- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

40mm

-

Control Software:

-

FSCUT 4000E

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jntech

-

Weight (KG):

-

6000 KG

-

Core Components:

-

laser

-

Electric Proportional Valve:

-

Japan SMC Electric Proportional Valve

-

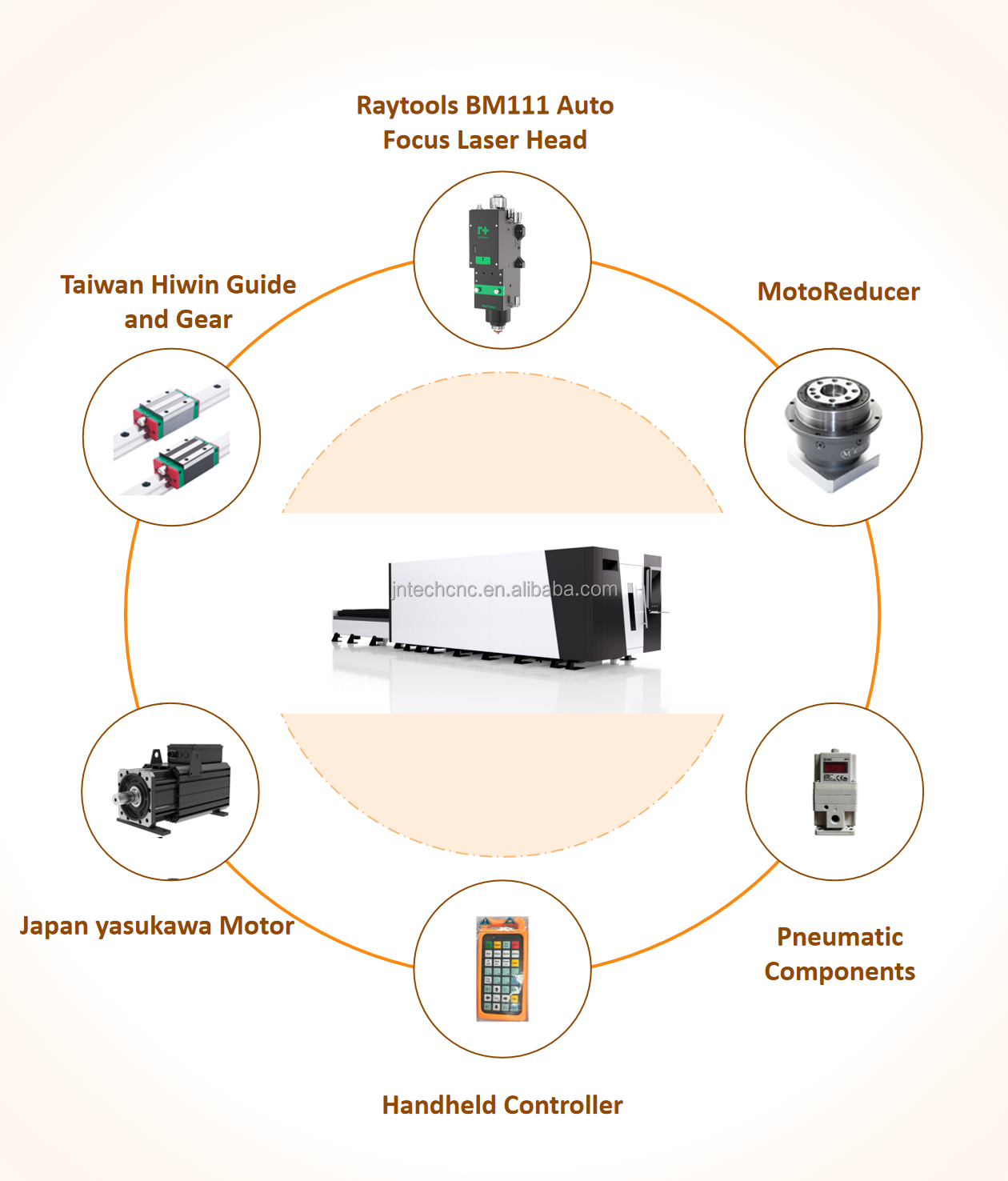

Rack and Gear:

-

Taiwan YYC Rack and HIWIN Gear

-

Lubrication:

-

Automatically Lubrication System

-

Drives and Motors:

-

INOVANCE bus servo motor (Y-axis 1.8KW, X-axis 850W, Z-axis 400W)

-

Fiber Laser Source:

-

MAX 6KW(prepared by customer)

-

Ball Screw:

-

TBI Ball screw

-

Electron Component:

-

France Schneider

-

Chiller:

-

Hanli dual temperature water cooler(prepared by customer)

-

Voltage:

-

380V 3Ph 50Hz/60Hz

-

Reducer:

-

Motoreducer

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

120m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

3000*1500mm

-

Cutting Thickness:

-

40mm

-

Control Software:

-

FSCUT 4000E

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jntech

-

Weight (KG):

-

6000 KG

-

Core Components:

-

laser

-

Electric Proportional Valve:

-

Japan SMC Electric Proportional Valve

-

Rack and Gear:

-

Taiwan YYC Rack and HIWIN Gear

-

Lubrication:

-

Automatically Lubrication System

-

Drives and Motors:

-

INOVANCE bus servo motor (Y-axis 1.8KW, X-axis 850W, Z-axis 400W)

-

Fiber Laser Source:

-

MAX 6KW(prepared by customer)

-

Ball Screw:

-

TBI Ball screw

-

Electron Component:

-

France Schneider

-

Chiller:

-

Hanli dual temperature water cooler(prepared by customer)

-

Voltage:

-

380V 3Ph 50Hz/60Hz

-

Reducer:

-

Motoreducer

Product Description

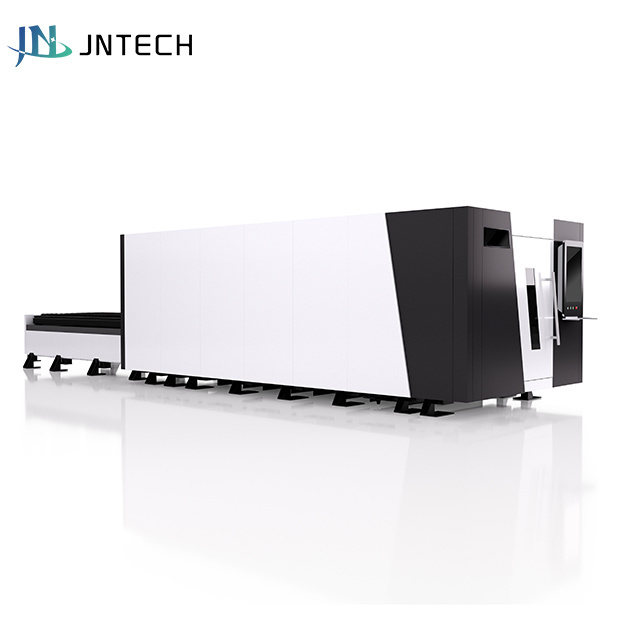

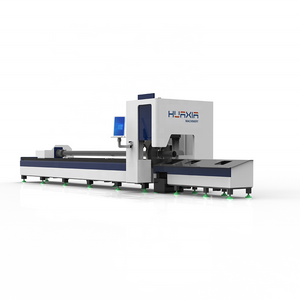

High Precision Fiber Laser Cutting System for Metal Advanced Laser Cutting Machines for Sale

Jntech fiber laser metal cutting machines range from 1kW up to our incomparable 12kW Plate and tube cutting laser reliable turnkey laser cutting system designed to meet low to medium volume production requirements of metal fabricators

Machine Application

Application Materials: Fiber Laser Cutting machine is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Software with strong function, capable to design sorts of shapes, letters for cutting with easy and convenient operation. Fiber laser metal cutting machine for metal cutting CNC metal sheet fiber laser cutting machine is widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, kitchen utensils and appliances, craft gifts, tool processing, decoration.

