- Product Details

- {{item.text}}

Quick Details

-

Power:

-

50-1000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

50000 kg

-

Product name:

-

Best Price Calculation Lime Rotary Kiln For Construction

-

Application:

-

Active Lime Plant

-

Capacity:

-

50-1000tpd

-

Spare Parts Supply:

-

Supply at lowest price

-

Installation and trial:

-

Send Engineer

-

Factory Visit:

-

Invitation Letter

-

Design drawings:

-

Provided

-

Quality:

-

International Standard

-

Calcination material:

-

Limestone, Cement clinker

-

After-sales Service Provided:

-

Online support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNISHINE

-

Voltage:

-

220-480V

-

Power:

-

50-1000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

50000 kg

-

Product name:

-

Best Price Calculation Lime Rotary Kiln For Construction

-

Application:

-

Active Lime Plant

-

Capacity:

-

50-1000tpd

-

Spare Parts Supply:

-

Supply at lowest price

-

Installation and trial:

-

Send Engineer

-

Factory Visit:

-

Invitation Letter

-

Design drawings:

-

Provided

-

Quality:

-

International Standard

-

Calcination material:

-

Limestone, Cement clinker

-

After-sales Service Provided:

-

Online support

|

Model |

Diameter of cylinder (mm) |

Length of cylinder (mm) |

Inclination (%) |

Capacity (t/h) |

Rotation speed (rpm) |

Power (kw) |

Weight (t) |

|

YZ1225 |

1200 | 25000 | 4 | 3 |

0.53-5.25 |

22 | 34 |

|

YZ1632 |

1600 | 32000 | 4 | 3.5 |

0.53-5.25 |

15 | 46 |

|

YZ1828 |

1800 | 28000 | 4 | 4 |

0.28-2.84 |

30 | 59 |

|

YZ1845 |

1800 | 45000 | 4 | 4.5 |

0.28-2.84 |

30 | 80 |

|

YZ1636 |

1600 | 36000 | 4 | 1.2-1.9 |

0.26-2.61 |

22 | 51 |

|

YZ1939 |

1900 | 3900 | 4 | 1.6-3.4 |

0.31-2.82 |

37 | 70 |

|

YZ2044 |

2000 | 44000 | 3.5 | 2.4-4 |

0.22-2.26 |

37 | 97 |

|

YZ2245 |

2200 | 45000 | 3.5 | 3.2-5.3 |

0.23-2.25 |

45 | 125 |

|

YZ2550 |

2500 | 50000 | 3.5 | 6.2-7.4 |

0.68-1.45 |

55 | 179 |

|

YZ2555 |

2500 |

55000 |

3 | 7.3-9.8 | 0.79-2.38 | 55 | 191 |

|

YZ2820 |

2800 |

20000 |

4 |

15-18 |

0.8-1.45 |

75 | 186 |

| YZ3028 | 3000 |

28000 |

4 | 18-23 |

0.8-1.45 |

75 | 180 |

