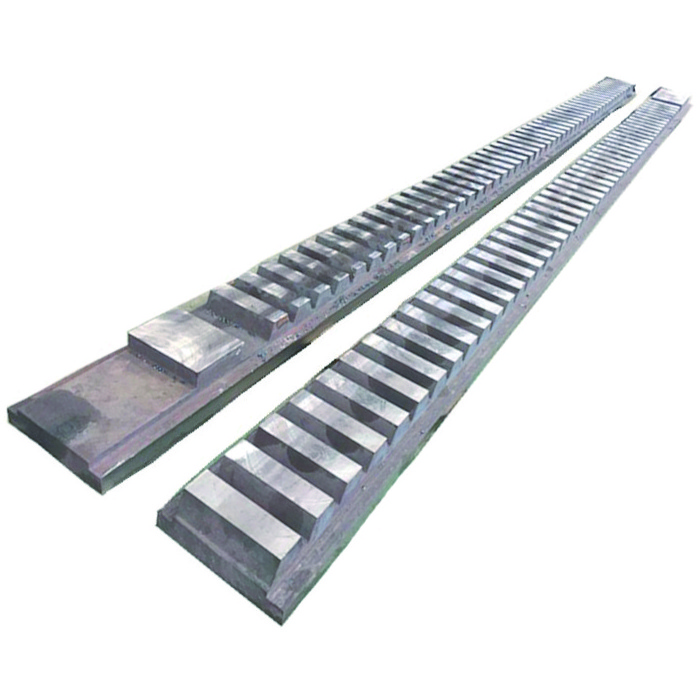

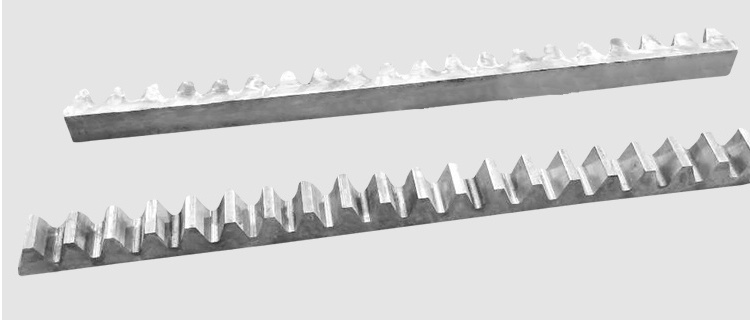

1.large module large size,Single rack maximum. processing size is up to 10000 mm.

2. high-precision,Assembling gearrack.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

gear rack

-

Application:

-

heavy-duty car,shoes machinery,port machinery etc

-

Surface treatment:

-

lathing ,grinding,milling and hobbing

-

Heat treatment:

-

quenching and tempering

-

Certificate:

-

ISO9001

-

Size:

-

Cutomized Size

-

Insepection:

-

raw material inspection, UT,physical property test,dimension inspect

-

Teeth Type:

-

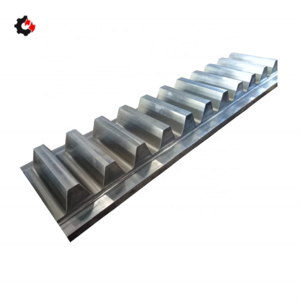

Straight Helical Teeth

-

MOQ:

-

1 Piece

-

Packing:

-

standard wooden box

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Brass, Stainless steel, Steel Alloys

-

Place of Origin:

-

China

-

Product name:

-

gear rack

-

Application:

-

heavy-duty car,shoes machinery,port machinery etc

-

Surface treatment:

-

lathing ,grinding,milling and hobbing

-

Heat treatment:

-

quenching and tempering

-

Certificate:

-

ISO9001

-

Size:

-

Cutomized Size

-

Insepection:

-

raw material inspection, UT,physical property test,dimension inspect

-

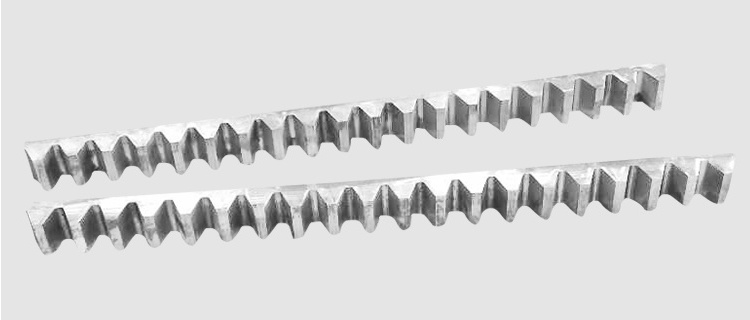

Teeth Type:

-

Straight Helical Teeth

-

MOQ:

-

1 Piece

-

Packing:

-

standard wooden box

Gear Rack selling points.

OEM Large Module Large Size Heavy Machining Gear Rack

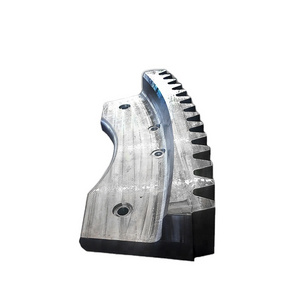

The rack is a special gear with teeth distributed on the strip body. The racks are also divided into straight racks and helical racks, which are paired with spur gears and helical gears, respectively; the tooth profile of racks is straight rather than involute (it is flat for tooth surfaces) The equivalent of the circle radius of the indexing cylinder is infinite.

Our company would supply large size Gear rack, mining rack,reduction box gear rack Non-standard rack, Marine rack, Helical rack, Round rack, Port machine rack, Heavy Duty Rack, Curved rack, Construction lift rack and Ny. etc.

Product application

Gear racks are mainly used in Engineering transport machinery, ports, mines transport , automatic loading and unloading truss robots, stacking robots, material handling devices, lifts. etc.

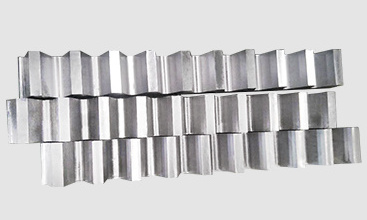

Gear rack is forged by a large-scale pneumatic hammer, the internal structure is dense, Flaw detection for internal cracks.

6m CNC gantry milling machine would be leaved 3-5mm allowance according to different materials.

Heat treatment to increase the hardness and strength of the workpiece.

Prevent deformation and prepare for further finishing.

Adopting Large-size C NC gantry milling for finishing, Accuracy is up to 0.01mm.

High-frequency quenching of the tooth surface is used to increases hardness and wear resistance.

Splicing and splitting to ensure product quality and ensure installation smoothly.

Standard export Packaging, Inner Wrap, then Plywood case.

YOGIE is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts according to customer's request, including shafts, gears, sprockets, mining machinery parts, weldings, bearings, castings and forgings etc.

The products are mainly used in the fields of mining, petroleum, cement, steel mill, power plant, sugar factory etc.

1. What is your terms of delivery?

A: FOB, CFR, CIF.

2. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

3. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery