- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/440V(or customized)

-

Power:

-

20-50kw

-

Weight:

-

1280 KG

-

Dimension(L*W*H):

-

3.2m*1.85m*2.2m

-

Function:

-

Sterilization

-

Heating way:

-

Steam Boiler

-

Application:

-

Food Products

-

Sterilizing Type:

-

Water Spary

-

Usage:

-

Extend Food Shelf Life

-

Material:

-

Stainless Steel SUS304

-

Design Temperature:

-

147 Degree Centigrade

-

Control Mode:

-

PLC

-

Medium:

-

Water and Steam

-

Package:

-

Wooden Case

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DTS

-

Voltage:

-

220V/380V/415V/440V(or customized)

-

Power:

-

20-50kw

-

Weight:

-

1280 KG

-

Dimension(L*W*H):

-

3.2m*1.85m*2.2m

-

Function:

-

Sterilization

-

Heating way:

-

Steam Boiler

-

Application:

-

Food Products

-

Sterilizing Type:

-

Water Spary

-

Usage:

-

Extend Food Shelf Life

-

Material:

-

Stainless Steel SUS304

-

Design Temperature:

-

147 Degree Centigrade

-

Control Mode:

-

PLC

-

Medium:

-

Water and Steam

-

Package:

-

Wooden Case

Product Description

Short Description of Milk Retort Machine

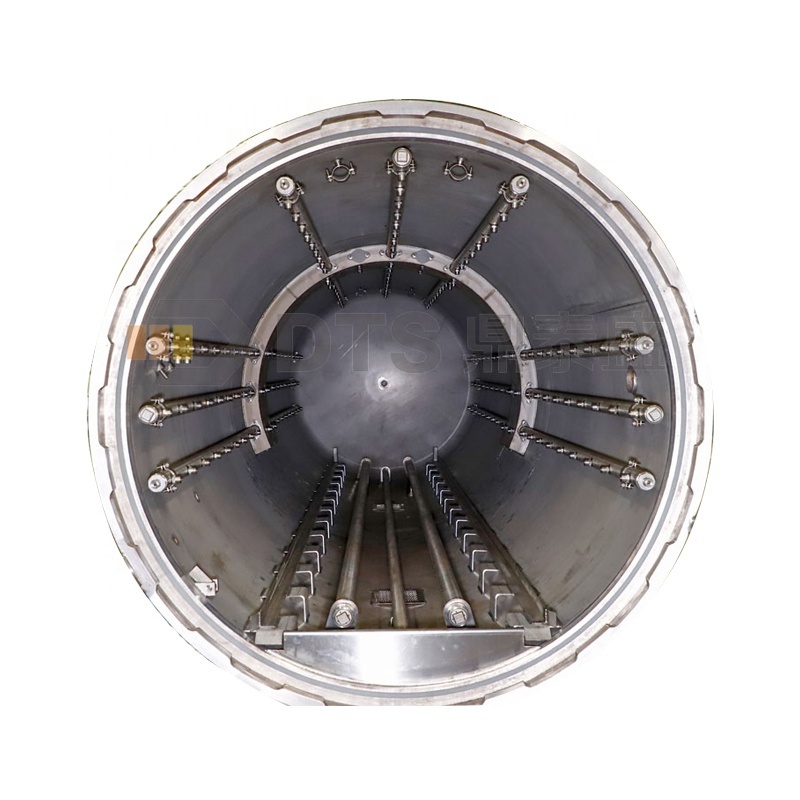

The water spray retort is the most commonly used retort for milk sterilization. According to different product and sterilization process requirements, customer can choose three types of cascading spray, side spray and water spray retort. The cascading spray retort is suitable for hard Pouch Food products, the side spray retort is suitable for soft packaged foods, and the water spray retort can handle almost all types of container foods. The process water is sprayed onto the product through the water pump and the nozzles distributed in the retort to achieve the purpose of sterilization. Accurate temperature and pressure control can be suitable for a variety of food and beverage.

