- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FSD2030

-

Weight:

-

550-650

-

Width:

-

1000±20

-

Standing Temperature:

-

-70°C-280°C

-

High temperature resistant(°C):

-

≤280

-

Low temperature resistant(°C):

-

≥-40

-

Tensile intensity (N/50mm)Weft:

-

≥1280

-

Tensile intensity (N/50mm) Warp:

-

≥1750

-

Peeling intensity(N/m):

-

≥450

-

Inflating burst intensity(Mpa):

-

≥2.0

-

Insulation (kv/mm):

-

16

-

Weight (g/m*m):

-

550-650

-

color:

-

Silver-gray,gray,red

Quick Details

-

Application:

-

Blind

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VC

-

Model Number:

-

FSD2030

-

Weight:

-

550-650

-

Width:

-

1000±20

-

Standing Temperature:

-

-70°C-280°C

-

High temperature resistant(°C):

-

≤280

-

Low temperature resistant(°C):

-

≥-40

-

Tensile intensity (N/50mm)Weft:

-

≥1280

-

Tensile intensity (N/50mm) Warp:

-

≥1750

-

Peeling intensity(N/m):

-

≥450

-

Inflating burst intensity(Mpa):

-

≥2.0

-

Insulation (kv/mm):

-

16

-

Weight (g/m*m):

-

550-650

-

color:

-

Silver-gray,gray,red

Product Description

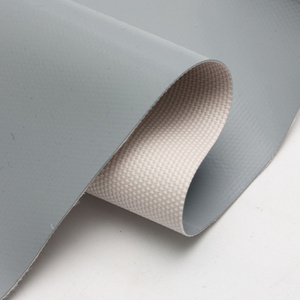

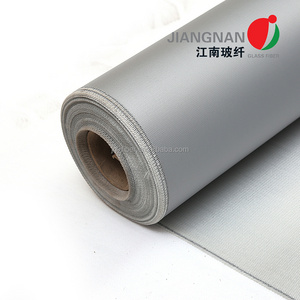

Silicone coated fiberglass fabric is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and is coated with organic silicone rubber.

Properties:

1, Good performance on resisting high temperature and low temperature, -70°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Physical and chemical index of fiberglass fabric coated with silicone rubber:

|

Product code |

FSD2030 |

FSD2030 |

FSD2050 |

FSD2100 |

|

|

High temperature resistant(°C) |

≤280 |

≤280 |

≤280 |

≤280 |

|

|

Low temperature resistant(°C) |

≥-40 |

≥-40 |

≥-40 |

≥-40 |

|

|

Tensile intensity (N/50mm) |

Warp |

≥1750 |

≥1750 |

≥2500 |

≥3500 |

|

Weft |

≥1280 |

≥1280 |

≥2100 |

≥3000 |

|

|

Inflating burst intensity(Mpa) |

≥2.0 |

≥2.0 |

≥2.2 |

≥2.6 |

|

|

Peeling intensity(N/m) |

≥450 |

≥450 |

≥520 |

≥600 |

|

|

Insulation (kv/mm) |

16 |

16 |

18 |

18 |

|

|

Weight (g/m*m) |

550-650 |

550-650 |

750-800 |

1500-1800 |

|

|

Width(mm) |

1000±20 |

1000±20 |

1000±20 |

1000±20 |

|

|

Thickness(mm) |

0.3-0.4 |

0.3-0.4 |

0.05-0.55 |

1.0-1.1 |

|

|

color |

Silver-gray, gray, red |

lucency |

Silver-gray, gray, red |

Black, gray, red |

|

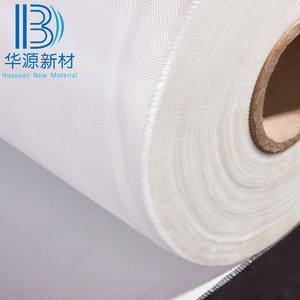

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

fiberglass fabric general properties:

1. Outstanding temperature resistance(from -70°C to +260°C)

2. Excellent chemical resistance

3. Superior non-stick surface, easy to clean

4. High dielectric strength

5. Dimensional stability

6. Resistance to UV, IR and HF

7. Non-toxic

1. MOQ: 50M2

2.FOB Price: USD3-5 / M2

3. Port: shanghai

4. Payment Terms: T / T, L / C, D / P, PAYPAL, WESTERN UNION

5. Supply Ability: 100000square meters / month

6. Delivery period: 3-10days after advance payment or confirmed L / C received

7. Standard packing: Bubble film + standard export Carton.

1. Perform a high level technology,Combining the most advanced machinery and equipment together with our coating expertise and fabrication experience.

2. Garanteed Quality: Complete quality management system combining the quality control system and complete quality assesmment reports by the third party.

3. Good service: Custom arized design advice, small to Medium batch production and complete after sales system.

4. Innovation:ongoing commitment to invest in research and development as well as state of the art manufacturing technology.