- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SUNY

-

Voltage:

-

Customerized

-

Dimension(L*W*H):

-

2600*1500*2020mm

-

Power (kW):

-

30

-

Weight (T):

-

2

-

Name:

-

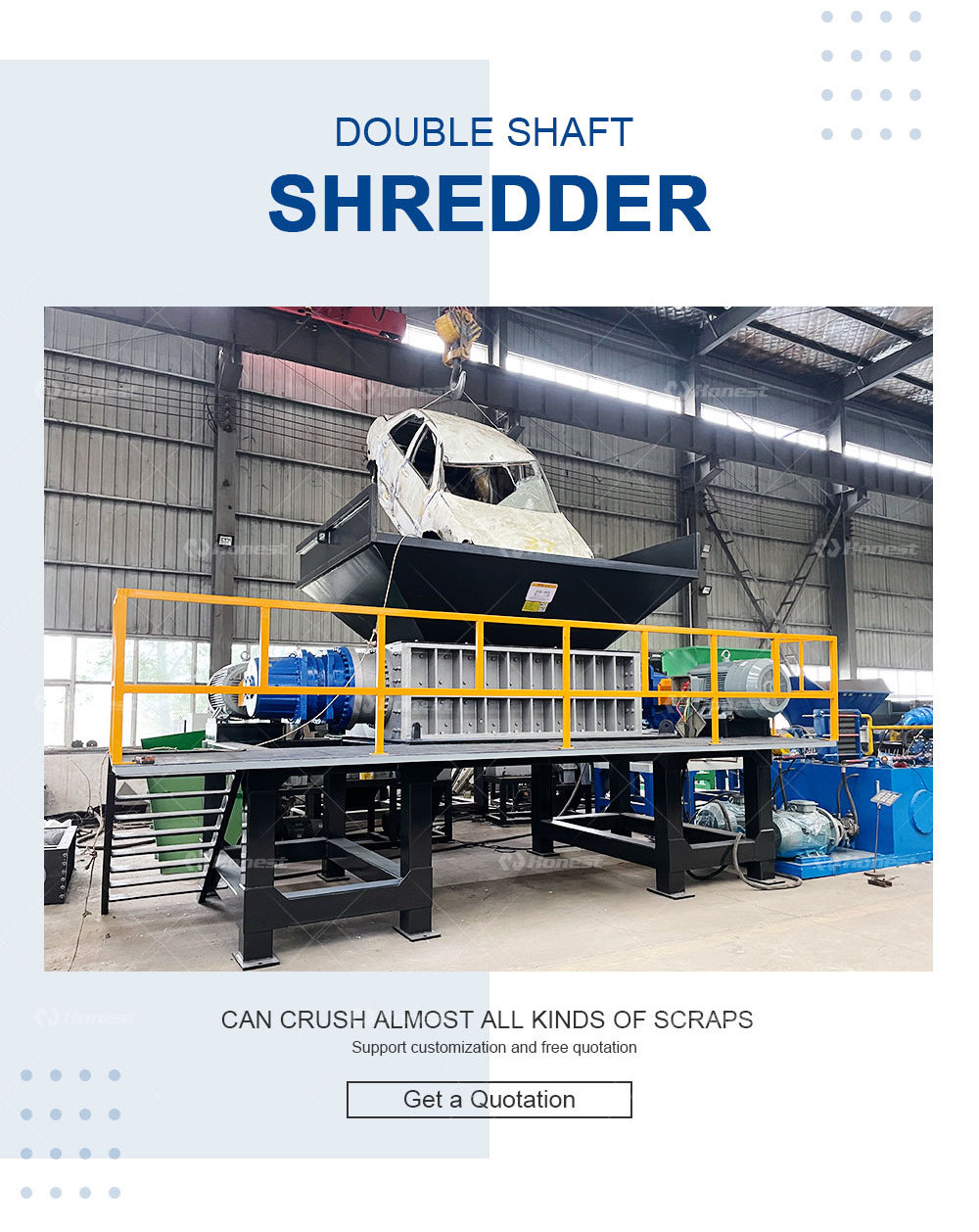

Shredding Crushing Treatment Machine Double Shaft Shredder

-

Usage:

-

Waste Raw Material Shredding

-

Color:

-

Client's Requirements

-

Final product:

-

2-10cm

-

Raw material:

-

All kinds of solid waste

-

Model:

-

SZS-600/800/1000/1200/1500/2000

-

Type:

-

Double shaft

-

Blade:

