- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

Shandong, China

-

Application:

-

extreme environment, Industry

-

Grade:

-

Nickel Base Alloy

-

Ni (Min):

-

58%

-

Model Number:

-

Customized

-

Brand Name:

-

Zehao

-

Product name:

-

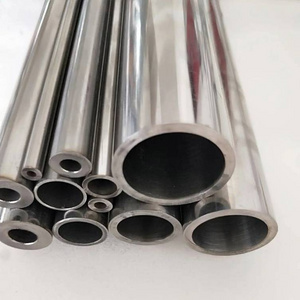

Nickel Alloy pipe

-

Shape:

-

Round.square.Rectangle

-

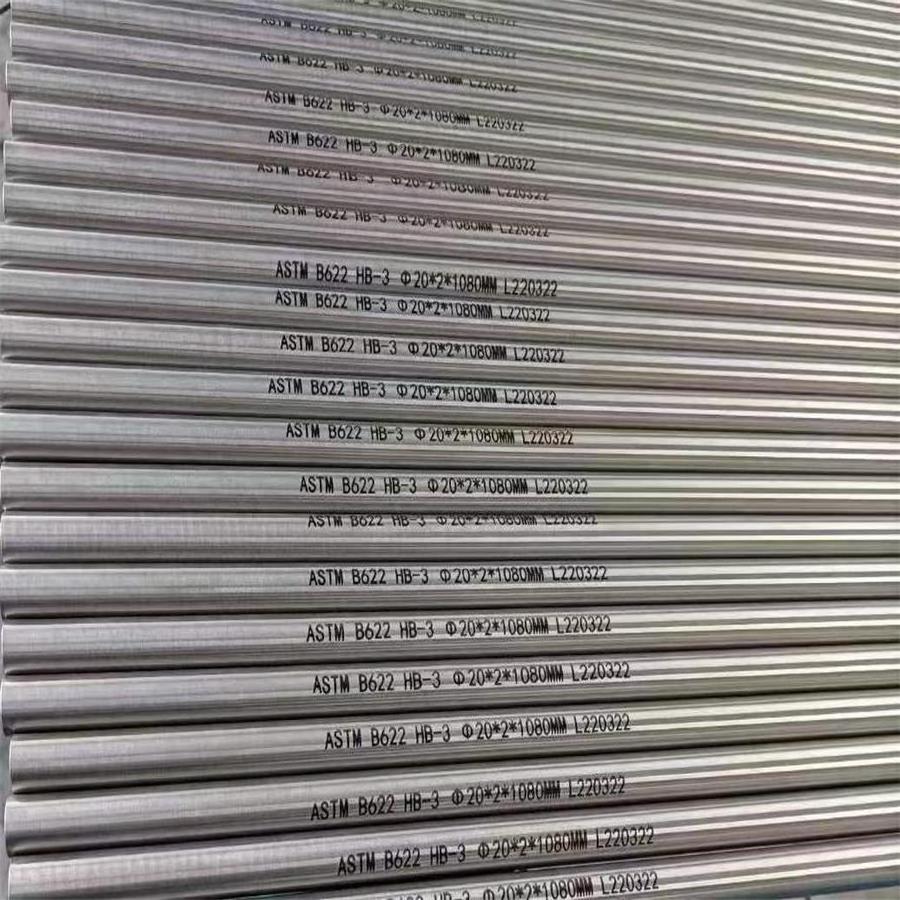

Standard:

-

ASTM ASME SUS JIS DIN

-

Surface:

-

Bright

-

Color:

-

Silver Gray

-

Keyword:

-

Nickel Alloy pipe

-

Payment term:

-

30%TT Advance + 70% Balance

-

Packing:

-

PVC+waterproof Paper+wooden Case

-

DELIVERY TIME:

-

7-20 Days

Quick Details

-

Resistance (μΩ.m):

-

1.03

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

600~650

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

Shandong, China

-

Application:

-

extreme environment, Industry

-

Grade:

