- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Dust removal machine

-

Function:

-

dedusting

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After-sales Service Provided1:

-

Field maintenance and repair service

-

After-sales Service Provided2:

-

Video technical support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MF

-

Weight (KG):

-

200

-

Type:

-

Dust removal machine

-

Function:

-

dedusting

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After-sales Service Provided1:

-

Field maintenance and repair service

-

After-sales Service Provided2:

-

Video technical support

This machine is equipped with dust-removing double-bristle brush, attached with strong blower dust-removing device, which can automatically remove the dust on the surface of the substrate and improve the coating quality. Brush rear, the front as a transport overuse, dust transport two in one.

|

1. Effective processing width:

|

0-1300mm

|

|

2. Effective machining thickness:

|

2-80mm

|

|

3. Minimum processing length:

|

300mm

|

|

4. Conveying speed:

|

0-20m/min

|

|

5.Brush wheel size:

|

¢150×1320 mm

|

|

6. Pressure wheel size:

|

¢60×1320 mm

|

|

7. Driving iron wheel size:

|

¢130×1330 mm

|

|

8. Machine size:

|

3000mm×2200mm×1500mm

|

Main configuration and parameters:

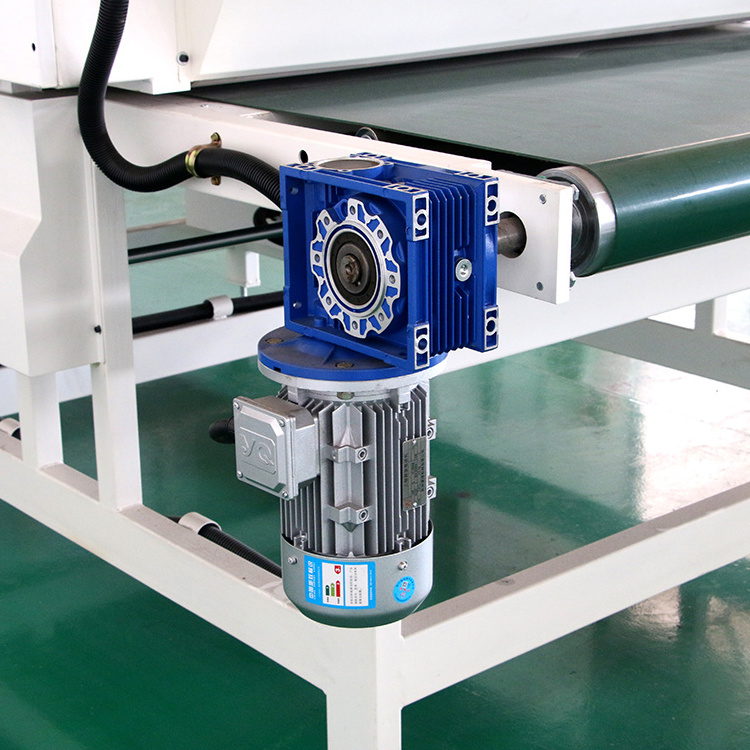

Power: AC three-phase four-wire 380V 50HZ total power: 6KW

1. Transmission power is controlled by frequency conversion motor.

2. Adopt Taiwan frequency converter to control the transmission speed.

3. Dust brush: 2 high-quality brown brush, which can effectively remove dust generated after the surface sanding of the plate.

4. The dust removal box is equipped with 4 small fans *, which conforms to the principle of gas flow mechanics and maximizes the absorption of dust in the brush frame.

5. The outlet is equipped with a high-power dust removal fan *1.

6. Equipped with 3 pressure wheels and made of wear-resistant rubber.

7. The lifting seat is made of cast iron dovetail groove, ensuring precision and rigidity of the body.

8. Conveyor belt adopts 3MM PVC flat belt, resistant to high temperature and corrosion, with long service life.

Foshan nanhai mingfeng machinery factory is a professional company engaged in the research and development, design, manufacture, sales and service of coating machinery equipment. With years of experience in the production of coating equipment, through their own continuous technical innovation and market research, absorbing the advanced industry at home and abroad, gradually formed their own product series, highly praised by the majority of users

Company's main: automatic spray paint, spray coating machine, coating machine, wood grain printing machine, coating machine (spray coating machine, coating machine, UV coating production lines, etc.), automatic spray painting machine, door, door cover line printer printing machines, play crural line printer, furniture plate paint line, calcium silicate board paint line, gusset plate, shutter printing presses, heel and sole press coating equipment.

The company is located in honggang industrial zone, lishui town, nanhai district, foshan city, guangdong province, China. Foshan nanhai mingfeng machinery factory, in line with the principle of "customer first, integrity first", has established long-term cooperative relations with many enterprises. Warmly welcome friends from all walks of life to visit, study and negotiate business.