- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ACE

-

Voltage:

-

110V-440V

-

Power:

-

0.75KW-115KW

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

800

-

Product name:

-

Reactor

-

Material:

-

stainless steel 304/316L

-

Heating method:

-

electric heating, steam heating and oil

-

Mixing Type:

-

anchor type, frame type, oar type, turbo type, etc.

-

The heating and cooling:

-

jacket, semi-tube and coil structure etc.

-

Application:

-

Paint, glue, resin, chemical, liquid

-

Usage:

-

Food ,chemical , beverage , dairy ,ects

-

Function:

-

Heating , cooling , mixing , insulation

-

Rotation speed:

-

18~ 200 (customizable)

-

Control Device:

-

Automatic Controller

Quick Details

-

Capacity:

-

100L-30000L

-

Marketing Type:

-

New Products 2024

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

110V-440V

-

Power:

-

0.75KW-115KW

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

800

-

Product name:

-

Reactor

-

Material:

-

stainless steel 304/316L

-

Heating method:

-

electric heating, steam heating and oil

-

Mixing Type:

-

anchor type, frame type, oar type, turbo type, etc.

-

The heating and cooling:

-

jacket, semi-tube and coil structure etc.

-

Application:

-

Paint, glue, resin, chemical, liquid

-

Usage:

-

Food ,chemical , beverage , dairy ,ects

-

Function:

-

Heating , cooling , mixing , insulation

-

Rotation speed:

-

18~ 200 (customizable)

-

Control Device:

-

Automatic Controller

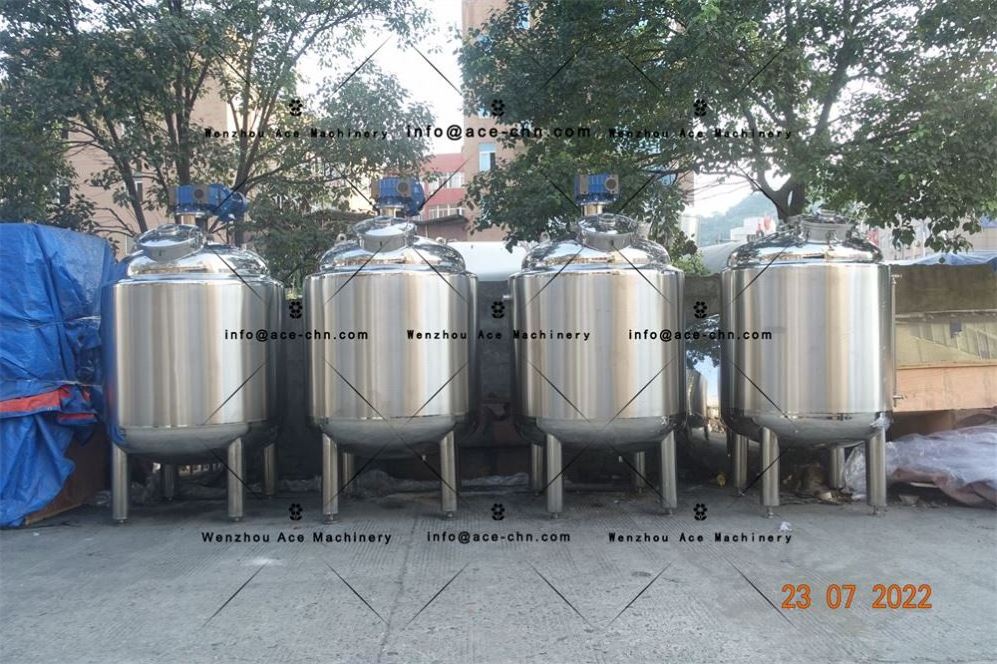

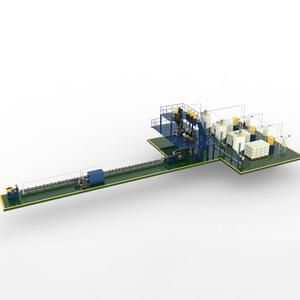

Ace Industrial Stirred Glue Making Agitated And Jacket Reactor For Melt Adhesive Machine Line

Custom Made 50L- 30,000L, 22 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products. Please

contact us for the offer.

We are specialists in the design, manufacture and installation of reactor tanks of all types according to the specifications of your industry to equip your plants with the type of chemical reactor that your activity requires.

Whether you need a Bach reactor, a complete mix reactor (CSTR, CFSTR), a piston flow reactor, etc... At Ace, we can build it.

