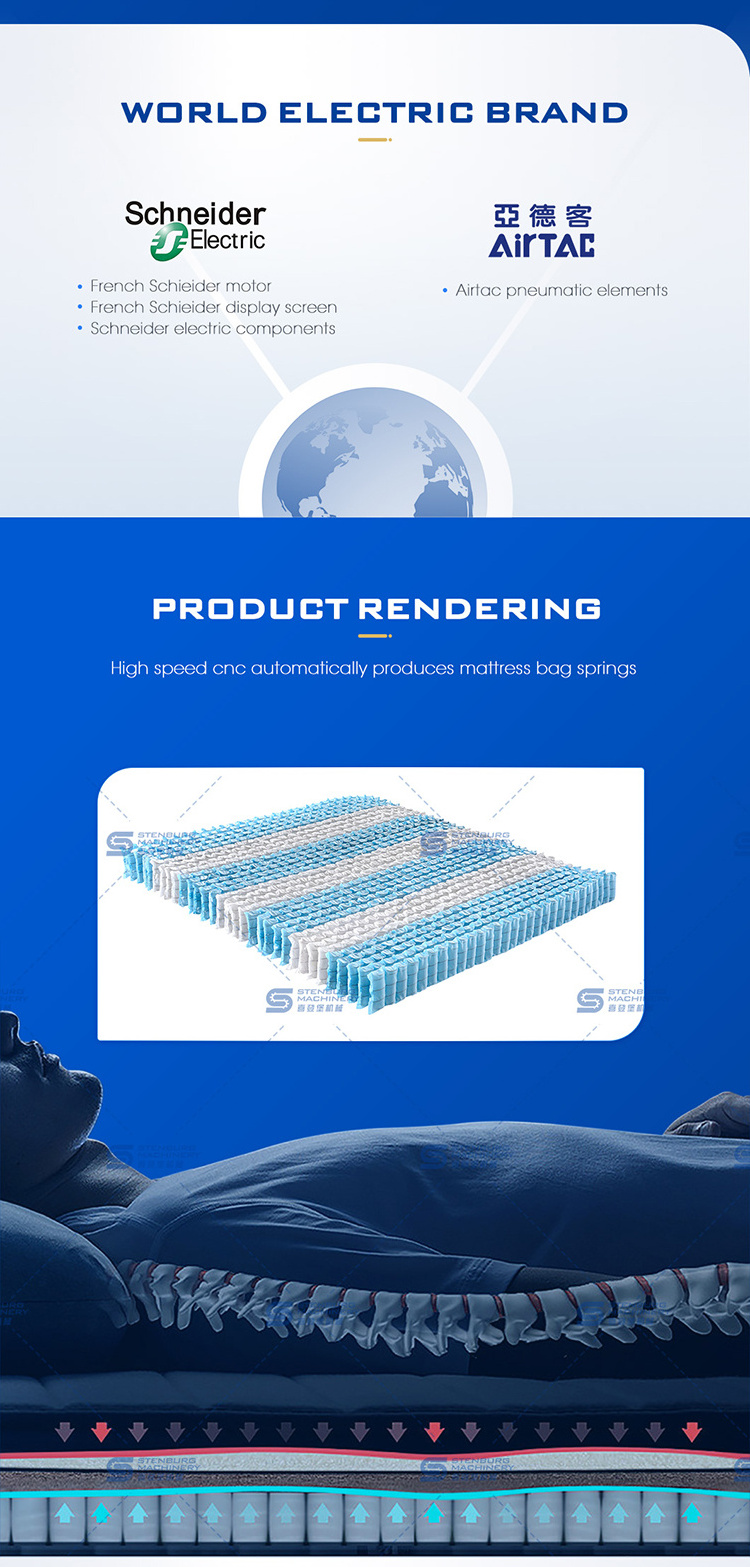

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15KW

-

Weight:

-

4500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Glueing Method:

-

Continuous gluing mode/Interrupted gluing mode

-

Inner Dia. of fabric roll:

-

Min.60mm

-

Fabric width:

-

450-2200mm

-

Outside dia. of fabric roll:

