The machine has a large power reserve, full electronic control, full hydraulic power drive, proportional control, three-track walking, and is equipped with automatic steering and automatic leveling control system. It can complete the vibration, paving, extrusion and other technological processes of cement concrete structures at one time.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

97kw

-

Dimension(L*W*H):

-

6800*2700*3100

-

Weight:

-

14000 kg

-

Maximum side paving height:

-

1300mm

-

Maximum paving width:

-

2000mm

-

Paving speed:

-

0~15m/min

-

Travel speed:

-

0~35m/min

-

Engine model:

-

YCF36125-T482 (Yuchai)

-

Rated power/speed:

-

92kW/2400r/min

-

Diesel tank capacity:

-

320L

-

Climbing capacity:

-

≥ 25%

-

Vibrating rod interface:

-

6

-

Vibrating rod frequency:

-

0~200Hz

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

new curber

-

Power:

-

97kw

-

Dimension(L*W*H):

-

6800*2700*3100

-

Weight:

-

14000 kg

-

Maximum side paving height:

-

1300mm

-

Maximum paving width:

-

2000mm

-

Paving speed:

-

0~15m/min

-

Travel speed:

-

0~35m/min

-

Engine model:

-

YCF36125-T482 (Yuchai)

-

Rated power/speed:

-

92kW/2400r/min

-

Diesel tank capacity:

-

320L

-

Climbing capacity:

-

≥ 25%

-

Vibrating rod interface:

-

6

-

Vibrating rod frequency:

