- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QY

-

Product name:

-

Alumina ceramic nozzle

-

Electrical Insulation:

-

Excellent

-

Density:

-

3.65 - 3.90 g/cm3

-

Max. Working Temp:

-

1,500 - 1,800 °C

-

Color:

-

white and ivory

-

Certificate:

-

ISO9001-2008/CE

-

Thermal Shock Resistance:

-

180 - 220 T(°C)

-

Compressive Strength:

-

2,000 - 2,500 Mpa

-

Flexural Strength:

-

280 - 300 Mpa

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Hunan, China

-

Model Number:

-

QY23101701

-

Brand Name:

-

QY

-

Product name:

-

Alumina ceramic nozzle

-

Electrical Insulation:

-

Excellent

-

Density:

-

3.65 - 3.90 g/cm3

-

Max. Working Temp:

-

1,500 - 1,800 °C

-

Color:

-

white and ivory

-

Certificate:

-

ISO9001-2008/CE

-

Thermal Shock Resistance:

-

180 - 220 T(°C)

-

Compressive Strength:

-

2,000 - 2,500 Mpa

-

Flexural Strength:

-

280 - 300 Mpa

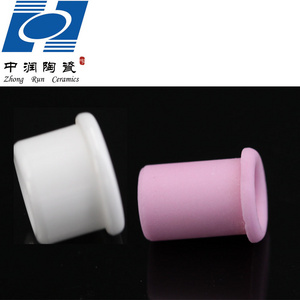

High-frequency porcelain 95% al2o3 alumina welding ceramic nozzle for sandblasting

Product Description

| Test item | alumina | |||

| index | unit | AL997 | AL99 | AL95 |

| Principal component content | N/A | 99.70% | 99% | 95% |

| Color | N/A | ivory white | ivory yellow | White |

| Gas permeability | N/A | airtight | airtight | airtight |

| density | g/cm3 | 3.9 | 3.8 | 3.7 |

| hardness | Moh's hardness | 9 | 9 | 8.8 |

| Water Absorption | N/A | ≤0.2 | ≤0.2 | ≤0.2 |

| Bending strength (20°C) | Mpa | 375 | 340 | 304 |

| Compressive Strength (20°C) | Mpa | 2300 | 2210 | 1910 |

| Coefficient of thermal expansion (25°C to 800° C) | 10X6/° C | 7.6 | 7.6 | 7.6 |

| Insulation strength (5mm thickness) | AC-kv/mm | 10 | 10 | 10 |

| Dielectric loss 25°C lMHz | N/A | v0.0001 | 0.0006 | 0.0004 |

| dielectric constant 25°C MHz | N/A | 9.8 | 9.5 | 9.2 |

| Volume resistivity (20°C) (300°C) (500 °C) | Ω.cm3 | >1014 | >1014 | >1014 |

| 2X1012 | 4X10" | 2X10" | ||

| N/A | N/A | N/A | ||

| Long-term service temperature | ℃ | 1700 | 1600 | 1400 |

| Thermal conductivity (25° C) | W/m/K | 35 | 34 | 20 |

Material Properties

- Excellent electrical insulation properties

- High hardness and mechanical strength

- Wear and abrasion resistant

- High thermal conductivity and thermal shock resistance

- Low density

- Resistant to strong acid and alkali attack at high temperatures

- Transparent to microwave radio frequencies

- High compressive and dielectric strength

- Very specific thermal conductive and thermal expansion rates

Related product

Certifications

Hot Searches