- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

7000*800*1650mm

-

Power (kW):

-

25kw

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Model:

-

RSL ADYFY

-

Motor Powder:

-

25KW

-

Overall size:

-

7000*800*1650mm

-

Feed speed:

-

12-20m/min

-

Panel Thickness:

-

10-60mm

-

Belt thickness:

-

0.4-3mm

-

Min length of panel:

-

>=150mm

-

Min width of panel:

-

>=50mm

-

Working air pressure:

-

0.6-0.8Mpa

-

Weight:

-

2500kg

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Rensolin

-

Voltage:

-

220/380V/415V

-

Dimension(L*W*H):

-

7000*800*1650mm

-

Power (kW):

-

25kw

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Model:

-

RSL ADYFY

-

Motor Powder:

-

25KW

-

Overall size:

-

7000*800*1650mm

-

Feed speed:

-

12-20m/min

-

Panel Thickness:

-

10-60mm

-

Belt thickness:

-

0.4-3mm

-

Min length of panel:

-

>=150mm

-

Min width of panel:

-

>=50mm

-

Working air pressure:

-

0.6-0.8Mpa

-

Weight:

-

2500kg

full automatic edge banding machine

Products Description

Main Functions

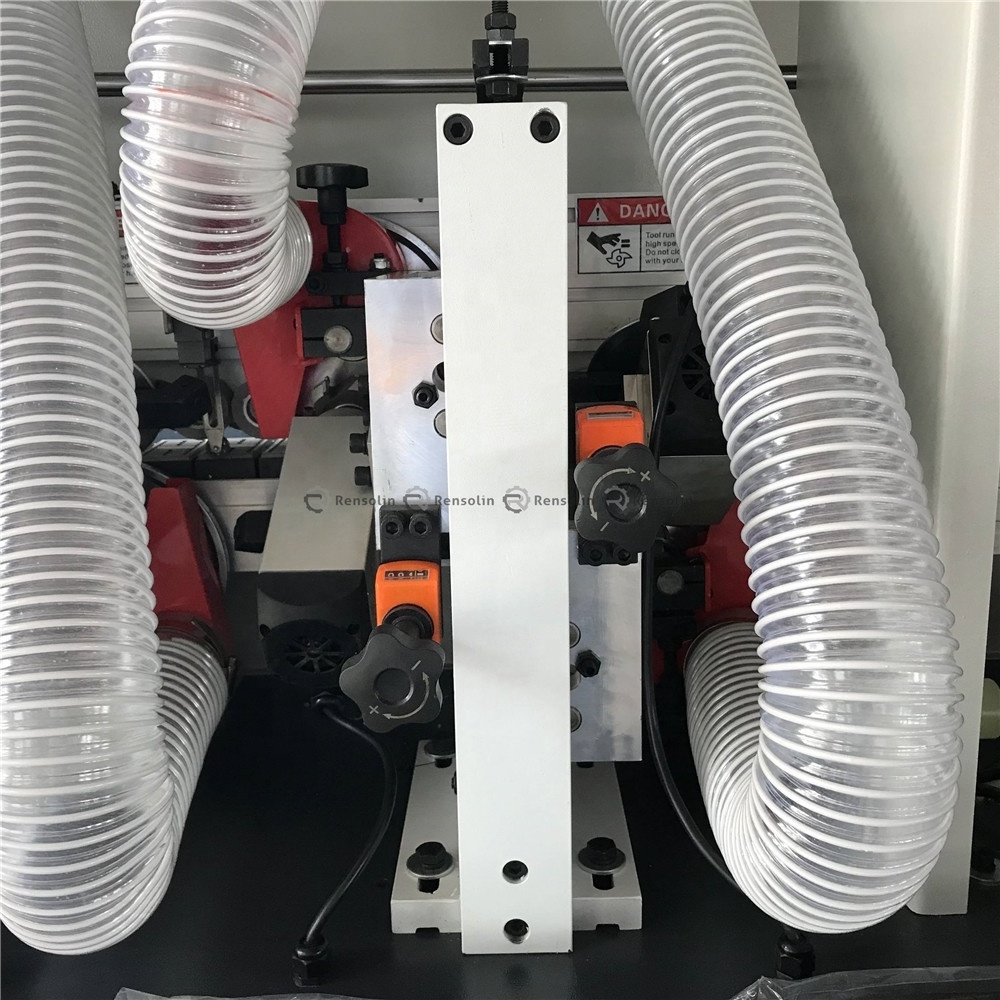

Step1:Pre-milling

modify the ripple marks caused by cutting

board saw, and the burr is modified again to achieve better sealing effect.