Advantage of High Precision Fiber Laser Cutting System for Metal Advanced Laser Cutting Machines

With a fully enclosed design;

The observation window adopts an European CE Standard laser protective glass;

The smoke produced by cutting can be filtrated inside, it's non-polluting and environmentally friendly;

The weight of machine is 7500kg;

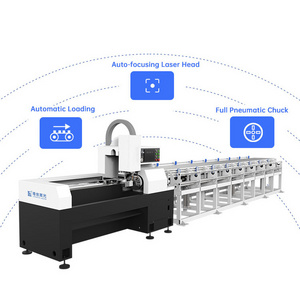

fiber laser cutting machine can not only cut metal plates, but also metal pipes. It has many uses and can save the space of more than 50%, which effectively improve productivity.

Specification

|

item

|

value

|

|

Application

|

LASER CUTTING

|

|

Applicable Material

|

Metal

|

|

Condition

|

New

|

|

Laser Type

|

Fiber Laser

|

|

Cutting Area

|

3000*1500mm

|

|

Cutting Speed

|

120m/min

|

|

Graphic Format Supported

|

AI, PLT, DXF

|

|

Cutting Thickness

|

40mm

|

|

CNC or Not

|

Yes

|

|

Cooling Mode

|

WATER COOLING

|

|

Control Software

|

FSCUT 4000E

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

Jntech

|

|

Laser Source Brand

|

MAX

|

|

Laser Head Brand

|

Raytools BM06K cutting head

|

|

Servo Motor Brand

|

Yaskawa

|

|

Guiderail Brand

|

HIWIN

|

|

Control System Brand

|

Cypcut

|

|

Weight (KG)

|

6000KG

|

|

Key Selling Points

|

High Productivity

|

|

Optical Lens Brand

|

Wavelength

|

|

Warranty

|

3 years

|

|

Applicable Industries

|

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

3 years

|

|

Mode of Operation

|

continuous wave

|

|

Configuration

|

3-axis

|

|

Products handled

|

Sheet Metal

|

|

Feature

|

Water-cooled

|

|

Electric Proportional Valve

|

Japan SMC Electric Proportional Valve

|

|

Rack and Gear

|

Taiwan YYC Rack and HIWIN Gear

|

|

Lubrication

|

Automatically Lubrication System

|

|

Drives and Motors

|

INOVANCE bus servo motor (Y-axis 1.8KW, X-axis 850W, Z-axis 400W)

|

|

Fiber Laser Source

|

MAX 6KW(prepared by customer)

|

|

Ball Screw

|

TBI Ball screw

|

|

Electron Component

|

France Schneider

|

|

Chiller

|

Hanli dual temperature water cooler(prepared by customer)

|

|

Voltage

|

380V 3Ph 50Hz/60Hz

|

|

Reducer

|

Motoreducer

|

Details Images

Plate welding bed

The host part of the machine tool is an essential part of the whole laser cutting machine, which realizes the cutting function and controls the cutting precision. It comprises five units: bed, beam, Z-axis device, and sheet metal protection.

The bed is welded by high-strength steel plates, which has a higher intensity than the welded square tube. The semi_x0002_hollow bed design is adopted, and the heating area is small to avoid bed deformation due to long-term high temperatures. It effectively guarantees the realization of long-term batch and stable cutting for users.

Samples

Packing & Delivery

1.The innermost layer is EPE pearl cotton film package.

2.The middle layer is wrapping up with environmental protection material.And the outermost layer is winding up with PE stretch film.

3.Plywood packing and steel strip outside fixed the box.

4. Finishing packing by normal container or frame container

Hot Searches