- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SPC

-

Model Number:

-

SPC-1006

-

Type:

-

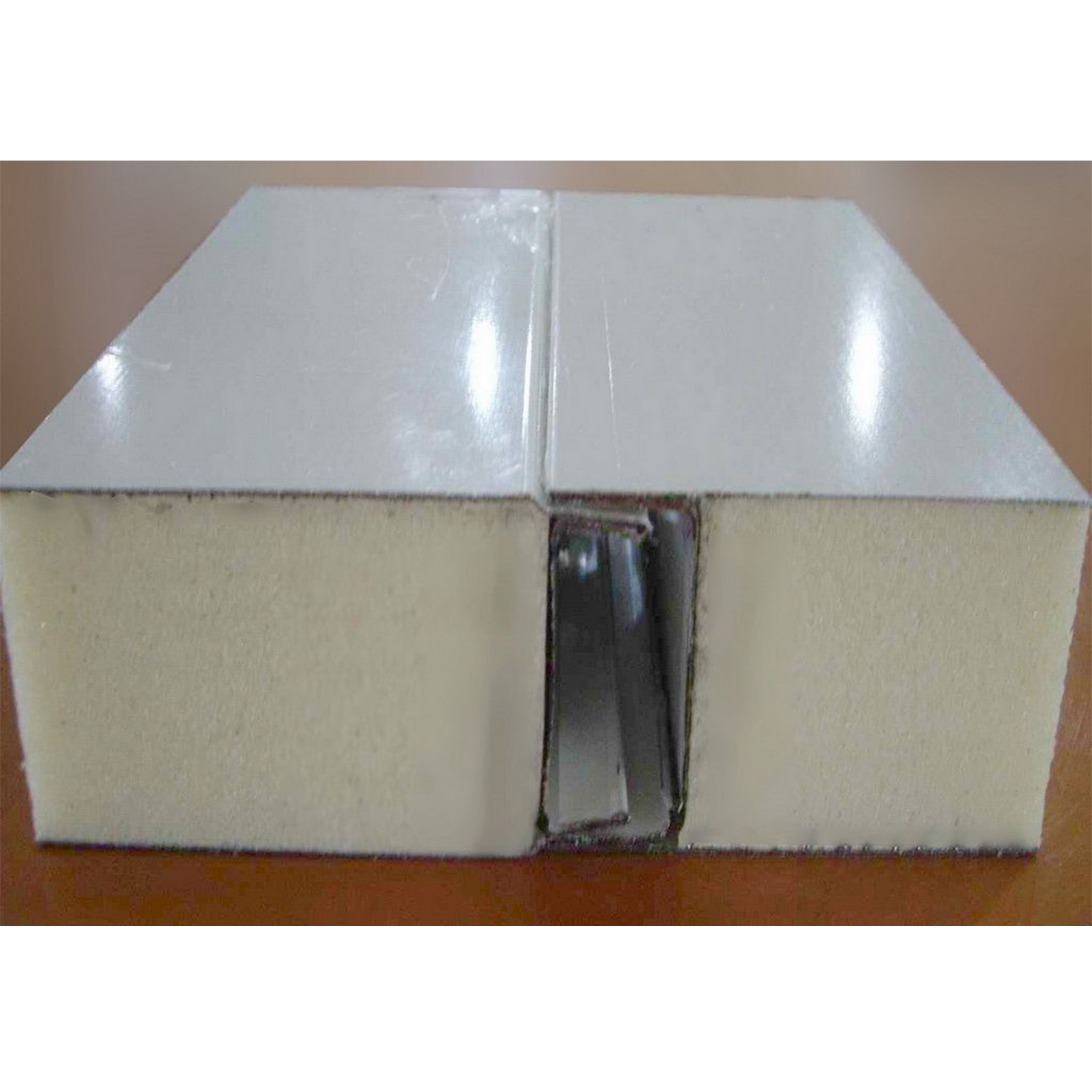

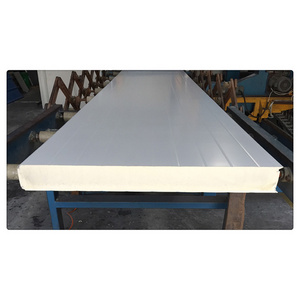

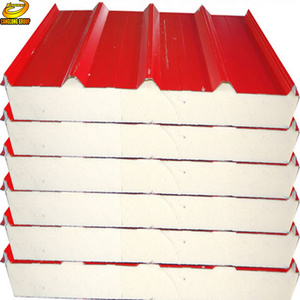

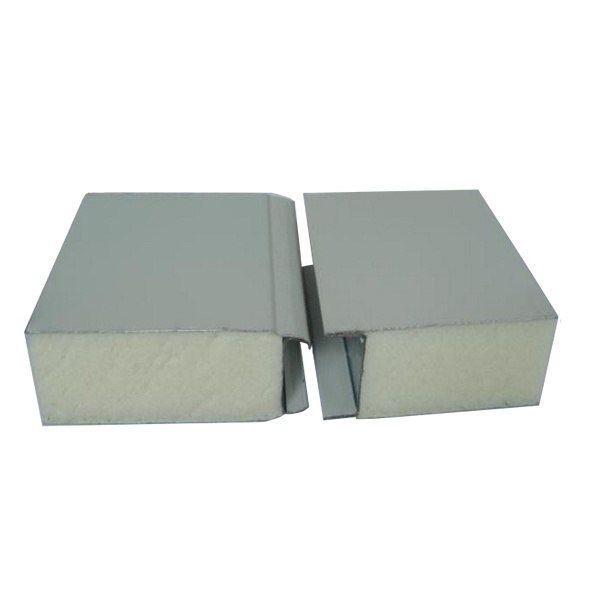

SPC-1006, sandwich panel material

-

Product name:

-

polyurethane

-

usage:

-

coldroom panel making

-

raw material:

-

polyol+isocyanate

-

package:

-

drum

-

Solid content:

-

100%

-

Proportion:

-

two components, 1:1 mix

-

Method:

-

spray

-

Color:

-

white gray or customized

-

Dosage:

-

0.7-2.5kg/sqm

Quick Details

-

CAS No.:

-

51852-81-4

-

Other Names:

-

Polyurethane Foam

-

MF:

-

(C10H8N2O2.C6H14O3)x

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SPC

-

Model Number:

-

SPC-1006

-

Type:

-

SPC-1006, sandwich panel material

-

Product name:

-

polyurethane

-

usage:

-

coldroom panel making

-

raw material:

-

polyol+isocyanate

-

package:

-

drum

-

Solid content:

-

100%

-

Proportion:

-

two components, 1:1 mix

-

Method:

-

spray

-

Color:

-

white gray or customized

-

Dosage:

-

0.7-2.5kg/sqm

|

SPECIFICATION OF PU POLYURETHANE RIGID FOAM