-

9CrSi SKD-11

-

Speed:

-

10-12rpm

-

Bearing:

-

ZWZ

Quick Details

-

Max.Production Capacity (kg/h):

-

17000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

100 - 15000 kg/h

-

Brand Name:

-

SUNY

-

Voltage:

-

Customerized

-

Dimension(L*W*H):

-

2600*1500*2020mm

-

Power (kW):

-

30

-

Weight (T):

-

2

-

Name:

-

Shredding Crushing Treatment Machine Double Shaft Shredder

-

Usage:

-

Waste Raw Material Shredding

-

Color:

-

Client's Requirements

-

Final product:

-

2-10cm

-

Raw material:

-

All kinds of solid waste

-

Model:

-

SZS-600/800/1000/1200/1500/2000

-

Type:

-

Double shaft

-

Blade:

-

9CrSi SKD-11

-

Speed:

-

10-12rpm

-

Bearing:

-

ZWZ

Multifunction Industrial Double Shaft Waste Car Plastic Scrap Metal Shredder Machine

Technical Parameters

|

Model

|

HNSS600

|

HNSS800

|

HNSS1000

|

HNSS1200

|

HNSS1500

|

HNSS2000

|

|

Motor Power

|

11*2 Kw

|

22*2 Kw

|

30*2 Kw

|

45*2 Kw

|

55*2 Kw

|

110*2 Kw

|

|

Capacity

|

0.2-0.6 T/H

|

0.5-1 T/H

|

1-2 T/H

|

2-4 T/H

|

4-6 T/H

|

10-15 T/H

|

|

Blade Number

|

34 Pieces

|

26 Pieces

|

34 Pieces

|

24 Pieces

|

20 Pieces

|

20 Pieces

|

|

Input Opening Size(mm)

|

950*700

|

1200*800

|

1200*950

|

2000*1500

|

2000*1500

|

2500*2000

|

|

Dimension L/W/H(m)

