- Product Details

- {{item.text}}

Quick Details

-

Power:

-

300kw

-

Weight (KG):

-

400

-

Effective coating width:

-

500mm (customizable)

-

Substrate winding speed:

-

0.5~3m/min

Quick Details

-

Machine Type:

-

Coating Equipment, Coating Equipment

-

Place of Origin:

-

China

-

Voltage:

-

380V±10%

-

Power:

-

300kw

-

Weight (KG):

-

400

-

Effective coating width:

-

500mm (customizable)

-

Substrate winding speed:

-

0.5~3m/min

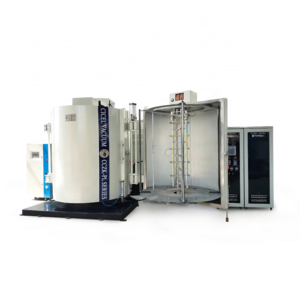

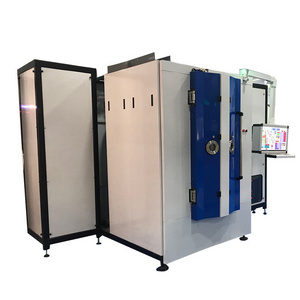

Magnetron Sputtering and Evaporation Vacuum Metallizing Coating Machine

Application scope

The Vacuum Metallizing Machine is a horizontal circular multifunctional magnetron sputtering coating equipment, which is used for plating metal film on aluminum foil polyester cloth or plastic film.

Features

1. The winding system is composed of the winding device of the base material. The winding device of the base material is composed of the unwinding device, the winding device and some reverse rolls, as well as the wallboard installed with these rolls; The system uses Mitsubishi servo control to drive the unwinding of the base material, the synchronous rotation of the winding and the coating roll, and uses Mitsubishi full-automatic tension system control technology to automatically control and feedback the film tension.

2. The whole machine is controlled by industrial touch screen and Japanese Omron PLC, which can be controlled manually, semi-automatically or fully automatically. The main control cabinet controls vacuum pumping, coating, process gas and other operations. The whole machine has the function of sound-light alarm for water cut, power cut and insufficient water flow.

3. Interlock protection function is provided between all pumps and valves to protect the vacuum pump and alarm in case of misoperation.

4. The coating chamber is equipped with a cryogenic system to speed up the vacuum pumping efficiency.

5. All water pipes and wires shall be laid in the trunking in order and not exposed. All welds are uniform and neat, the vacuum chamber is painted outside, and the overall appearance is beautiful and generous.

6. The vacuum room is equipped with lighting, online video monitoring and other devices for easy observation.

Specification

|

Film condition |

Coiling condition |

Polyester or PET plastic film,Aluminized |

|

Effective coating width |

500mm (customizable) |

|

|

Maximum winding diameter |

Φ300mm (customizable) |

|

|

Inner diameter of winding mandrel |

3inch(subject to actual conditions) |

|

|

Substrate winding speed |

0.5~3m/min |

|

|

Substrate winding tension |

0~300N |

|

|

Vacuum conditions

|

Ultimate pressure (no load, clean) |

≤8×10-4Pa |

|

Vacuum recovery time (no load, clean) |

10Pa~8×10-3Pa≤20min |

|

|

Magnetron sputtering cathode power supply |

20KW6 DC power supplies |

|

|

Resistance evaporation system |

Power 18KW(subject to actual design) |

|

|

Vacuum control system |

Digital display vacuum gauge 2 sets |

|

|

Charging control system |

Flowmeter valve 2 sets |

|

|

Film uniformity |

≤±5% |

|

|

Water consumption |

60m3/h (18℃~30℃) |

|

|

Maximum power consumption |

300KW (380V±10%, 50h, 3-phase 5-wire system)

|

|

Product Image