- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

None

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AONUO

-

Model Number:

-

1148

-

Product Name:

-

Spray Polyurea Coatings For Storage Tank/chest/pipe Anti-corrosion

-

Solid content:

-

100%

-

Viscosity(25℃):

-

≤1000mPa.s

-

Part A Density(25℃):

-

A:1.080-1.160g/cm3

-

Part B Density(25℃):

-

B:1.030-1.100g/cm3

-

Theoretical Coating Amount(1mm):

-

1.05-1.10kg/m2

-

Volume Mixing Ratio:

-

A:B=1:1

-

Shelf Life:

-

1 year

-

Substrate:

-

Existing Finishes

-

Color:

-

Customized

Quick Details

-

CAS No.:

-

None

-

Other Names:

-

Spray Polyurea Waterproof Coating

-

MF:

-

None

-

EINECS No.:

-

None

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AONUO

-

Model Number:

-

1148

-

Product Name:

-

Spray Polyurea Coatings For Storage Tank/chest/pipe Anti-corrosion

-

Solid content:

-

100%

-

Viscosity(25℃):

-

≤1000mPa.s

-

Part A Density(25℃):

-

A:1.080-1.160g/cm3

-

Part B Density(25℃):

-

B:1.030-1.100g/cm3

-

Theoretical Coating Amount(1mm):

-

1.05-1.10kg/m2

-

Volume Mixing Ratio:

-

A:B=1:1

-

Shelf Life:

-

1 year

-

Substrate:

-

Existing Finishes

-

Color:

-

Customized

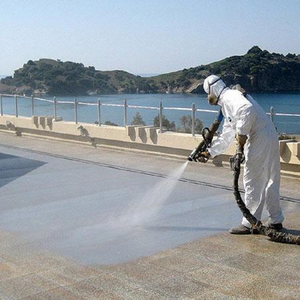

Polyurea Coatings For Storage Tank

Production Description

Product name:Chinese manufacturer Spray Polyurea Coatings For Storage Tank/chest/pipe Anti-corrosion

The coating system consists of amine-terminated polyether resin, amine chain extender and MDI prepolymer, belongs to spraying self-cured elastic polyurea, has high strength and high tearing resistance and endows the coating with high abrasion resistance.

Recommended Applications

Rubber liner pipelines, mining equipment, truck lining, washing rotary drums and cement mortar process equipment.

Product Characteristic &Physical Properties

|

Product Characteristic |

||||||

|

Solid Content |

100% |

Volume Mixing Ratio |

A: B = 1:1 |

|||

|

V iscos ity (25℃) |

≤1000mPa.s |

Shelf Life |

1 year |

|||

|

Density (25℃) |

A: 1.080-1.160 g/cm

3

|

Theoretical Coating Amount (Dry Film: 1mm Thickness) |

1.05-1.10kg/m 2 |

|||

|

Curing Characteristics |

||||||

|

Gelation Time |

10-40 seconds |

Curing Time |

24 hours |

|||

|

Touch Drying Time |

90-150 seconds |

Maximum Strength |

14 days |

|||

|

Physical Properties |

||||||

|

Tensile Strength |

≥18MPa |

Tearing Strength |

85KN/m |

|||

|

Elongation |

≥300% |

Abrasion Resistance |

≤100mg |

|||

|

Hardness |

90-98A |

Recommended Thickness |

2-10mm |

|||

* Drying time is temperature, humidity, and film thickness dependent.

* Coating equipment status determines the property of coating.

* A test sample is cured in a thermostat of 65-70℃ for 24 hours.