Advantage of Milk Retort Machine

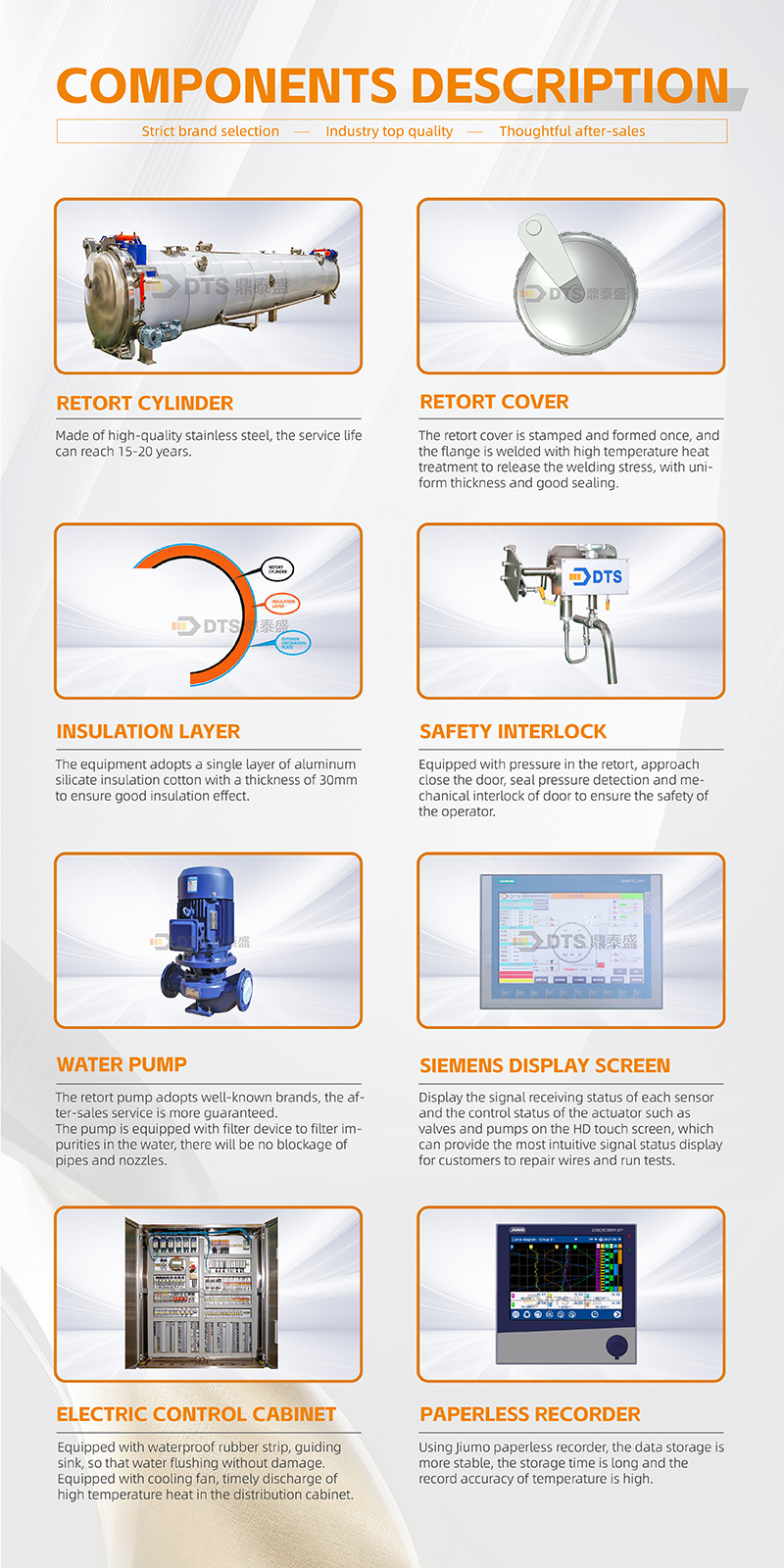

1, Accurate temperature control, excellent heat distribution.

2, Perfect pressure control, suitable for a variety of packaging forms.

3, Compliant with CE, EAC, ASME, DOSH, MOM, KEA, SABER, CRN, CSA certificate.

4, Energy saving and environmental protection.

5, Fast and uniform sterilization processing.

6, Indirect aseptic cooling by spiral tube heat exchanger. The possibility of the product being cooled by the sterilizationprocess water during the cooling process is avoided.

7, Save water without using water treatment chemicals significantly reduce heating and cooling costs per process.

8, Irregularly shaped containers can be firmly held in place during shaking (when equipped with rotation function).

9, Thermal process control monitoring distillation system, retort monitoring host, basket tracking system can be equipped as required.

