- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0.5KW

-

Dimension(L*W*H):

-

700mm*410mm*500mm

-

Dry ice volume:

-

9 KG (MAX)

-

Jet pressure::

-

1.5-10bar

-

Air flow rate::

-

2-4 cubic meters/min

-

Application:

-

Mould Cleaning

-

Design power supply of the equipment::

-

AC110-230V 50/60Hz

-

Power::

-

0.5 Kw 3Ph

Quick Details

-

Weight (KG):

-

52

-

Place of Origin:

-

JIANGSU

-

Brand Name:

-

Mixer

-

Power:

-

0.5KW

-

Dimension(L*W*H):

-

700mm*410mm*500mm

-

Dry ice volume:

-

9 KG (MAX)

-

Jet pressure::

-

1.5-10bar

-

Air flow rate::

-

2-4 cubic meters/min

-

Application:

-

Mould Cleaning

-

Design power supply of the equipment::

-

AC110-230V 50/60Hz

-

Power::

-

0.5 Kw 3Ph

Equipment name and specification and model

Name: Dry ice blasting machine

model: HG-LC

Main equipment (HG-LC) technical performance:

Equipment size: 700mm*410mm*500mm

Equipment weight: 52 KG

External material: SUS304 sheet metal

Air flow rate: 2-4 cubic meters/min

Jet pressure: 1.5-10bar

Dry ice volume: 9 KG (MAX)

Dry ice consumption: 0-36 KG/H

Size of dry ice: 120*120*250MM to 150*150*300MM

Design power supply of the equipment: AC110-230V 50/60Hz

Power: 0.5 Kw 3Ph

HG-LC dry ice blasting machine principle:

The block dry ice is cut by the cutter head, the dry ice is supplied quantitatively and evenly by the ice distribution device, the dry ice is transported by the pipeline, and finally the dry ice is sprayed at high speed by the nozzle, and the dry ice particles are sprayed to the surface to be cleaned at a high speed and uniformly, so as to realize dry and non-destructive cleaning.

Equipment technical parameters:

It is mainly composed of control system, protection system, quantitative ice delivery device, anti-blocking system, dry ice hopper, jet pipe and nozzle.

M ain parameter:

Adjustment range of dry ice dosage: 0-600g / min

Air pressure adjustment range: 0-10bar

Compressed air flow rate: 2-4M3/min

Range of dry ice particles: 0.1-0.5mm

S ecurity function:

1. There are double anti-misoperation switches on the spray gun to prevent safety accidents, ice spraying or blowing can be switched, equipped with lighting observation

2. Automatic emergency stop protection for equipment that opens the warehouse door

3. Ice spray tube quick connector, high pressure resistance, low temperature resistance, bending resistance

4. Overpressure protection, equipped with manual pressure relief valve, reducing safety hazards in disassembly and assembly

5. Anti-static function

Description of equipment stability, operation type, Maintainability, and energy saving

a. Stability:

The main components and components of the equipment are all well-known brand products with stable performance to ensure that the speed of dry ice remains stable during the spraying process.

b. Operability:

The operation of the equipment is simple, using a friendly human-machine cooperation interface, the handle is ergonomic, and it is not tiring to operate for a long time. As long as workers who know a little about mechanical operation can master the operation of the equipment after simple training.

c. Maintenance:

The maintenance of the equipment is convenient and simple, usually only need to do simple daily inspection and maintenance, the whole machine is designed in stainless steel, and can be washed directly with hot water after returning to temperature.

d. Energy saving:

Block dry ice, scrape as much as you use, and the amount of ice output can be adjusted.

Application:

The application range of dry ice blasting is quite wide, such as: automobile industry, electric power industry, petrochemical industry, chemical fiber and chemical textile industry, food industry, medical pharmaceutical industry, electronic industry, etc.

