber Extrusion, Adult Products

|

|

|

|

|

||||

Dongguan

GuangHong Silicone Rubber Products Co.,Ltd. established in 1994. which is specialize in customize OEM manufacture different industries silicone rubber products and parts like electronic Industry,medical Industry,kitchen sanitary Industry and baby care products etc.we're an ISO14001:2015, ISO9001:2015, Green Partner accredited factory; the material using all with REACH,ROHS, SGS reports.

Our Factory

experienced technical persons and engineers have been working here since 1994. and we have silicon compression molded

production plant with 30 machines,LSR injection production plant with 5 machines and Liquid silicone rubber overmolding line.andwe offer one-Stop service: mold-making, molding production, surface treatment, assembly, packing and shipping.

Traditional silicone rubber compression molding:

Silicone rubber compression molding is traditional production method, using traditional silicone rubber compression machines. it is a cost-effective choice for many simple parts and products.

High Precision Liquid Silicone Injection Molding :

LSR Injection Mould is also called Liquid Silicone Rubber Injection Moulding, LSR Injection Mold & LIM, which can produce liquid silicone rubber parts or products by injection molded machines; by liquid silicon rubber injection mould production, which is safer, perfect parting line, more precise, environmentally friendly and transparent; It is capable of efficiently producing a large number of versatile items, including isolators, waterproof electronic contact sealings, beauty care products and baby care products.

Complex Design LSR Overmolding :

LSR overmolding is our factory core competitiveness. LSR overmolding process involves two steps where in a completed plastic or metal entity is placed into the mold site of an LSR mold; after which the LSR is overmolded directly onto the part. one of the benefits of LSR overmolded parts and products is that the manufacturing process allows for the use of a non-plastic substrate. It is important to note that overmolding is the only way to incorporate materials, aside from other thermoplastics and LSRs, into the injection molding process. LSR overmolded handles to complex electronic assemblies,it is excellent for meeting the complex design requirements of the automotive and medical industries.

production plant with 30 machines,LSR injection production plant with 5 machines and Liquid silicone rubber overmolding line.andwe offer one-Stop service: mold-making, molding production, surface treatment, assembly, packing and shipping.

Traditional silicone rubber compression molding:

Silicone rubber compression molding is traditional production method, using traditional silicone rubber compression machines. it is a cost-effective choice for many simple parts and products.

High Precision Liquid Silicone Injection Molding :

LSR Injection Mould is also called Liquid Silicone Rubber Injection Moulding, LSR Injection Mold & LIM, which can produce liquid silicone rubber parts or products by injection molded machines; by liquid silicon rubber injection mould production, which is safer, perfect parting line, more precise, environmentally friendly and transparent; It is capable of efficiently producing a large number of versatile items, including isolators, waterproof electronic contact sealings, beauty care products and baby care products.

Complex Design LSR Overmolding :

LSR overmolding is our factory core competitiveness. LSR overmolding process involves two steps where in a completed plastic or metal entity is placed into the mold site of an LSR mold; after which the LSR is overmolded directly onto the part. one of the benefits of LSR overmolded parts and products is that the manufacturing process allows for the use of a non-plastic substrate. It is important to note that overmolding is the only way to incorporate materials, aside from other thermoplastics and LSRs, into the injection molding process. LSR overmolded handles to complex electronic assemblies,it is excellent for meeting the complex design requirements of the automotive and medical industries.

Hot Searches