- Product Details

- {{item.text}}

Quick Details

-

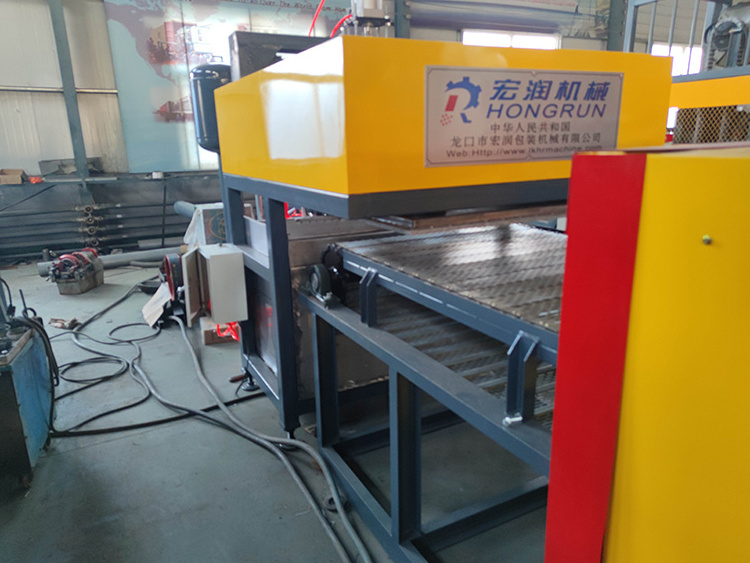

Voltage:

-

380V

-

Power:

-

200-240KW

-

Dimension(L*W*H):

-

30*4*4M

-

Weight:

-

3000 kg

-

Warranty:

-

ONE YEAR

-

Product name:

-

waste paper coffee tray machine for coffee shop with two trays

-

large Capacity:

-

1000pcs/hr~12000pcs/hr

-

Shaping machine type:

-

Roller type

-

Finished Products:

-

coffee tray

-

Raw material:

-

Recycled waste paper

-

Fuel type:

-

Natural gas/Diesel oil/Coal

-

Certification:

-

CE/ISO

-

Drying system:

-

multi-layer mental

-

Controller:

-

PLC+TOUCH screen

-

Feature:

-

Degradable pulp tray

Quick Details

-

Production Capacity:

-

8000-12000pcs/hr

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hongrun

-

Voltage:

-

380V

-

Power:

-

200-240KW

-

Dimension(L*W*H):

-

30*4*4M

-

Weight:

-

3000 kg

-

Warranty:

-

ONE YEAR

-

Product name:

-

waste paper coffee tray machine for coffee shop with two trays

-

large Capacity:

-

1000pcs/hr~12000pcs/hr

-

Shaping machine type:

-

Roller type

-

Finished Products:

-

coffee tray

-

Raw material:

-

Recycled waste paper

-

Fuel type:

-

Natural gas/Diesel oil/Coal

-

Certification:

-

CE/ISO

-

Drying system:

-

multi-layer mental

-

Controller:

-

PLC+TOUCH screen

-

Feature:

-

Degradable pulp tray

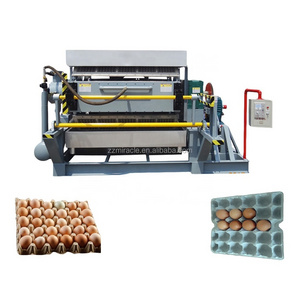

Automatic Factory Supply Egg Trays Cup Carrier Molded Pulp Degradable Packaging for Coffee Tray Production Line with High Effiency

From craftsmanship to quality, from function to performance, whatever you want, or you have never thought of it, he can satisfy it

ADVANTAGES OF PULP MOLDING PACKAGING Factory Supply Egg Trays Cup Carrier Molded Pulp Degradable Packaging for Coffee Tray Production Line with High Effiency

Convenient Model Take Away Cardboard Carrier Handle Reusable Go Coffee 2 4 6 Cups Tray Holder Making Machine For Hot Drink