Step2: Glue and Pressing

Using the spiral structure of glue feeding , through the processing center of the one-time forming of the glue pot heating sol,so

that the plate uniformly coated with glue and the adhesive force is more firm.

that the plate uniformly coated with glue and the adhesive force is more firm.

Step3: End Cutting

High matching German technology are adopted, through precise direct selling guide rail movement, adopt automatic tracking by mold and high frequency high click quick cutting structure, ensure smooth cutting surface, quick and light cutting drive.

Step4: Rough Trimming

It is recommended to use the rough repair function when sealing the edge belt with a thickness of more than 1.5mm. If sealing PVC,acrylic and wood veneer, it must be roughened to reduce the cutting force and wear of the finishing tool.

Step5: Fine Trimming

Fine repair is divided into two kinds of flat repair and oblique repair, oblique repair in the sealing surface of high brightness edge strip ,will not seal edge strip surface dark mark.

Step6: Corner Rounding

Adopt high speed motor, can make the end face of plate more smooth.

Step7: Scraping

It is used to eliminate the ripple marks caused by the cutting process of non-linear motion of trimming, make the plate more

smooth and neat, and adjust the size of arc Angle at the same time, make the sealing effect more delicate.

smooth and neat, and adjust the size of arc Angle at the same time, make the sealing effect more delicate.

Step8: Slotting

①Vertical Slotting Function lt can be used for grooving the back plate, and it is more convenient to finish the edge sealing and

grooving at onetime.

grooving at onetime.

②Horizontal slotting function Can be used for wardrobe side board, floor and other directslotting, can also be used for door aluminum edge slotting,reduce cutting board saw or end milling machine process.

Use cotton polishing wheel to clean the finished plate, remove the excess glue, and make the sealing section more smooth by polishing.

Product Paramenters

|

Edge Banding Machine

|

RSL 450ADYFK

|

|

Motor Power

|

25KW

|

|

Overall size

|

7000*800*1650mm

|

|

Feed speed

|

15-23m/min

|

|

Panel thickness

|

10-60mm

|

|

Belt thickness

|

0.4-3mm

|

|

Min. length of panel

|

≥150mm

|

|

Min. width of panel

|

≥50mm

|

|

Working air pressure

|

0.6-0.8 Mpa

|

|

Weight

|

2500KG

|

product advantages

Display Screen

The electronic screen displays the temperature control meter, and the numbers are displayed more clearly. There are three button below, namely the power switch, the lighting switch, and the auxiliary switch. The right side is equipped with an emergency stop

to protect personal safety and stop machine operations in time.

to protect personal safety and stop machine operations in time.

Laser cut body

Laser cutting steel plate base Laser cutting steel plate base, making the welded body strong and not deformed, increasing the stability of the machine.

Imported motor, multi- choices

Use imported motor and high quality electronic parts.Product seriation, multi-choice for customers.

Related product

Products Effect Display

Service

PRE-SALE SERVICES:

1. Introduce and Provide detailed consultation of the machine.

2. Strict quality control system, warranty period: 2 years.

3. Provide custom- -made service, offering good suggest and design idea to customer.

4. Welcome to visit our factory.

SERVICES DURING SALES:

1. Fast delivery and 100% QC Inspection before shipment.

2. Install and debug the machine well in our factory.

3. Provide safety package and shipping to clients.

AFTER-SALE SERVICES:

1. Carefully train frst-line operators' operation knowledge.

2. Engineers available to service machinery overseas timely.

3. Our sales team and senior engineer are ready for service for you in every 7x24h.

FAQ

Q1: How to install?

A1: We adjusted machines well before we deliver. When customers receive them, you can work with them directly.

For sliding table saw you just need install sliding table on machine body by 4 bolts.

For sliding table saw you just need install sliding table on machine body by 4 bolts.

Q2: How to ensure the safety?

A2: There have the overload and over heat protection, it ensure working people safety.

Q3: How long the table saw machine can be used?

Q3: How long the table saw machine can be used?

A3: It depends how you use your table saw, if use it in good maintenance, at least8-10 years.

Q4: What is the Delivery time?

Q4: What is the Delivery time?

A4. Our delivery time is around 3-15 days. Before the machine arrive at the port, the shippingcompany will call you.

Q5: Where is your company located?

Q5: Where is your company located?

A5: We are Chinese company. Our city is in Qingdao. It is the biggest seaport in the north ofChina.

Q6: Are there any requirements for the dealer?

Q6: Are there any requirements for the dealer?

A6: There is no special conditions to be our dealer. You buy from us and sell to your customers. We introduce customers to you.

Hot Searches