-

Max.600mm

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XIDENGBAO

-

Voltage:

-

3AC 380V 50/60 Hz

-

Power:

-

15KW

-

Weight:

-

4500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Glueing Method:

-

Continuous gluing mode/Interrupted gluing mode

-

Inner Dia. of fabric roll:

-

Min.60mm

-

Fabric width:

-

450-2200mm

-

Outside dia. of fabric roll:

-

Max.600mm

-

After Warranty Service:

-

Video technical support

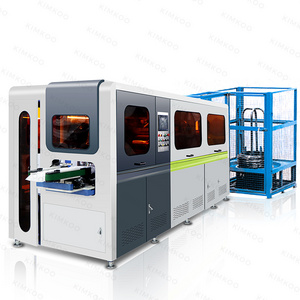

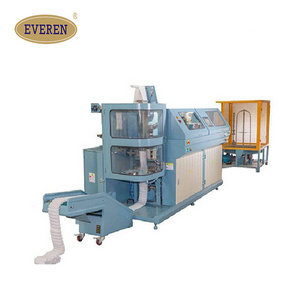

Technical Specifications

LR-PSA-98P

Pocket spring assembly machine

|

Production capacity

|

500 springs /min.

|

|

Hot melt application system

|

Nordson (the USA) or Robatech ( switzerland)

|

|

Capacity of glue tank

|

18kg/30kg

|

|

Gluing method

|

Continuous spray and general economic mode

|

|

Control of assembling platform

|

Electronic control

|

|

Possibility of assembling zoned tape

|

Possible

|

|

Possibility of assembling zoning mattress

|

Possible

|

|

Air consumption

|

0.15m³/min

|

|

Air pressure

|

0.6-0.7Mpa

|

|

Power consumption in total

|

15KW

|

|

Power requirements

|

3AC 380V 50/60 Hz

|

|

Input Current

|

25A

|

|

Cable section

|

3*10 mm²+2* 6 mm²

|

|

Working temperature

|

+5°C~ +35"C

|

|

Weight

|

4500Kg

|

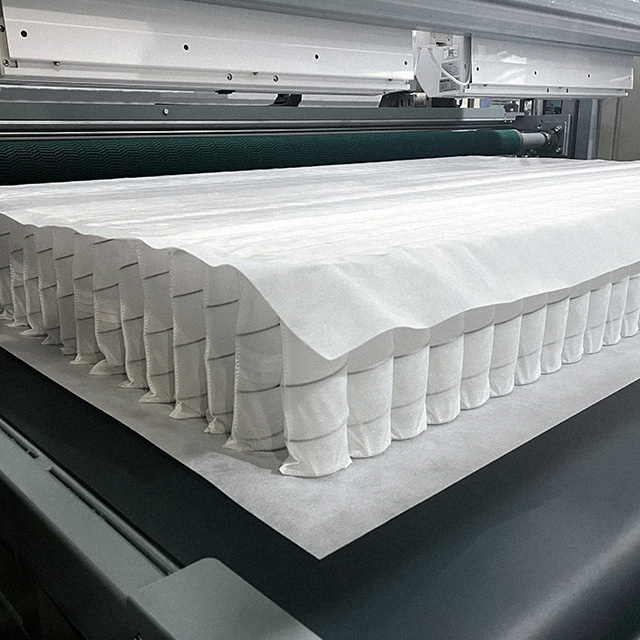

Non-woven fabric

|

Fabric density

|

65~80g/m²

|

|

Fabric width

|

450~2200mm

|

|

Inner dia. of fabric roll

|

Min.60mm

|

|

Outer dia. of fabric roll

|

Max.600mm

|

Hot melt glue

|

Shape

|

pellet or pieces

|

|

Viscosity

|

125C---6100cps

|

|

|

150C---2300cps

|

|

|

175C---1100cps

|

|

Softening point

|

85士5°C

|

|

Working range(mm)

|

|

|

|

Spring Waist Diameter

|

Φ37-75mm

|

|

|

Pocket Spring Height

|

55-250

|

|

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Searches