1 Easy to recycle, known as "green packaging"

2. The government has taken measures to encourage companies to use recycled and easily decomposable packaging materials.

3. In international trade, it is recognized and accepted by merchants from various countries.

4. Exemption from import and export packaging pollution treatment tax.

5. It has low price and good waterproof, shockproof and anti-static properties.

6. It has good breathability and moisture evaporation.

7. Configurable in multiple colors.

8. Can be stacked relative to each other to reduce storage space.

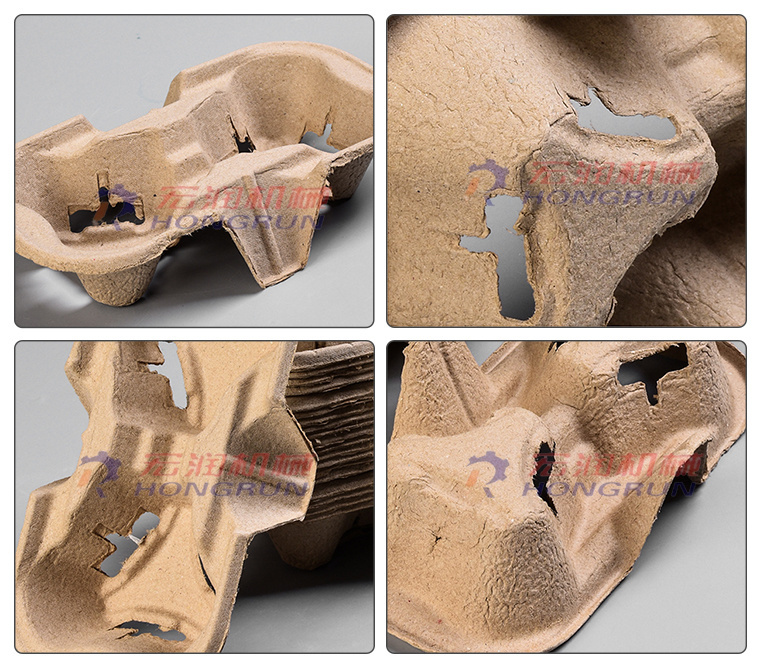

Factory Supply Egg Trays Cup Carrier Molded Pulp Degradable Packaging for Coffee Tray Production Line with High Effiency is mainly for coffee tray shop and it can solve the problems of take-away coffee to pack coffee cup in it, which can help consumer.

For choosing suitable one, here're some models for your review below. While the raw material is recyclable and reusable to make full use of the allocate resources, such as the waste newspaper, waste paper and used carton box, which can save cost and friendly environment. MAKE THE RECYCLABLE WASTE INTO MONEY to SAVE COST

For the machine spare parts, we can show you more details and please be assured that the quality is with high performance.

Click the following contact information

Product Type : Paper products processing machinery

Processing Type : Pulp Molding Machine

Product Name: Factory Supply Egg Trays Cup Carrier Molded Pulp Degradable Packaging for Coffee Tray Production Line with High Effiency

Capacity:

1000-6000 pcs/hr

Approval:

CE/ISO

Warranty:

12 Monthes

Rotary:

12 Faces

Forming Platen Size:

2350 x 420 mm

Matches with 6-layer dryer, energy efficient and conserve energy

Large capacity Automatic waste paper coffee tray machine for coffee shop with two trays with automatic hot pressing and intelligent conveying stacking technology.

Mainly applied for egg tray, egg carton, fruit tray, cup carrier, bottle tray etc.

Convenient Model Automatic disposable biodegradable paper pulp 2 4 compartment coffee paper cup carrier tray machine price with nice quality

There is paper pulp on the mold and in the process of heating, they're fallen from the mold.

Features for Factory Supply Egg Trays Cup Carrier Molded Pulp Degradable Packaging for Coffee Tray Production Line with High Effiency

1. Raw material: all waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get.

2. Automation: Fully-automatic control

3. Quality standard: CE

4. 100% environmentally production process.

5. Engineers available to service machinery overseas

The pulp molding machine divided into Four Part :

First: The pulping system

the main function of the entire production line is to pass our raw material waste paper through this system to make a certain concentration of pulp. using the feeder to pour the waste paper and water into the pulper to make the pulping , can save the labor cost , achieve the automation of the machine .

Compared to different materials

Pulp molded products are made from paper scraps and white pure wood pulp as raw materials. They are molded and adsorbed, then dried and shaped. They are easily degradable and 100% recyclable and environmentally friendly. And with its unique consistent geometric shape, it achieves excellent shockproof, anti-impact, anti-static, and non-corrosive effects. It has low price, no pollution to the environment, 100% recyclable, environmentally friendly, and excellent shockproof characteristics. Can replace EPS and PS foam products.

(recyclable raw materials)

Pulp molded products (i.e. paper trays) are a new type of environmentally friendly inner packaging product that replaces foam packaging. They have shock-proof protection and can be recycled and reused, complying with the EU Environmental Protection Directive.

Environmental protection requirements for product exports are a new generation of packaging products

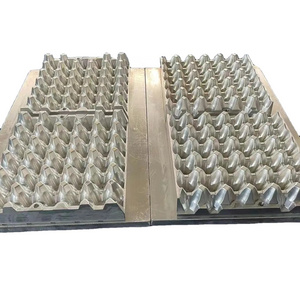

Second:The forming system

transfer the finished paper pulp into forming machine ,By the negative pressure to absorb the finished paper pulp and form

fruit/egg tray/paper products on the mold,transfer the wet paper products to the drying line.

Transfer the finished paper pulp into forming machine to make different paper products by the different mold .

Third:The Drying system

After the first step of our main molding system, we must carry out a one-time and thorough drying process for our molded wet fruit/ egg trays/wet products , use the coal , natural gas , diesel , LPG ,oil , or wood ..... as the fuel , it is up to your

choice .

Transfer the wet paper products to the drying line to dry . Use the big blower and small fan to make the hot air recycle running and discharge the moisture from wet products.

Fourth: Packing system

after drying, the fruit/egg trays/wet paper products can be directly packed or used after being compressed by the packing system.

After drying , the paper products need to be stacked , then need to be directly packed or used after being compressed by the packing system.

Automatic Factory Supply Egg Trays Cup Carrier Molded Pulp Degradable Packaging for Coffee Tray Production Line with High Effiency

New products Factory Supply Egg Trays Cup Carrier Molded Pulp Degradable Packaging for Coffee Tray Production Line with High Effiency

| Model | Capacity | Forming machine | Drying system | Workshop spcae | Rated power |

| HRZ-1500S | 1500pcs/hr | 3molds *4faces | Single-Layer Metal | 35m*10m*6m | 130KW |

| Rotary type | |||||

| HRZ-1500M | 1500pcs/hr | 3molds *4faces | 6 Layers | 25m*10m*6m | 120KW |

| Rotary type | Mental | ||||

| HRZ-2000S | 2000pcs/hr | 4molds *4faces | Single-Layer Metal | 40m*10m*6m | 165KW |

| Rotary type | |||||

| HRZ-2000M | 2000pcs/hr | 4molds *4faces | 6 Layers | 25m*10m*6m | 145KW |

| Rotary type | Mental | ||||

| HRZ-3000S | 3000pcs/hr | 3molds *8faces | Single-Layer Metal | 45m*10m*6m | 209KW |

| Rotary type | |||||

| HRZ-3000M | 3000pcs/hr | 3molds *8faces | 6 Layers | 30m*10m*6m | 189KW |

| Rotary type | Mental | ||||

| HRZ-4000S | 4000pcs/hr | 4molds *8faces | Single-Layer Metal | 55m*10m*6m | 239KW |

| Rotary type | |||||

| HRZ-4000M | 4000pcs/hr | 4molds *8faces | 6 Layers | 30m*10m*6m | 223KW |

| Rotary type | Mental | ||||

| HRZ-5000S | 5000pcs/hr | 5molds *8faces | Single-Layer Metal | 70m*15m*6m | 298KW |

| Rotary type | |||||

| HRZ-5000M | 5000pcs/hr | 5molds *8faces | 6 Layers | 35m*15m*6m | 273KW |

| Rotary type | Mental | ||||

| HRZ-6000S | 6000pcs/hr | 6molds *8faces | Single-Layer Metal | 80m*15m*6m | 365KW |

| Rotary type | |||||

| HRZ-6000M | 6000pcs/hr | 6molds *8faces | 6 Layers | 37m*15m*6m | 326KW |

| Rotary type | Mental | ||||

| HRD-8000M | 8000pcs/hr | 4*8 & 4*8 | 6 Layers | 40m*15m*8m | 368KW |

| Double-roller | Mental | ||||

| HRD-12000M | 12000pcs/hr | 5*8 & 5*8 | 6 Layers | 42m*15m*8m | 428KW |

| Double-roller | Mental |

Here are our egg tray machine Youtube Video for your reference.

1. https://youtu.be/w7RGvwMD_YM

6000pcs/hr egg tray machine for Peru customer

2. https://www.youtube.com/watch?v=0etQZo0CbEY 4000pcs/hr egg tray machine for pakistain

3. https://youtu.be/gwF4El_tA6Q 2000pcs/hr egg tray machine for our Iraq customer

Automatic Paper pulp cup holder tray of sugarcane pulp coffee cup holder paper take away drink carrier paper cup holder tray machine

Pre-sales services

* All information about our machine by email/phone will be replied ASAP

* We help customers to design the layout of the machine in workshop.

* according to the customers’ requirements and circumstance to make the best egg tray production line design .

* support factory to prepare.

In the sale of services

* we are in charge of installing,debugging and training

* technical guidance

* test the machine in the factory before the delivery

After-sales service

* one year guarantee for whole machine include the spare parts

* calling, network or door-to-door service

* use friendly English software, user manual and detailed Videos/CD

* engineers can be sent to the buyers' countries