-

0~200Hz

Product Overview

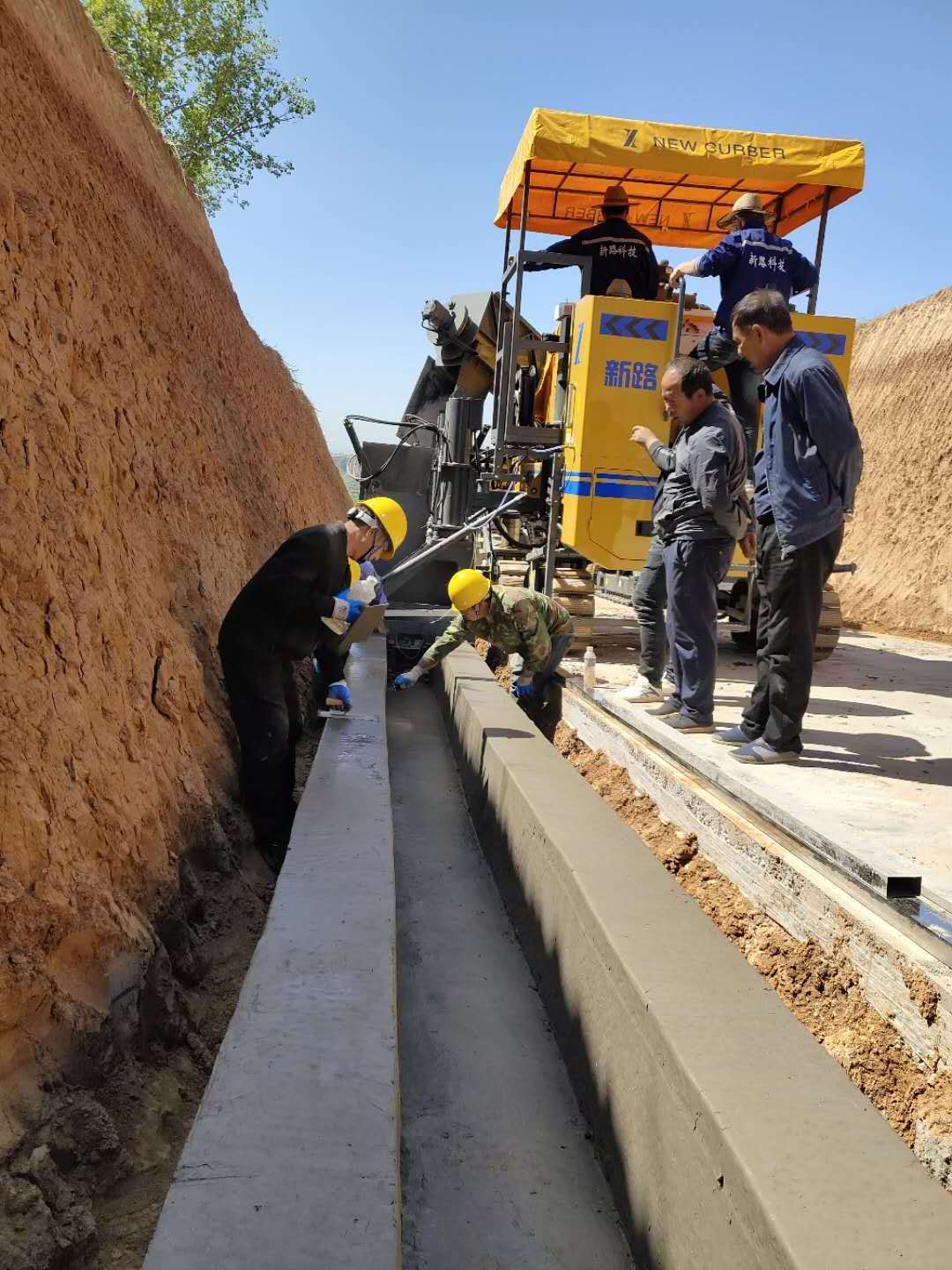

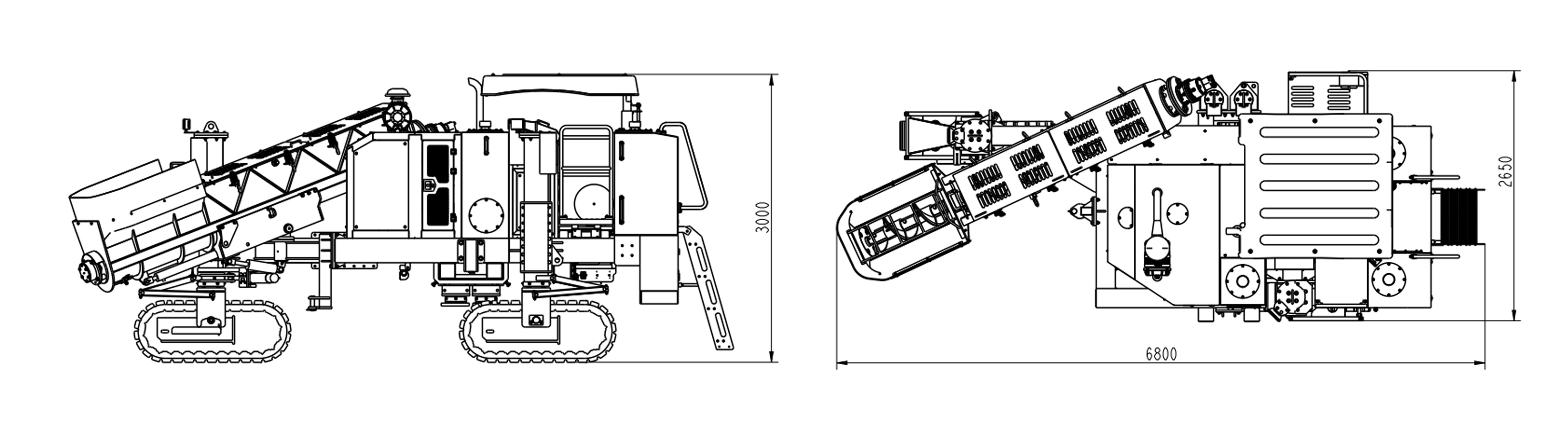

NC1300S concrete slip form paver

NC1300S concrete slip form paver One machine is multi-purpose and can realize various mold configuration modes. It is widely used in the construction fields of road drainage ditches, drainage channels, curbs, shoulder stones, concrete guardrails, cement concrete structures, farmland water conservancy ditches, etc., replacing the traditional process and significantly improving the construction quality and speed of cement concrete structures.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Item

|

Data

|

|

|

1

|

Basic performance parameters

|

Maximum side paving height

|

1300mm

|

|

|

|

|

Maximum paving width

|

2000mm

|

|

|

|

|

Paving speed

|

0~15m/min

|

|

|

|

|

Travel speed

|

0~35m/min

|

|

|

2

|

Powertrain

|

Engine model

|

YCF36125-T482 (Yuchai)

|

|

|

|

|

Rated power/speed

|

92kW/2200r/min

|

|

|

|

|

Diesel tank capacity

|

360L

|

|

|

3

|

Walking system

|

Three-track (front one and rear two), hydraulic independent drive, proportional control two-speed motor, planetary gear reducer

|

|

|

|

|

|

Track width

|

300mm

|

|

|

|

|

Track length

|

1600mm

|

|

|

|

|

Climbing capacity

|

≥ 25%

|

|

|

4

|

Outrigger steering lifting device

|

The front track steering device is equipped with displacement sensor for precise proportional control; Outrigger lifting hydraulic

proportional control |

|

|

|

|

|

Minimum turning radius

|

4200mm

|

|

|

|

|

Outrigger hydraulic lifting stroke

|

915mm

|

|

|

|

|

Outrigger mechanical adjustment stroke

|

280mm

|

|

|

5

|

Hydraulic system

|

Load sensitive dual-pump hydraulic system, proportional control walking, outrigger turning and lifting, vibrating rod and auger

feeding |

|

|

|

6

|

Electrical control system

|

Configure two longitudinal slope sensors, one transverse slope sensor and one steering sensor; Electronic automatic control is

adopted for longitudinal slope, cross slope and steering |

|

|

|

7

|

Auger conveyor

|

Twister speed

|

0~80r/min

|

|

|

|

|

The size of the auger feeding device is 3700mm long, and the blade diameter is 340mm

|

|

|

|

8

|

Vibrating compaction system

|

Hydraulic vibrator interface

|

6

|

|

|

|

|

Vibrating rod frequency

|

0~200Hz

|

|

|

9

|

High-pressure flushing device

|

Hydraulic driven high pressure ceramic plunger pump

|

|

|

|

|

|

water tank capacity

|

360L

|

|

|

10

|

Mold and mold fixture

|

Hydraulic horizontal stroke of mold fixture

|

1000mm

|

|

|

|

|

Hydraulic vertical stroke of mold fixture (double oil cylinder)

|

360mm

|

|

|

|

|

Mechanical vertical stroke of mold fixture

|

240mm

|

|

|

11

|

Overall dimension and weight (transportation status)

|

Transport dimension (long × wide × High)

|

6800×2650×3000mm

|

|

|

11

|

|

Machine weight

|

14000Kg

|

|

Our Advantages

Performance characteristics

1. One machine can be used for multiple purposes. By replacing various molds and accurately adjusting and controlling the vehicle status, the precise slipform paving of road drainage ditches, drain channels, curbs, shoulder stones, concrete guardrails and farmland water conservancy ditches can be achieved.

2. Three-track walking, hydraulic independent drive, proportional control two-speed motor, planetary gear reducer, to ensure paving stability and improve the quality of slipform paving; The front track steering device is equipped with a displacement sensor for accurate steering.

3. Powerful engine; The hydraulic system adopts load sensitive variable control to supply oil according to the actual load size and speed, with low fuel consumption, energy saving and environmental protection.

4. Humanized design of the operating platform, human-computer interactive control screen and clear graphical identification symbols make the operation of the paver simple and easy; It is equipped with Internet of Things platform, construction management and monitoring system, and optional remote control device.

5. The steering lifting adopts hydraulic proportional control, and is equipped with two longitudinal slope sensors, one transverse slope sensor and one steering sensor to improve the response speed and stability of the equipment, ensure accurate linear control, and realize overlay paving.