| YZ3060 | 3000 | 60000 | 3.5 |

16-20 |

0.49-2.41 | 90 | 272 |

| YZ3226 | 3200 | 26000 | 4 | 22-27 | 0.8-1.45 | 90 | 185 |

| YZ3255 | 3200 | 55000 | 3.5 |

17-23 |

0.1-1.52 |

75 | 271 |

| YZ3529 | 3500 | 29000 | 4 |

28-40 |

0.16-1.38 |

110 | 238 |

|

YZ3560 |

3500 | 60000 | 3.5 | 28-40 | 0.65-2.25 | 125 | 347 |

| YZ4030 | 4000 | 30000 | 4 | 52-70 | 0.38-3.52 | 160 | 415 |

|

YZ4060 |

4000 | 60000 | 3.5 | 55-78 | 0.38-3.52 | 315 | 514 |

|

YZ4262 |

4200 | 62000 | 3.5 | 80-105 |

0.38-3.52 |

315 | 541 |

| YZ4565 | 4500 | 65000 | 3.5 |

110-140 |

0.38-3.52 |

420 | 609 |

| YZ4772 | 4700 | 72000 | 3.5 |

150-190 |

0.38-3.52 |

550 | 795 |

| YB1626 | 1600/1400 | 26000 | 4 | 0.7-11 |

0.41-3.85 |

18.5 | 38 |

|

YB1939 |

1900/1600 | 39000 | 4 |

2.2-2.7 |

0.27-2.58 |

22 | 60 |

| YB2245 | 2200/2000 | 45000 | 3.5 |

2.5-3.5 |

0.25-2.28 | 30 | 88 |

| YB2545 |

2500/2200 |

45000 | 3.5 | 4.5-6.2 | 0.25-2.18 | 45 | 102 |

| YB2845 |

2800/2500 |

45000 | 3.5 |

7.5-10 |

0.68-1.45 |

55 | 192 |

| YB3560 |

3500/3000 |

60000 | 3.5 |

23-32 |

0.65-2.28 | 125 | 310 |

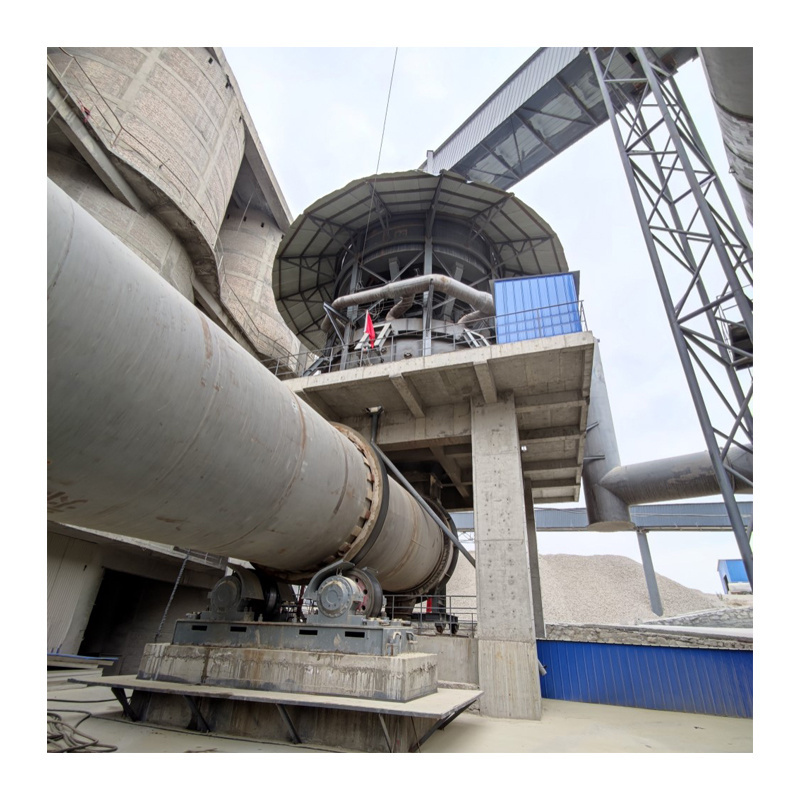

Cement rotary kiln

Capacity: 180-10000t/d

Applicable materials: Cement, cement brick, refractory charge, clay, bentonite, etc.

Application: Cement rotary kiln is the main equipment of dry and wet cement clinker production lines, which is widely used in metallurgy, chemical industry, building refractory materials, environmental protection and other industries.

Brief Introduction:Cement rotary kiln is the main equipment of dry and wet cement clinker production line, which is mainly used for calcining cement clinker.It is divided into two categories: dry production cement kiln and wet production cement kiln.

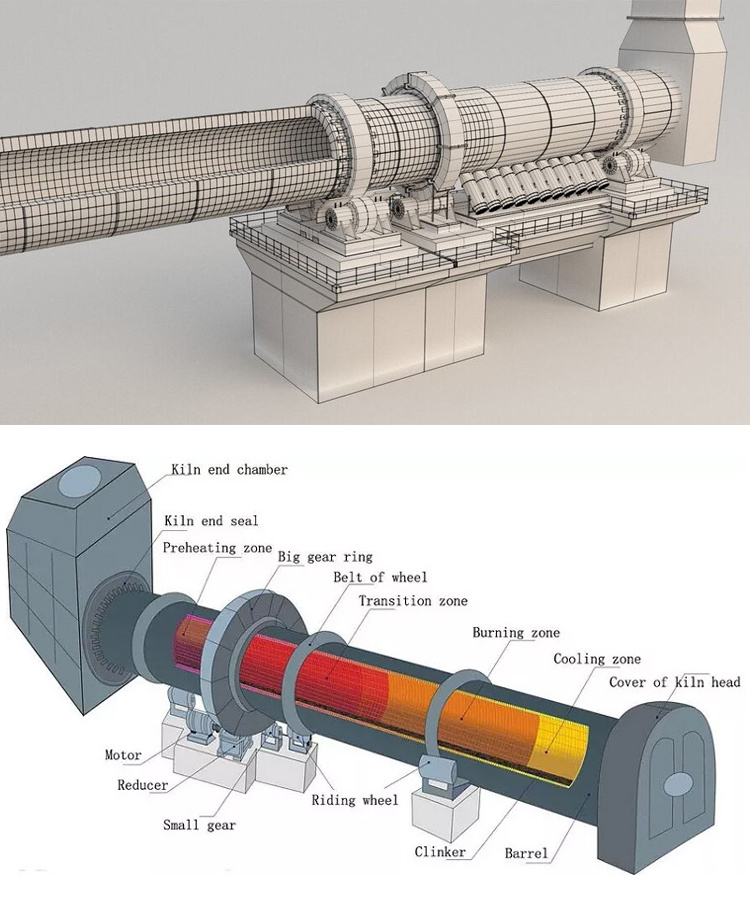

Introduction

Cement rotary kiln is the main equipment of dry and wet cement clinker production line, which is mainly used for calcining cement clinker.It is divided into two categories: dry production cement kiln and wet production cement kiln. Solid structure, stable operation, high quality of kiln products, and can provide users with advanced high efficiency vertical preheater and five-stage cyclone preheater.