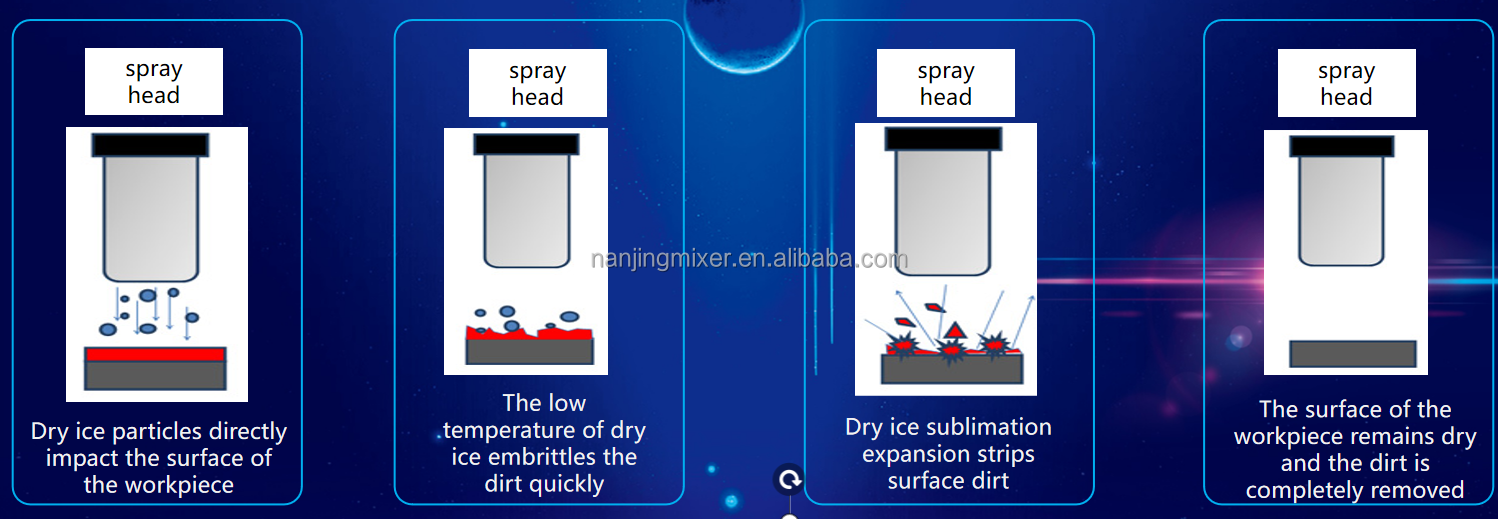

The principle of dry ice blasting machine:

through external compressed air, dry ice particles are ground and sprayed onto the surface of the workpiece to be cleaned, and the impact of dry ice particles and the physical characteristics of the temperature difference between dry ice and the surface of the object are used to make different substances produce brittleness under different shrinkage speeds. A cleaning method for detachment. When the dry ice particles at -78°C touch the surface of the dirt, an embrittlement explosion will occur, causing the dirt to shrink and loosen. Then the dry ice particles will instantly gasify and expand 800 times, and a strong peeling force will be generated during the process. The dirt is quickly and thoroughly stripped from the surface of the object, so as to achieve a fast, efficient, safe and energy-saving cleaning effect. Note: The dry ice raw material (carbon dioxide) used in the dry ice blasting machine is obtained from industrial waste gas and high-altitude air separation. Dry ice blasting itself does not produce carbon dioxide.

Application example of cleaning mold

Features of Dry Ice Cleaning Mold

1. It can be cleaned online directly without cooling down and disassembling the mold, which improves production efficiency. 2. It avoids the corrosion and damage of the mold by chemical cleaning method, the mechanical damage and scratch of the mold by mechanical cleaning method, and the decrease of mold precision caused by repeated loading and unloading. 3. The key point is that the two most time-consuming steps of dismantling the mold and waiting for the mold to cool down can be avoided, which can reduce downtime by about 80%-95% 4. The cost of cleaning is low. Based on the cost savings in the above aspects of reducing labor and improving efficiency, the direct cost of dry ice cleaning is also very low. 5. Calculated based on a pair of 1.5m × 1.5m square molds, the cleaning time is about 30 minutes, and it needs to consume 2-3 pieces of dry ice (each piece of ice weighs 6 kg, 5 pieces per kilogram