|

|

|

||

|

density:

|

KG/M³

|

≥42.9

|

||

|

heat conductivity coefficient:

|

W/M·K

|

≤0.02

|

||

|

moisture permeance factor

|

NG/PA.M.S

|

≤3.34

|

||

|

water absorption

|

G/100M²

|

≤0.5

|

||

|

closed porosity

|

%

|

≤97

|

||

|

compressive strength

|

KPA

|

≥220

|

||

|

flexure strength

|

KN/M²

|

≥2450

|

||

|

oxygen index

|

|

≥28

|

||

|

Combustion rating

|

|

B

|

||

|

Flame prevalence

|

|

≯15

|

||

|

Vertical burning method

|

burning time

|

≤7.96

|

||

|

|

combustion flame height

|

≤15

|

||

|

Stability

|

|

≤1%

|

||

|

The reaction time can adjust according to the requirements of the user.

|

|

|

||

FIRST AID FOR EYES & SKIN

|

polyol

|

220 kg per iron drum

|

|

|

isocyanate

|

250 kg per iron drum

|

|

|

one set

|

470 kg=220kg A+250kg B

|

|

|

One 20' container

|

40 sets/80 drums/18.8 tons

|

|

|

Moistureproof, ventilation, sealed storage, shelf life of 6 months.

|

|

|

We manufacture polyurethane pu foam ( blend polyol / mdi isocyanate )raw material ,polyurethane adhesive, including both one component polyurethane foam and two component polyurethane foam.