10, DTS sterilizer adopts high-quality accessories at home and abroad with high sensitivity, high control accuracy and good running condition. With high, medium and low different configurations of the sterilizer, we can provide the required sterilization equipment for different customer groups.

Advantage of Milk Retort Machine

1, Accurate temperature control, excellent heat distribution.

2, Perfect pressure control, suitable for a variety of packaging forms.

3, Compliant with CE, EAC, ASME, DOSH, MOM, KEA, SABER, CRN, CSA certificate.

4, Energy saving and environmental protection.

5, Fast and uniform sterilization processing.

6, Indirect aseptic cooling by spiral tube heat exchanger. The possibility of the product being cooled by the sterilizationprocess water during the cooling process is avoided.

7, Save water without using water treatment chemicals significantly reduce heating and cooling costs per process.

8, Irregularly shaped containers can be firmly held in place during shaking (when equipped with rotation function).

9, Thermal process control monitoring distillation system, retort monitoring host, basket tracking system can be equipped as required.

10, DTS sterilizer adopts high-quality accessories at home and abroad with high sensitivity, high control accuracy and good running condition. With high, medium and low different configurations of the sterilizer, we can provide the required sterilization equipment for different customer groups.

| Model | Diameter(mm) | Body Length(mm) | Volume(m³) | Length(mm) | Width(mm) | Height(mm) |

Basket size (L*W*Hmm) |

| P-1003 | 1000 | 2400 | 2.12 | 4000 | 1850 | 2220 | 745×665×631 |

| P-1204 | 1200 | 3600 | 4.47 | 4400 | 2350 | 2400 | 860×800×775 |

| P-1403 | 1400 | 3000 | 5.24 | 3900 | 2450 | 2700 | 920×920×915 |

| P-1505 | 1500 | 5300 | 10.12 | 6300 | 2600 | 3250 | 1000×1000×975 |

| P-1806 | 1800 | 7800 | 21.12 | 8700 | 3100 | 3500 | 1220×1220×1170 |

Detailed Images

Product Application

Packaging & Shipping

Why Choose Us

FAQ

A: FOB, CFR & CIF optional; It’s mainly depend on client’s requirement; Accepted payment types: T/T, L/C;

Q: What can you buy from us?

A: Water spray retort, immersion retort, steam retort, steam and air retort, rotary retort, lab retort, tunnel pasteurizing and cooling machine

Q: Do you have any warranty about your equipment?

A: One year warranty. Frankly speaking, the quality of our machines is very stable. The machine will be tested many times before leaving the factory to ensure that when the machine arrives at your address, it is in the best condition. We also put in a set of spare parts that are prepared in advance from the machine's toolbox. During use, if you need any spare parts or have any questions, you can call us at any time.

Q: What’s the lead time after placing order?

A: Usually it takes about 2-3 months after we received your deposit. However, it would depend on our production line schedule (the timing clients place order) and the complication of the item.

Q: What is the cost of shipping?

A: Shipping cost is based on the following elements:

1.Type of container needed

2. Number of packages

3. Gross weight

4. Package volume

5. Destination port

Q: What is the installation and training methods?

A: Our engineer will inspect and guide the installation of the equipment and the connection of the pipeline on site until the equipment is running smoothly.

Q: What can you buy from us?

A: Water spray retort, immersion retort, steam retort, steam and air retort, rotary retort, lab retort, tunnel pasteurizing and cooling machine

Q: Do you have any warranty about your equipment?

A: One year warranty. Frankly speaking, the quality of our machines is very stable. The machine will be tested many times before leaving the factory to ensure that when the machine arrives at your address, it is in the best condition. We also put in a set of spare parts that are prepared in advance from the machine's toolbox. During use, if you need any spare parts or have any questions, you can call us at any time.

Q: What’s the lead time after placing order?

A: Usually it takes about 2-3 months after we received your deposit. However, it would depend on our production line schedule (the timing clients place order) and the complication of the item.

Q: What is the cost of shipping?

A: Shipping cost is based on the following elements:

1.Type of container needed

2. Number of packages

3. Gross weight

4. Package volume

5. Destination port

Q: What is the installation and training methods?

A: Our engineer will inspect and guide the installation of the equipment and the connection of the pipeline on site until the equipment is running smoothly.

Hot Searches