-

Nickel Base Alloy

-

Ni (Min):

-

58%

-

Model Number:

-

Customized

-

Brand Name:

-

Zehao

-

Product name:

-

Nickel Alloy pipe

-

Shape:

-

Round.square.Rectangle

-

Standard:

-

ASTM ASME SUS JIS DIN

-

Surface:

-

Bright

-

Color:

-

Silver Gray

-

Keyword:

-

Nickel Alloy pipe

-

Payment term:

-

30%TT Advance + 70% Balance

-

Packing:

-

PVC+waterproof Paper+wooden Case

-

DELIVERY TIME:

-

7-20 Days

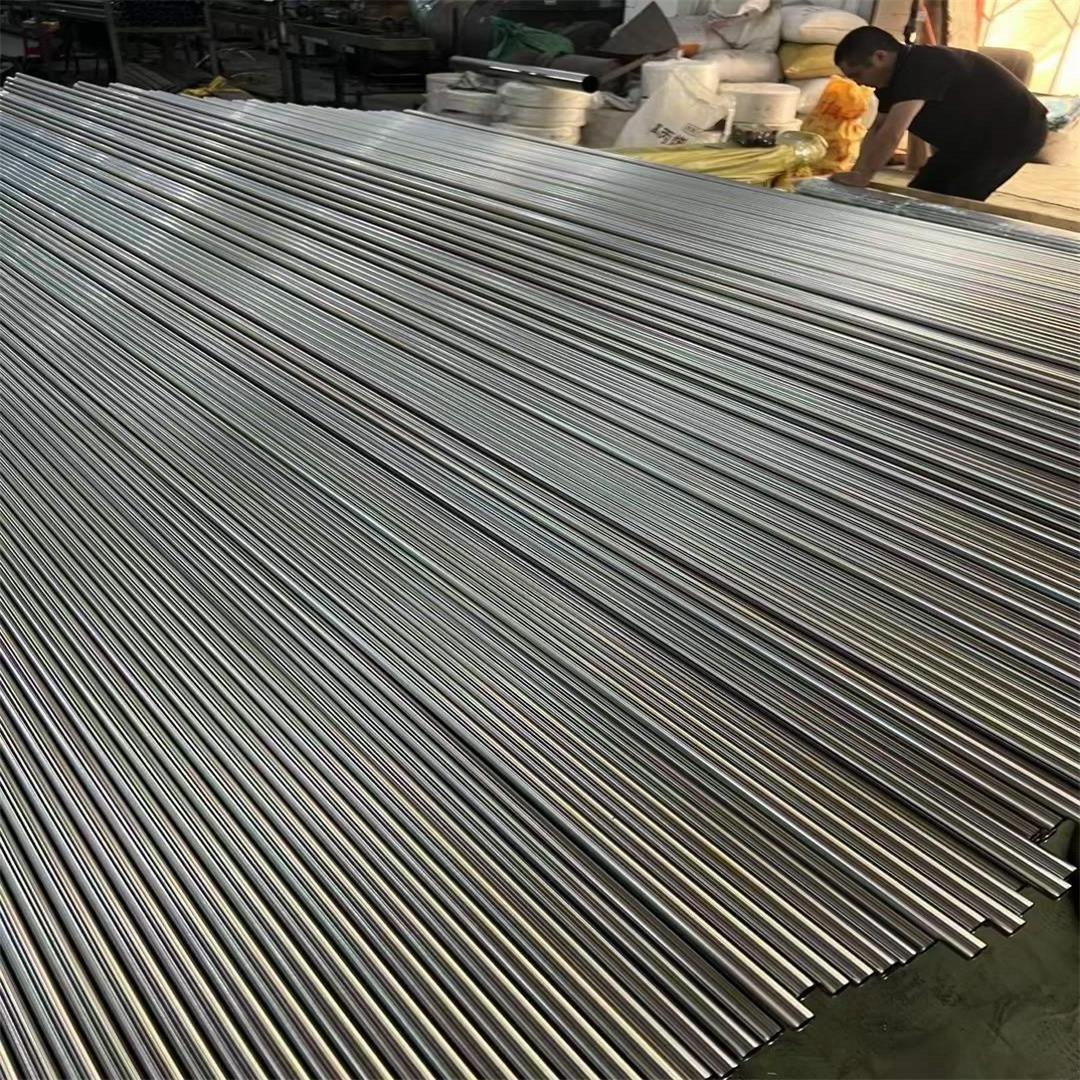

Product Description

Nickel-based alloy

r

efers to a class of alloys with high strength and certain antioxidant corrosion resistance at 650~1000℃. Subdivided according to the main main performance

They are nickel-based heat resistant alloy, nickel-based corrosion resistant alloy, nickel-based wear resistant alloy, nickel-based precision alloy and nickel-based shape memory alloy. According to the different matrix, superalloys are divided into:

Iron based superalloys, nickel based superalloys and cobalt based superalloys. Nickel-based superalloy is referred to as nickel-based alloy.

Specification

|

Nickel Alloy Pipe

|

|

|

|

Thickness

|

0.5mm-30mm as your request

|

|

|

Size

|

8mm-530mm as your request

|

|

|

Length

|

1 meters to 6 meters or as customer 's requirement

|

|

|

Material Classification

|

|

|

|

Monel Alloy

|

MONEL K-500, Monel400/2.4360, Monel 401.

|

|

|

Inconel Alloy

|

Inconel840 (S33400), Inconel 686 (2.4606-N06686), Inconel725 (NO7725), Inconel713C (2.4671), Inconel625 (2.4856), Inconel602ca

(N06625), Inconel601 (2.4851), Inconel600 (2.4816), Inconel 690 (2.4642), Inconel617 (N06617), InconelX-750 (750), Inconel804, Inconel718 (2.4668). |

|

|

Incoloy Alloy

|