Characteristics

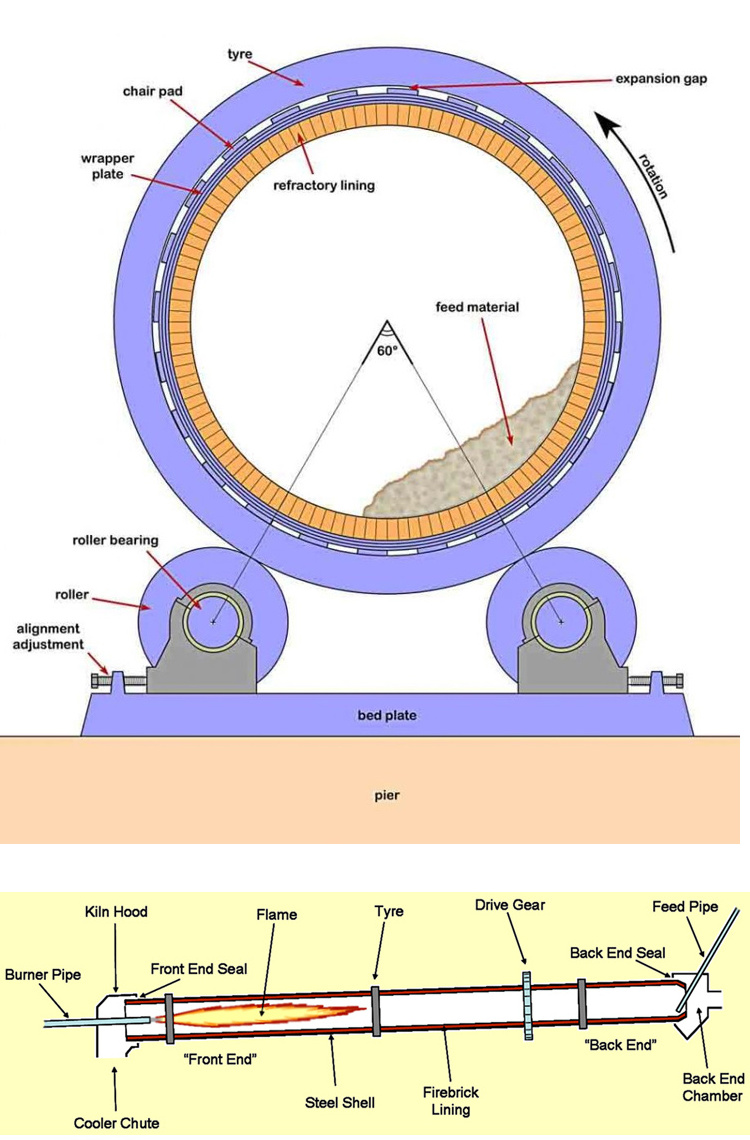

1. High thermal efficiency

The material is heated uniformly and fully in the cylinder, and the heat transfer is rapid. On the other hand, the material and the gas flow in the reverse direction, and the heat is fully utilized. The exhaust gas passes through the preheater at the kiln end, and the heat is reused to dry the material, and the finished lime is taken out. The heat is converted into hot air by the cooler under the kiln head and then returned to the kiln, which greatly improves the thermal efficiency of the kiln.

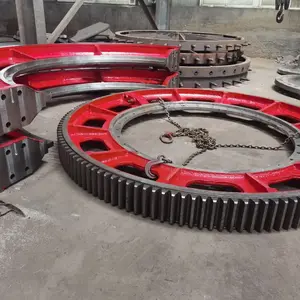

2. Advanced structure

The kiln body of the cement rotary kiln has a certain inclination angle to the horizontal. The entire kiln body is supported by a supporting roller device, and has a wheel blocking device that controls the kiln body to move up and down. In addition to the main drive, the drive system is also equipped with an auxiliary drive device which can make the kiln body rotate when the main power supply is cut off, so as to prevent the kiln body from bending and deformation.

3. Stable and reliable performance

Through continuous improvement and innovation by scientific researchers, the cement rotary kiln overcomes the shortcomings of traditional equipment such as difficult temperature control, unstable product quality, large energy consumption, serious environmental pollution, and low thermal efficiency. The rotary kiln finished product has good quality and high output.

4. High output and low energy consumption

Compared with traditional equipment, the cement rotary kiln is easy to operate and reliable in use. The operation rate is increased by 10%, the output is increased by 5%-10%, and the heat consumption is reduced by 15%.