- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1145*2080*2000,1325*2497*1997,1487*3035*2555

-

Weight:

-

Custom

-

Power (kW):

-

15.11,17.86,29.3

-

Certification:

-

ce

-

Type:

-

100T,150T,250T

-

Clamping force:

-

100-250T

-

Piston diameter(mm):

-

250,300,400

-

Heating platen size(mm):

-

350*400,450*480,570*610

-

Heating piaten size(mm):

-

390*420,500*520,620*620

-

Daylight(mm):

-

140,180,200

-

Stroke(mm):

-

60,180,200

-

Vacuumdevice:

-

Vacuum cover type

-

Plate turnover angle:

-

60,45

-

Power consumption(Kw):

-

15.11,17.86,29.3

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SeaKing

-

Voltage:

-

380V/50HZ can custom

-

Dimension(L*W*H):

-

1145*2080*2000,1325*2497*1997,1487*3035*2555

-

Weight:

-

Custom

-

Power (kW):

-

15.11,17.86,29.3

-

Certification:

-

ce

-

Type:

-

100T,150T,250T

-

Clamping force:

-

100-250T

-

Piston diameter(mm):

-

250,300,400

-

Heating platen size(mm):

-

350*400,450*480,570*610

-

Heating piaten size(mm):

-

390*420,500*520,620*620

-

Daylight(mm):

-

140,180,200

-

Stroke(mm):

-

60,180,200

-

Vacuumdevice:

-

Vacuum cover type

-

Plate turnover angle:

-

60,45

-

Power consumption(Kw):

-

15.11,17.86,29.3

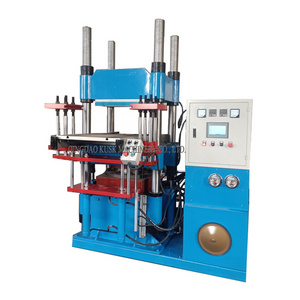

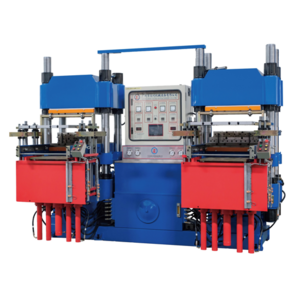

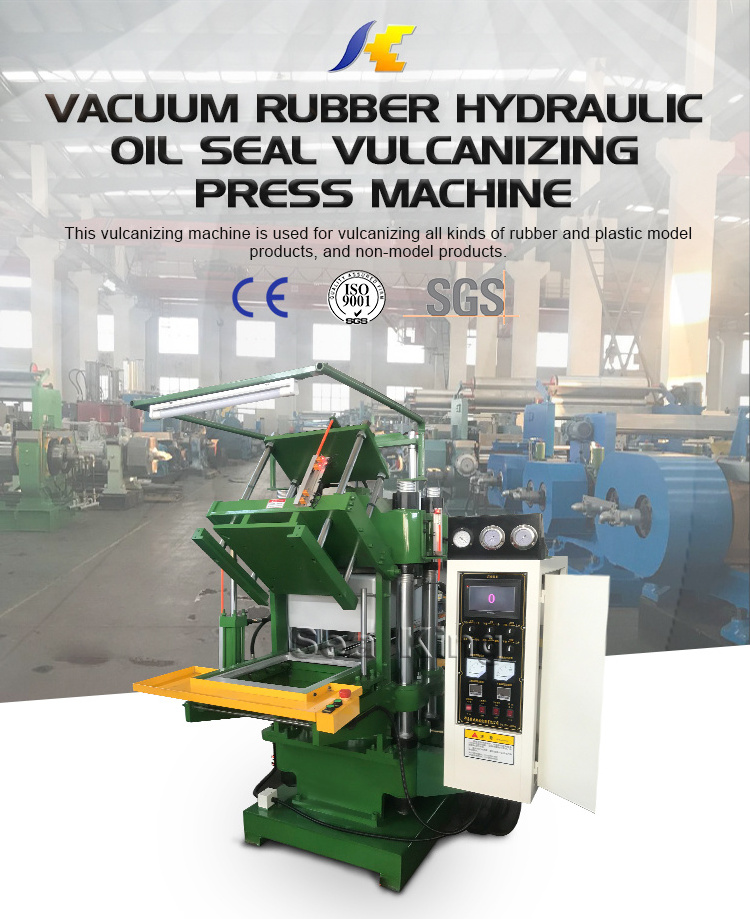

Industry Rubber O Ring Vulcanizing Press Machine

|

MACHINE TYPE |

100Ton |

150Ton |

250Ton |

|

Clamping force(KN) |

100 |

150 |

250 |

|

Piston diameter(mm) |

250 |

300 |

400 |

|

Heating platen size(mm) |

350*400 |

450*480 |

570*610 |

|

Heating piaten size(mm) |

390*420 |

500*520 |

620*620 |

|

Daylight(mm) |

140 |

180 |

200 |

|

Stroke(mm) |

60 |

180 |

200 |

|

Vacuumdevice |

Vacuum cover type |

Vacuum cover type |

Vacuum cover type |

|

Plate turnover angle |

60 |

45 |

45 |

|

Dimentions(L*W*H)(m) |

1145*2080*2000 |

1325*2497*1997 |

1487*3035*2555 |

|

Power consumption(Kw) |

15.11 |

17.86 |

29.3 |

1. Being a column structure and downward pressing type, the heating plate opens by the self-weight of the heating plate, platform and plunger. The rising of the plunger makes the heating plate close while the hydraulic oil provides the pressure.

2. dynamic template adopts lift cylinder method, realized the empty trip rising fast, slow pressure clamping when molds are shut, shorten the auxiliary time in the process of production, improve the productivity.

3. the secondary institutions, can decomposition layers mould, reduces the manual labor intensity and avoid the mould periodic damage.

4. high pressure pump, hydraulic system configuration variables, proportional pressure and flow compound valve hydraulic system, mechanical noise is lower, more smoothly, and energy saving.

5. electrical system adopts PLC control, touch display, parameter setting and the production process monitoring and convenience.

6. semi-automatic, hand move ,2 work mode, operation process, one pace reachs the designated position, the adjustment is convenient.

7. We can design and manufacture all kinds of non-standard rubber machinery according to the requirements of the customers.

The rubber vulcanizing machine applies to vulcanizing various kinds of model rubber and plastic products as well as non-model products .