- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5500*1250*2200mm

-

Weight:

-

300 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v

-

Power:

-

5.2KW

-

Applicable Industries:

-

Food & Beverage Shops

-

After-sales Service Provided:

-

Online support

-

Key Selling Points:

-

High Productivity

-

Name:

-

automatic potato chips making machine price

-

Explosion area:

-

4300*500mm

-

Motor Power:

-

5.2KW

-

Temperature control:

-

80-300℃

-

Material:

-

Stainless steel

-

Application:

-

potato, sweet potato, cassava and so on

-

Certification:

-

CE ISO

Quick Details

-

Machinery Capacity:

-

420L

-

Brand Name:

-

WANGTEER

-

Year:

-

2022

-

Dimension(L*W*H):

-

5500*1250*2200mm

-

Weight:

-

300 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v

-

Power:

-

5.2KW

-

Applicable Industries:

-

Food & Beverage Shops

-

After-sales Service Provided:

-

Online support

-

Key Selling Points:

-

High Productivity

-

Name:

-

automatic potato chips making machine price

-

Explosion area:

-

4300*500mm

-

Motor Power:

-

5.2KW

-

Temperature control:

-

80-300℃

-

Material:

-

Stainless steel

-

Application:

-

potato, sweet potato, cassava and so on

-

Certification:

-

CE ISO

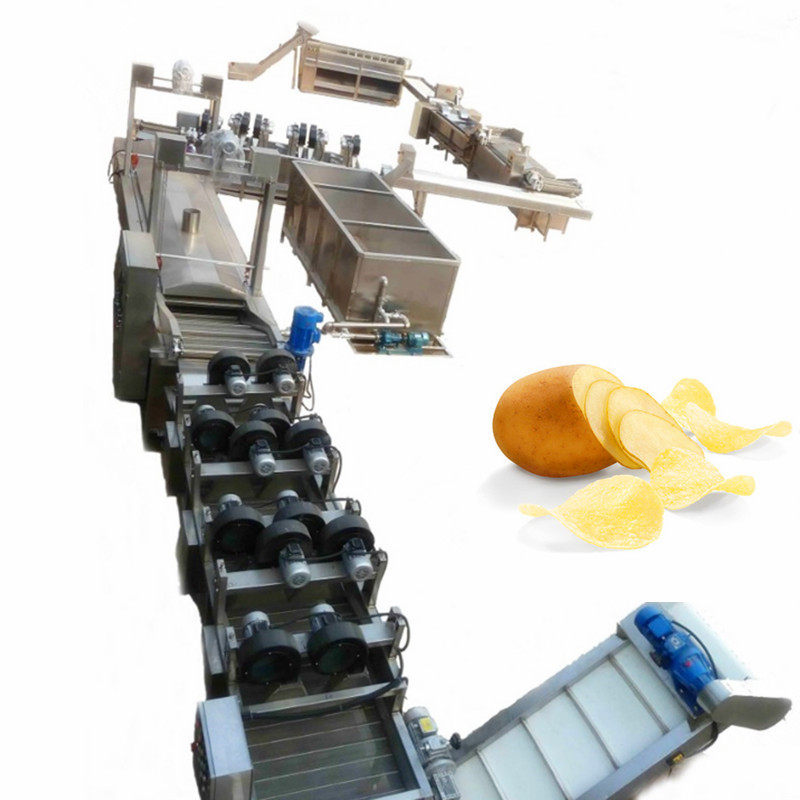

French Fry Production Line Industrial Fryer Automatic Potato Chip Making Machine Price

What is Features of our automatic potato chips making machine price?

Factory direct electric heating frying machine Energy-saving frying machine Explosion product color uniform equipment features:

1. Stainless steel production.

2. Automatic separation of oil and water, high degree of automation, can achieve continuous work, automatic temperature control, original spray automatic cooling system.

3. There is an oil level observation window, automatic slag removal, and frequency conversion to adjust the frying speed and time.

4. Safe and convenient operation, stable and reliable performance, long equipment life.

5. The frying effect is good, the taste is pure, and the taste is delicious.

The advantages of automatic oil-water separation fryer:

1.The advanced oil-water integrated technology overcomes the defects of the conventional frying machines and automatically filters them to keep the frying oil clean and keeps the frying products consistent. It not only improves product quality, but also extends the shelf life. A higher added value.

2.Advanced mechanical configuration and control can maintain a good working condition, not only improve the output but also make the product quality stable, color, smell and taste

3.The automatic filtration of the machine can greatly prolong the service life of the frying oil without frequent oil changes. The oil consumed during the frying process is equivalent to the oil absorbed by the product, and the fuel efficiency is not questionable.