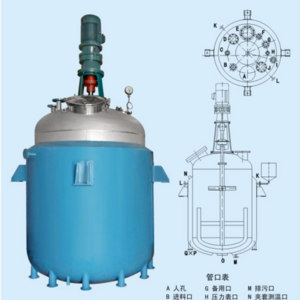

Reference technical parameters

1. Tank body: stainless steel (SUS304, SUS316L) material, the inner surface of the mirror polishing,

2. Can be online CIP cleaning, SIP sterilization, in line with health norms

3. Mixing device: optional box-type, anchor type, such as pulp

4. Heating and cooling: steam heating or electric heating can be used

5. Stirring shaft seal with pressure hygiene mechanical seal device to maintain the working pressure inside the tank and to prevent leakage of materials within the tank.

6. Support type According to the operational requirements of the use of hanging ear-type or floor leg type.

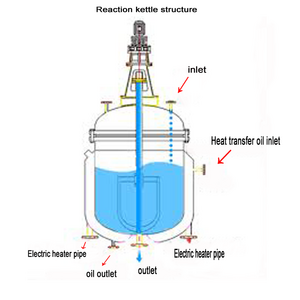

Agitation for Efficiency

Agitation can make the difference between a reaction working or not working. It also affects high and low yields by making sure

the temperatures are spread evenly and your ingredients mixed thoroughly as your product is processing.

the temperatures are spread evenly and your ingredients mixed thoroughly as your product is processing.

We work with you and your specific process to help eliminate the hot and cold spots and reach the appropriate mixing levels required for an efficient

reaction.

reaction.

This reactor is used for hydrolysis, neutralization, crystallization, distillation and evaporation in the fields of chemicals, food, light industry etc. The reactor body is made of sus304, sus316l stainless steel.

Several mixing type is available Structure

1. The equipment is mainly composed of three parts: a cylinder, an integral jacket and an outer covering. The outer covering and the jacket are filled with insulation medium, and the tank top is equipped with a stirrer.

2. The pressure inside, the jacket is determined according to customer requirements.

3. The materials are all high-quality stainless steel.

Characteristics:

1. Applicable for concocting finished products or mixing different phases of materials in coating, dyes, pigments, printing inks,

pesticide and paper-making industries, etc. It can be fitted with many kinds of mixers, which are suitable for different working

conditions.

Characteristics:

1. Applicable for concocting finished products or mixing different phases of materials in coating, dyes, pigments, printing inks,

pesticide and paper-making industries, etc. It can be fitted with many kinds of mixers, which are suitable for different working

conditions.

2. As per different requirements, the kettle is able to be made into many types such as vacuum, normal-pressure, pressure-proof, cooling, heating and so on.

3. Various blades as paddle, frame and anchor with low speed running can be chosen.

Also, the kettle, normally with single layer structure, can be made into normal pressure, pressure-proof types, etc.

Also, the kettle, normally with single layer structure, can be made into normal pressure, pressure-proof types, etc.

|

Reactor Tank (Support for customization)

|

|

|

|

|||

|

Profile/type

|

Single layer tank

|

Double layer tank

|

Three layer tank

|

|||

|

Material

|

SS304 or SS316L

|

|

|

|||

|

Volume

|

50L-30T (Customized)

|

|

|

|||

|

Pressure

|

Vacuum-1Mpa

|

|

|

|||

|

Tank Type

|

Vertical type/Horizontal type/Mobile type

|

|

|

|||

|

Structure

|

one layer

|

Inner layer+jacket

|

inner layer+jacket+insulation

|

|||

|

heating way

|

Electric/Steam Heating

|

|

|

|||

|

Inside Finsh

|

Mirror polished Ra<0.4um

|

|

|

|||

|

Outside Finish

|

2B or Satin Finish

|

|

|

|||

|

Stirrer type

|

impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

|

|

|||

|

|

|

|

|

|||

|

Power

|

0.55~55KW

|

|

|

|||

|

Voltage

|

110V~480V

|

|

|

|||

|

Top Head type

|

Dish top, Open lid top, Flat top

|

|

|

|||

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

|

|||

|

PARTS DETAILS

|

1.Quick open manhole / Pressure manhole

|

|

|

|||

|

|

2.Various types of CIP cleaners

|

|

|

|||

|

|

3.Sterile respirator

|

|

|

|||

|

|

4.Adjustable Legs

|

|

|

|||

|

|

5.Inlet and Outlet sanitary valve

|

|

|

|||

|

|

6.Thermometer (According to customer requirements )

|

|

|

|||

|

|

7.Paddle blender .(According to customer requirements)

|

|

|

|||

|

|

8.Liquid level meter and lever controller (According to customer requirements)

|

|

|

|||

|

|

9.Ladder

|

|

|

|||

|

Application

|

Food, Beverage, biological, honey, chocolate, alcohol, chemical industry etc

|

|

|

|||

|

We can customize the equipment according to customer requirements.

|

|

|

|

|||

Details Images

Product packaging

We are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require

* Strict packing process to ensure the safety and completeness of the goods

Certifications

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in a plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend, and we sincerely do business and make friends with them, no matter where they come from.

Contact Us

Hot Searches