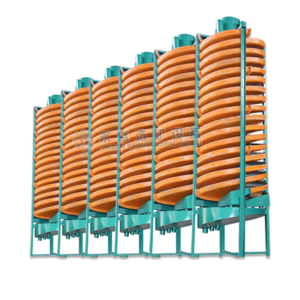

Spiral chute is the best concentrating equipment, especially for concentrating sand ore in seashore and riverside. It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; The advantages are light, moisture proof, and anti-rust, corrosive proof and no noise, properly suitable for the different feeding particle sizes and grades. The separator machine is a gravity spiral separating machine. The slurry produced inertia centrifugal force in rotary motion, and with gravity help in the same time, to promote light and heavy mineral zonation in the spiral chute, and continuous discharge respectively.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customization

-

Dimension(L*W*H):

-

different model

-

Weight:

-

3000 KG

-

Name:

-

Spiral Chute

-

Application:

-

Gravity Separator

-

Model Number:

-

LI900, DL2000

-

Installation:

-

Engineer Guidance

-

Quality:

-

High Reputation

-

Advantage:

-

High Separator Rate 96-99.99%

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Capacity:

-

1-300TPH

-

Color:

-

Customized Making

-

Price:

-

Negotiable

Quick Details

-

Production Capacity:

-

1-50tph

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongji

-

Voltage:

-

customization

-

Dimension(L*W*H):

-

different model

-

Weight:

-

3000 KG

-

Name:

-

Spiral Chute

-

Application:

-

Gravity Separator

-

Model Number:

-

LI900, DL2000

-

Installation:

-

Engineer Guidance

-

Quality:

-

High Reputation

-

Advantage:

-

High Separator Rate 96-99.99%

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Capacity:

-

1-300TPH

-

Color:

-

Customized Making

-

Price:

-

Negotiable

Product Description

Introduction of spiral chute

Features of spiral chute

1. Reasonable structure and small occupation area

2. High recovery, high efficiency, and precise separation

3. Non-required power

2. High recovery, high efficiency, and precise separation

3. Non-required power

4. Light in weight, anti corrosion, rust and wear resistant

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface

5. Simple installation and Minimal maintenance requirements

6. Low operating cost and long working life

7. Reliable running with minimal operator attention

8. Strong adaptability to fluctuation of feeding amount, density, size and grade

9. The surface of corundum forms strong friction the concentration effect surpass plastic surface

Working principle

Raise the spiral chute and fix it in the proper position, sand pump transport the ore tothe feed inlet, adding water to adjust the concentration of the slurry. The slurry naturally swirls from high to low, andgenerates an inertial centrifugal force in the rotating bevel flow rate. The mineral is separated from the sand by the gravity andcentrifugal force of the swirl by the difference in specific gravity, grain size and shape of the ore. The concentrate flows intothe concentrate bucket and is connected by the pipeline. The tail sand flows into the tailing sand bucket and is connected to the sand pool by the pipeline, and then drained by the sand pump to complete the whole process of the beneficiation.

Specification

|

Model

|

DI2000

|

DI1500

|

DI1200

|

LI900

|

LI600

|

LI400

|

|

OuterDiameter (mm)

|

2000

|

1500

|

1200

|

900

|

600

|

400

|

|

Inner Diameter (mm)

|

2000

|

1500

|

1200

|

900

|

600

|

400

|

|

Pitch (mm)

|

1200

|

900

|

720/540

|

540/360

|

390/360

|

180

|

|

Dia. Span Ratio

|

0.6

|

0.6

|

0.6

|

0.4

|

0.4

|

0.45

|

|

Tilt Angle (°)

|

9

|

9

|

9

|

9

|

9

|

9

|

|

Head Number

|

2-4

|

2-4

|

2-4

|

2-3

|

1-2

|

1-2

|

|

Number Of Turns

|

3.5

|

4

|

4-5

|

4-5

|

4-5

|

4-5

|

|

Feeding Size (mm)

|

0.04 -0.4

|

0.03-0.3

|

0.03-0.3

|

0.03-0.3

|

0.02-0.2

|

0.02-0.2

|

|

Feeding

Coneentration (%)

|

20-40

|

20-45

|

30-50

|

30-50

|

30-50

|

30-50

|

|

Capacity (t/h)

|

15-45

|

10-25

|

4-6

|

2-3

|

0.8-1.2

|

0.5-0.2

|

|

Area (㎡)

|

7

|

5

|

2

|

1.2

|

0.5

|

0.25

|

|

Height (m)

|

6.8

|

6.1

|

5.23

|

4

|

2.6

|

1.3

|

Details Images

Hot Searches