6. According to the working conditions, the left paving and middle paving can be realized; The mould fixing device adopts hydraulic horizontal and vertical two-way adjustment, which can quickly replace various moulds.

7. The inclination and expansion of the auger feeding device adopt hydraulic adjustment, which is easy to operate and suitable for various working conditions; Large storage space can realize the secondary mixing of cement concrete.

Successful Project

SIMILAR PRODUCTS

ABOUT US

Company profile

Xuzhou Xinlu Intelligent Technology Co., Ltd. was established in 2019, and was awarded "National High-tech Enterprise" in 2022, which was supported by the Ministry of Communications of China as a key enterprise in the transportation industry.

The company has passed I S O 9 0 0 1 quality management system and I S O 1 8 0 0 1 occupational health and safety management system certification. The Construction Specification for Slip-form Paving of Multifunctional Curb Structures, which was formulated in the lead, was issued by China Construction Machinery Industry Association in April 2022 and implemented in July of the same year.

Now the company covers an area of 72,000 square meters, with standardized industrial workshops, R&D test centers and comprehensive office and living quarters, and has the production organization and processing and manufacturing capacity of more than 300 sets of high-end cement concrete slipform pavers per year.

The main products are N C series lateral cement concrete slipform paver, N R series middle cement coagulation slipform paver soil and supporting equipment, The products sell well all over the country, showing high attendance rate in high altitude, high temperature and high humidity areas, and are widely praised by customers. We will continue to uphold the core values of "Honesty is gold, service is heart", carry forward the enterprise spirit of "Innovation drives the future and strives to forge a new road".

Company's Gate

Office Building

In The Foot Of The Car

Workshop 1

Warehouse

Workshop 2

Our Team

All Hands

After-sales Service Department

Production workers

Technology Department

Sales Department

R&D Department

SALES AND SERVICE NETWORK

FAQ

Q1.What is the main function of slipform paver?

Ans.: It is applied to the construction fields of road drainage ditch, drain channel, curbstone, shoulder stone, concrete

guardrail, cement concrete structure, farmland water conservancy channel, etc。

Q2.What is the warranty of our machine?

Ans.:

Product warranty form

1. Engine: 12 months, according to the three-guarantee instructions of the engine manufacturer;

2. Electrical control system: six months; Except for force damage

3. Electrical circuit: six months

4. Electrical accessories (battery light horn, etc.): one month

5. Hydraulic pump: 12 months

6. Hydraulic valve block: 12 months

7. Hydraulic motor: 12 months

8. Hydraulic pipeline: six months

9. Water pump: six months

10. Structural parts: 12 months

Vulnerable parts:

1. Stir up the bearing: three months, normal wear is not subject to three guarantees

2. Mixing blade: three months

3. Vibrating rod: six months

Q3.What is the lead time and shipping method?

Ans.:Usually the lead time is 7-15 days, and we send the machine by sea.

Q4.What kinds of payment terms do we accept?

Ans.:T/T or L/C at sight...

Ans.: It is applied to the construction fields of road drainage ditch, drain channel, curbstone, shoulder stone, concrete

guardrail, cement concrete structure, farmland water conservancy channel, etc。

Q2.What is the warranty of our machine?

Ans.:

Product warranty form

1. Engine: 12 months, according to the three-guarantee instructions of the engine manufacturer;

2. Electrical control system: six months; Except for force damage

3. Electrical circuit: six months

4. Electrical accessories (battery light horn, etc.): one month

5. Hydraulic pump: 12 months

6. Hydraulic valve block: 12 months

7. Hydraulic motor: 12 months

8. Hydraulic pipeline: six months

9. Water pump: six months

10. Structural parts: 12 months

Vulnerable parts:

1. Stir up the bearing: three months, normal wear is not subject to three guarantees

2. Mixing blade: three months

3. Vibrating rod: six months

Q3.What is the lead time and shipping method?

Ans.:Usually the lead time is 7-15 days, and we send the machine by sea.

Q4.What kinds of payment terms do we accept?

Ans.:T/T or L/C at sight...

Hot Searches