4. The advanced and efficient heating system avoids energy waste to a greater extent and saves a lot of energy expenses

5.The realization of the continuous work of this machine has improved the working efficiency of the unit, effectively reduced the unit cost, and also extremely helped the labor expenditure and management expenditure.

What is Specifications of our automatic potato chips making machine price?

Fried potato chips production line Fully automatic frying production line Main technical parameters of French fries mesh belt frying production line: 150-200kg/h frozen French fries processing example:

|

Product name |

Voltage |

Power |

Dimensions |

|

Hoist |

380V |

0.75KW |

2000*800*2000mm |

|

Cleaning peeling machine |

380V |

4.75KW |

1800*900*1500mm |

|

Picking machine |

380V |

0.75KW |

3000*900*900mm |

|

Potato chips fries machine |

380V |

1.5KW |

950*800*950mm |

|

Rinsing machine |

380V |

5KW |

3500*1600*900mm |

|

Bleaching machine |

380V |

20KW |

3500*1600*950mm |

|

Drying water remover |

380V |

8KW |

3000*1000*1200mm |

|

Fried line |

380V |

48KW |

3500*1000*2000mm |

|

Vibration oiling machine |

380V |

1.5KW |

1500*1000*1300mm |

|

Freezing machine |

380V |

30KW |

6500*2800*2100mm |

|

Packing Machine |

380V |

2.2KW |

1410*750*900mm |

What is automatic potato chips making machine price Application?

Electric heating oil frying line, automatic temperature control, automatic circulation filtration system, automatic slag removal system, automatic replenishment system, automatic lifting control, adjustable frying time, variable frequency speed control, convenient cleaning and maintenance, of the main material is stainless steel 304.

Product Photos

1. Equipment introduction

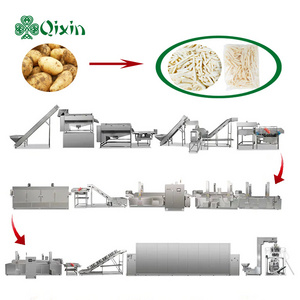

Fully automatic production of fully automatic fry fries production line is the essence of domestic counterpart products, simplifying and concentrating the production process, and designing and developing with reference to customer feedback information. It has the advantages of high degree of automation, saving labor, improving work efficiency, and improving profit margins for customers.

2 . Flow chart

1, cleaning peeling machine 2, loading machine 3, fries machine 4, blanching machine 5, wind drain 6, frying machine 7, wind blow 8, packaging machine

3 . C omplete equipment introduction

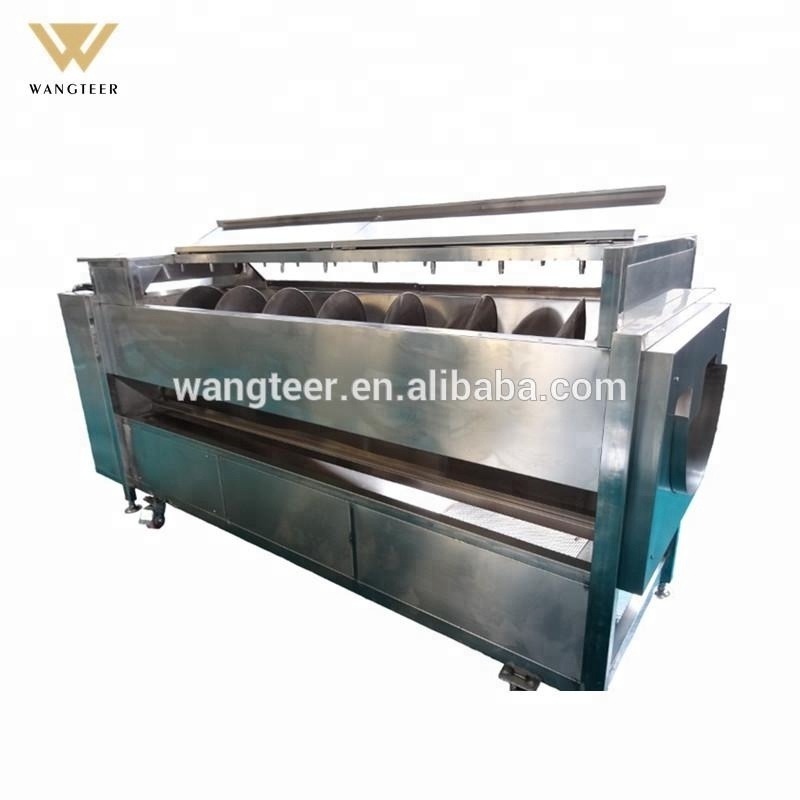

1. Cleaning and peeling machine: The brush-type cleaning and peeling machine can be used to complete cleaning and peeling at the same time. High efficiency and low loss

2. cutting machine: cutting strip size 6mm-10mm adjustable.