|

2.6*0.9*1.8

|

2.6*1.5*2.2

|

3.5*1.5*2.2

|

4.6*1.7*2.6

|

4.8*1.9*2.6

|

6.2*2.5*2.8

|

|

Weight

|

3T

|

4T

|

5 T

|

8 T

|

13 T

|

18 T

|

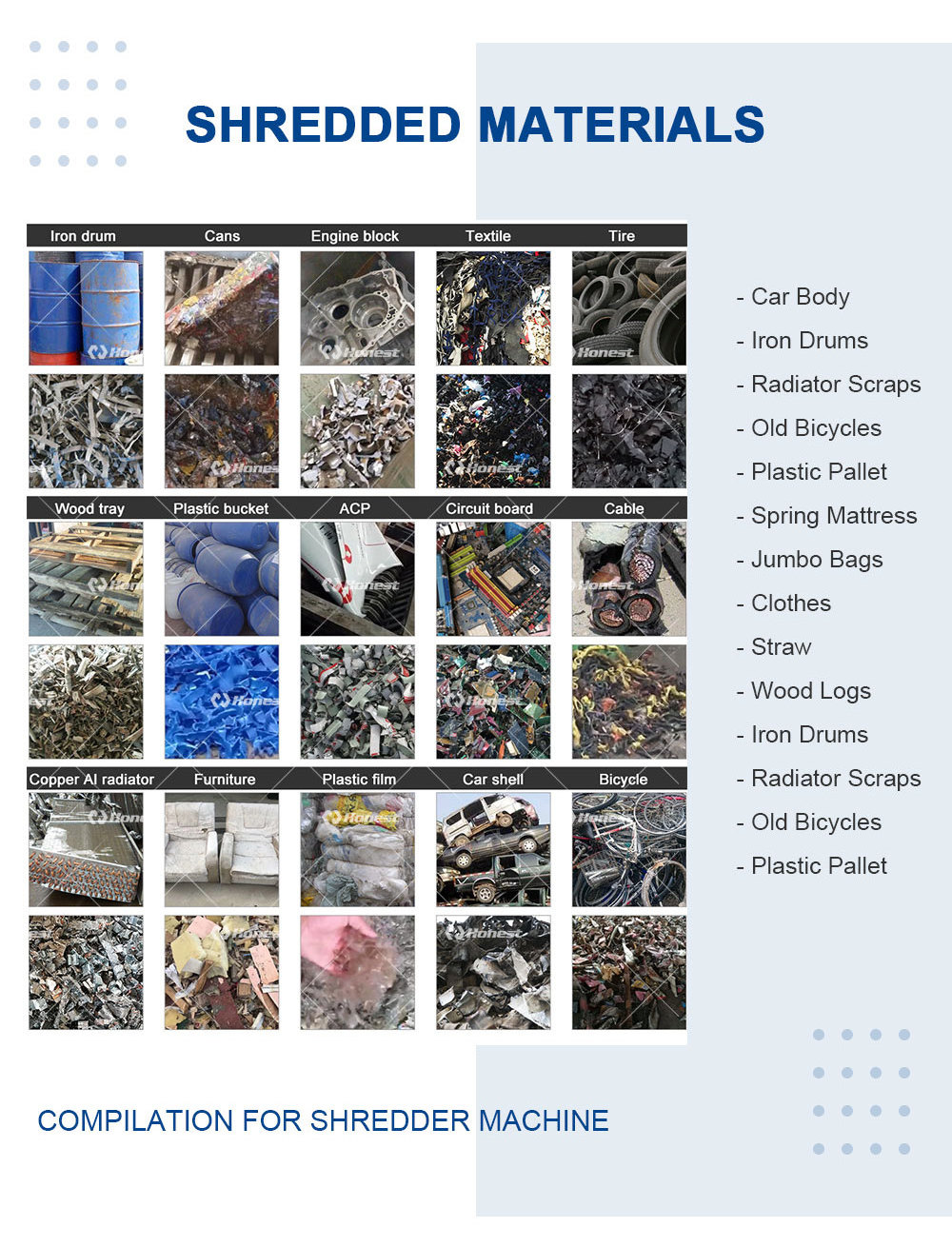

Application

1.Metal

: aluminum can bundle, steel drum, car shell, color steel tile, bicycle, copper aluminum radiator, oil filter, scrap wires, cables, aluminum composite plastic panel, steel wire rope, gas tank, iron scrap, zip-top can, engine case, paint bucket, etc.

2.Plastic

:

plastic pallet, plastic drum, plastic bucket, plastic film, waste appliances shell, garbage plastic drum, IBC drum, IBC barrel,garbage bag, rubbish bag, plastic pipe, washing machine, forklift pallet, lead acid battery shell, etc.

3.Textile

: scrap clothes, shoes, fishing net, woven bag, ton bag, jumbo bag, fishing net bundles, dust collector bag, industrial textile waste, etc.

4.Wood

: wood mattress, wood furniture, wood pallet, scrap timber, sawdust chipboard, composite board, wooden door, forklift pallet, wood board, wood template, wooden case, wooden box, wood sofa, wood bed, etc.

5.Paper

:

scrap paper and cartons, including scrap books, carton board, carton box, packaging box, waste newspaper, office paper, printing paper, paperboard, etc.

6.

Waste household appliances:

TV, washing machine, refrigerator shell etc.

7. Pipes

: large pipes, pipe fittings, PE pipes etc.

8.

Scrap tires

: car tires, truck tires etc.

9.

All kinds of

Kitchen waste

, domestic waste, rdf derivatives,garden waste etc.

Working Principle

This equipment is mainly composed of feed hopper,double shaft cutting system, Plc control system, discharging conveyor system and power system, etc.

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out.

2.Double shaft cutting system:Using different blades according customers' material.

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs.

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

1.Feed hopper: Put the material to be crushed, so as to prevent the material from splashing out.

2.Double shaft cutting system:Using different blades according customers' material.

3.Power system:We choose famous brands of motor in China, can also be configured according to customer needs.

4.Discharging conveyor system:It adopts independent power system, and that power system is integrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

Features

1. The shredder machine with big feed hopper allows us can put the big material.

2. The special design rotary knife work very efficiency.

3. The shredder machine is control by PLC control system; the blade can reverse to protect the machine and close automatically.

4. The knife is made with special alloy steel,through high temperature treatment,it can work for long life time.

5. Knife is very easy to change.

6. The machine is equipped with an extra large pulley to increase the inertia of the crusher, which can save energy and increase the crushing capacity.

2. The special design rotary knife work very efficiency.

3. The shredder machine is control by PLC control system; the blade can reverse to protect the machine and close automatically.

4. The knife is made with special alloy steel,through high temperature treatment,it can work for long life time.

5. Knife is very easy to change.

6. The machine is equipped with an extra large pulley to increase the inertia of the crusher, which can save energy and increase the crushing capacity.

Why Choose Us

Company Show

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Hot Searches