We have a group of material engineers who have great experience in special pu raw material research. Our products get excellent market all over the world.

At present my company's products also have low pressure polyurethane foaming machine,high pressure polyurethane foam injection machine, polyurethane sealing strip casting machine,polyurethane foam elastomer casting machine,pu foam car seat production line, pu foaming wall insulation board production line, pu foam tile sandwich panel production line and other pu foaming automatic production lines, all kinds of Polyurethane related foam machinery.

Our Team

We have professional team of mechanical engineer, chemical engineer, process engineer, etc, all of them have more than 10 years experience in PU foam filed. Also, we have special sales team, they are young but hard-working and experienced. We can meet any your requirements of the PU foam product, pu mold and PU foam machines.

R&D Team

Best Team

High Quality

Our Service

1. Professional and patient consulting service to help you find the suitable solution.

2.Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3.Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4.Free training in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5.Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6.For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7.For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that .

8.We give an accessory box for free.

9.We offer development solutions for raw material formulations.

10.If you need to visit the factory, we will arrange for personnel to pick up the airport.

Visitors and Exhibitions

We participated in many exhibitions of polyurethane raw materials, polyurethane foam products and polyurethane PU foam machines. Our products left a very good impression to everyone at the show, some customers even placed orders on the spot.

Certificate

1.Are you factory or trading company?

We are professional factory in PU industry with more than 10 years experience with many experienced chemical engineers can provide your any solutions of polyurethane foam need.

2.Where is your factory ?

Our Factory is located in Wuxi city, Jiangsu Province.

3.How can i get your factory?

By air: You can take a plan to WUXI airport from China, if you fly from Korea ,Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us.

By Train: You can stop at WUXI station, Not WUXI EAST station.

4.Do you provide pick-up service?

Yes, of course. If you are in Wuxi airport or station, we can arrange a special car to pick you up directly to our factory.

5.What kind of polyurethane foam do you have?

We have two kinds PU foam, polyurethane foam and polyurea foam. Polyurethane foam can be divided into flexible foam and rigid foam or open cell foam and closed cell foam.

6.What is the application of your PU expanding foam?

Polyurethane soft foam can make pu mat, pu car seat and headsets, pu pillow, pu stress ball and toy, pu earplugs, 3D leather wall panel and other customized products made from pu flexible foam. PU rigid foam can be used to produce pu trowel, pu crown molding, pu tire, pu bed sets, pu mirror frames and so on. We also sell integral skin raw material to make armrest, seat cushions and medical accessories.

In addition to the above, polyurethane foam can be also used to spray and cast for fireproof, waterproof, insulated, soundproof.

7.Does your polyurethane foam material have certificate?

Yes, we have certificate of liquid polyurethane foam.

8.What is the packaging of your polyurethane foam?

Polyol is 200-220 kg/barrel and Isocyanate is 250 kg/barrel. One set is 470 kg=220kg A+250kg B, one 20' container loads 40 sets/80 drums/18.8 tons.

9.What is your minimum order quantity of your foam material?

Our moq of PU raw material is one barrel.

10.Which kind of foam machine does this polyurethane foam suit for?

Spraying foam is suitable for our polyurethane foam spray machine. We also have polyurethane foam making machine and elastomer casting machine which can be used to produce any kinds of pu products and pu elastomer products.

11.Payment Term?

Normally we accept TT or L/C.

12.How to buy your PU foam material?

A: Firstly let us know your requirements or application.

B:Secondly We quote according to your requirements or our suggestions.

C:Thirdly customer confirms the PI and places deposit for formal order.

D:Fourthly We arrange the production.