3. Bleaching machine: rinse and protect the cut potato chips.

4. Dehydrator: Dewatering with centrifugal force. Dehydration before frying can greatly shorten the frying time and improve the taste of potato chips.

5. Oil-water mixed frying machine: Due to the different proportions of water and oil, the water is on the lower side, and the oil is heated to fry the potato chips in the upper layer. The resulting residue is directly precipitated in the water. The oil does not emit black smoke, which greatly prolongs the service life of the oil and makes the cost significantly larger. decline. Oil temperature control, thus ensuring the quality and taste of potato chips. After the work is completed, the water is released and the residue flows out with the water.

6. Deoiler: Centrifugal deoiler will deoil the freshly-fried potato chips (bars), which overcomes the high oil content and greasy mouthfeel of chips. Improves the taste of chips (bars).

7. Seasoning machine: After the deoiled potato chips (bars) are seasoned and seasoned, the structure is simple and practical. The barrel body is made of stainless steel octagonal design, which can make the food materials to be processed and the required seasoning powder mix evenly in a short time Automatic discharge, easy cleaning and disinfection without dead ends.

8. Nitrogen filling packaging machine: When packing, nitrogen is filled in the packaging bag to effectively prevent the potato chips (bars) from being crushed and extend the shelf life. Inflate, pack, and code one time.

Cleaning peeling--slicing, cutting machine--blowing machine---dewatering machine--fried machine--deoiler--flavoring Machine ---- Vacuum Packing Machine

Hot Sale

After-sale service

The company has professionals who install and commission the equipment sold on site. Ensure that the equipment is processed according to customer requirements and that the factory is a brand new product. Our company implements a one-year free warranty on the products it sells and a lifetime commitment to service. And equipped with a number of technical and comprehensive engineering and technical personnel to solve technical problems for customers. The company provides installation, commissioning, maintenance, training, technical consulting and other pre-sale services. Choose WANGTEER machinery, so that you no worries! Our sales philosophy: quality-oriented, customer first, first products, after the market, business integrity! WANGTEER machinery works hand in hand with you! Look forward to working with you!

Company View

WANGTEER Machinery Co., Ltd. specializes in the production of frying equipment, cleaning equipment, drying equipment, potato chips and fries production lines, vacuum frying equipment for fruit and vegetable chips, and potato chip production line. It has R&D team and experimental base for customers. The shaped products are processed and customized.

The company is a research and development, manufacturing, production, sales, with comprehensive strength of the company, ranking first in sales in the industry. WANGTEER Machinery Co., Ltd., in line with the principle of good faith management, with "good faith, quality first, service protection" as its purpose. Do a one-stop installation, commissioning and after-sales service to eliminate the user's worries. Do the product first, then do the market, the customer's praise is the best advertisement! WANGTEER works hand in hand with you to adhere to the principle of "seeking development through science and technology and surviving through quality". With the goal of "pay close attention to quality and credibility, and strengthen management and strive to be first class", we will forge ahead and strive to open up the market. The company faces the future, will be high-quality products, perfect after-sales service, business reputation is not bad faith, and look forward to new and old friends to discuss cooperation, create brilliant tomorrow! !

Trade Terms:

1. Payment: T/T, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before deliverying.

2. Delivery Time: 30 days

3. MOQ: 1pcs

4. Package Informations: Standard export wooden case.

Why Choose us?

1. We are China Professional Food Machines Manufacturer.

2. Alibaba Assessed 6 years Gold Supplier.

3. Inspected by the Inspection Institution of Bureau Veritas Certification.

4. 100% QC inspection Before Shipment.

5. Best Quality & Best Service with Competitive price.

6.The company adheres to the core values of "Science leads development, integrity determines the future", adheres to the "people-oriented, daring to innovate" development path, constantly draws on advanced technologies and processes at home and abroad, promotes innovation and development "quality first, service first".

7.For corporate philosophy and dedication to provide excellent users Products, the most satisfactory service; We sincerely look forward to working with domestic and foreign manufacturers and customers in good faith cooperation, mutual exchanges, coordinated development, mutual and win-win situation, create brilliant.

How to Contact Us?

Send your Inquiry Details in the Below,Click"Here"Now!You Can Get More