- Product Details

- {{item.text}}

Quick Details

-

MF:

-

CONH2[CH2-ch]n

-

EINECS No.:

-

207-173-7

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yigang

-

Model Number:

-

YG

-

Product name:

-

Drilling Fluids Additives Anionic Polymer Polyacrylamide

-

Appearance:

-

White Power

-

Color:

-

White Color

-

MOQ:

-

1 Ton

-

Shelf life:

-

2years

-

Sample:

-

Samples Provided

-

CAS number:

-

9003-05-8

-

Certification:

-

ISO9001

-

Application:

-

Petroleum Industry

-

Storage:

-

Cool Dry Place

Quick Details

-

CAS No.:

-

9003-05-8

-

Purity:

-

100%

-

Other Names:

-

PAM

-

MF:

-

CONH2[CH2-ch]n

-

EINECS No.:

-

207-173-7

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yigang

-

Model Number:

-

YG

-

Product name:

-

Drilling Fluids Additives Anionic Polymer Polyacrylamide

-

Appearance:

-

White Power

-

Color:

-

White Color

-

MOQ:

-

1 Ton

-

Shelf life:

-

2years

-

Sample:

-

Samples Provided

-

CAS number:

-

9003-05-8

-

Certification:

-

ISO9001

-

Application:

-

Petroleum Industry

-

Storage:

-

Cool Dry Place

Products Description

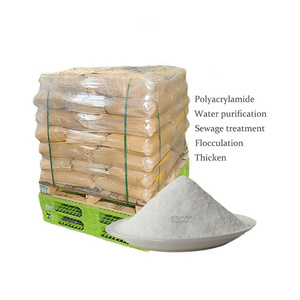

Drilling Fluids Additives Anionic Polymer Polyacrylamide/Cationic Polyacrylamide CPAM for Petroleum Industry

Polyacrylamide

is simply called PAM, a water- soluble high polymer and widely used in petroleum, paper-making, metallurgical,textile, chemical and environment protection fields. There are three categories of anionic, cationic and non-ionic type.

Polyacrylamide PAM advantages:

It is widely used in many fileds like Water Treatment, Oil Exploration, Sludge Dewatering, Paper Making, Textile, Sugar Making, Coal washing and Incense Making, etc.PAM can also be used in many other fields like Coal washing, Ore-dressing, Sludge Dewatering and so on.

Polyacrylamide PAM advantages:

Flocculation: PAM can make suspended substances through electric neutralization, bridge adsorption, and flocculation.

Adhesion: it can play a role of adhesion through mechanical, physical and chemical actions.

Resistance reduction: PAM can effectively reduce the friction resistance of the fluid, and adding a small amount of PAM in water can reduce the resistance by 50-80%

Thickening agent: PAM has thickening effect under neutral and acidic conditions, and PAM is easy to hydrolyze when PH value is over 10.When the structure is semi-reticular, the thickening will be more obvious.

Features of the Polyacrylamide in oil-field:

(1): PAM can make the flocculation of suspended matter by electrical neutralization, bridging adsorption, flocculation effect.

(2) adhesion: through the mechanical, physical and chemical effects of binder.

(3) the drag reduction of PAM can effectively reduce the fluid friction resistance

(4): PAM thickening in both neutral and acid conditions thickening effect, when the value of pH at 10 DEG PAM was easily

hydrolyzed. Semi reticulate structure, thickening will be more obvious.

(1): PAM can make the flocculation of suspended matter by electrical neutralization, bridging adsorption, flocculation effect.

(2) adhesion: through the mechanical, physical and chemical effects of binder.

(3) the drag reduction of PAM can effectively reduce the fluid friction resistance

(4): PAM thickening in both neutral and acid conditions thickening effect, when the value of pH at 10 DEG PAM was easily

hydrolyzed. Semi reticulate structure, thickening will be more obvious.

Application method:

1.Dissolution: Dissolve solid PAMto 1‰—5‰ water solution before using. When dosage, it should be added into water slowly to ensure that the chemical can be dissolved

2.Solution dosage: Normallythe water solution is 1‰—5‰, but with high concentration and high viscosity suspension, it is advised to dilute water solution to 0.1‰ to get a better (Trying to avoid using high-shear centrifugal pumps to dissolve the solution to prevent the molecular chain from being cut)

3.Compared with anionic PAM, cationic onehas lower molecular weight, so does the Therefore, cationic and nonionic PAM have higher concentration ratio than anionic PAM. Recommended concentration is 1‰—5‰.

1.Dissolution: Dissolve solid PAMto 1‰—5‰ water solution before using. When dosage, it should be added into water slowly to ensure that the chemical can be dissolved

2.Solution dosage: Normallythe water solution is 1‰—5‰, but with high concentration and high viscosity suspension, it is advised to dilute water solution to 0.1‰ to get a better (Trying to avoid using high-shear centrifugal pumps to dissolve the solution to prevent the molecular chain from being cut)

3.Compared with anionic PAM, cationic onehas lower molecular weight, so does the Therefore, cationic and nonionic PAM have higher concentration ratio than anionic PAM. Recommended concentration is 1‰—5‰.

The technical parameter of polyacrylamide

|

Item

|

Standard

|

|

|

||

|

Main technical indicators

|

Anionic

|

Nonionic

|

Cationic

|

||

|

Appearance

|

White granule/power

|

White granule/power

|

White granule/power

|

||

|

Dissolving time (mins)

|

<40

|

<40

|

<40

|

||

|

Molecular weight (ten thousand)

|

300-2500

|

300-1600

|

300-1600

|

||

|

Degree of hydrolysis (%)

|

5-35

|

5-15

|

10-80

|

||

|

Solid content (%)

|

≥90

|

≥90

|

≥90

|

||

|

Insoluble Content (%)

|

≤0.2

|

≤0.2

|

≤0.2

|

||

|

Residual Monomer (%)

|

≤0.05

|

≤0.05

|

≤0.05

|

||

Hot Searches