Incoloy 800HT, Incoloy 890/1. 6569, Incoloy 810, Incoloy801, Incoloy 840/UNS S33400, Incoloy 20/UNS N08020, Incoloy 926/UNS

N08926/1.4529, Incoloy 901/UNS N09901/2. 4662, Incoloy330/UNS N08330/1. 488, Incoloy945/ (UNS N09945) , incoloy A-286 /(UNS S66286/1.4980) , Incoloy 825/2.4858, Incoloy 925/UNS N09925, Incoloy 800H/800HT/800AT. |

|

|

High Temperature Alloy

|

GH3308, GH3304, GH4090, GH738, GH3030, GH159 (GH6159) , GH3039, GH3044, GH3536, GH5188, GH1131, GH4141, GH2026, GH738, GH80A,

GH4090, GH3600, GH2132, GH3625, GH3128, GH4145, GH4169, GH605 (GH5605) , GH93 (GH4093) , GH159 (GH6159) , Incoloy A-286, Inconel718, Incoloy825/2. 4858. |

|

Application

1. Erosive atmosphere of thermocouple casing

2. Production of vinyl chloride monomer: resistance to chlorine gas, hydrogen chloride, oxidation and carbonization corrosion

3. Uranium oxidation conversion to hexachloride: resistance to hydrogen chloride corrosion

4. Titanium dioxide process with chlorine gas

5. Nuclear reactors

6. Production of organic or inorganic chlorides and fluorides: resistance to chlorine and fluorine corrosion

7. Areas of production and use of caustic alkali metals, particularly in the environment where sulfides are used Curved neck bottles and components in heat treatment furnaces, especially in carbonization and nitriding atmospheres

Packing & Delivery

Standard seaworthy export packing or according to the customers' request

Economical and Affordable Transportation costs We are committed to providing economical and affordable transportation costs to save you logistics costs. In addition, we also offer the option of different timings and transportation modes, so that you can choose the most suitable solution according to your actual needs.

Hot Searches