- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

NONE

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TONTEN

-

Model Number:

-

T-LFC6

-

Product Name:

-

LFC Coating

-

Application:

-

foundry

-

Color:

-

yellow/grey

-

Feature:

-

Fast Dry

-

Type:

-

powder

-

Packing:

-

25kg plastic bags

-

Raw material:

-

zircon, corundum, graphite, high alumina, kyanite

-

Payment:

-

T/T

Quick Details

-

CAS No.:

-

NONE

-

Other Names:

-

ceramic investment

-

MF:

-

NONE, Mixture

-

EINECS No.:

-

NONE

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TONTEN

-

Model Number:

-

T-LFC6

-

Product Name:

-

LFC Coating

-

Application:

-

foundry

-

Color:

-

yellow/grey

-

Feature:

-

Fast Dry

-

Type:

-

powder

-

Packing:

-

25kg plastic bags

-

Raw material:

-

zircon, corundum, graphite, high alumina, kyanite

-

Payment:

-

T/T

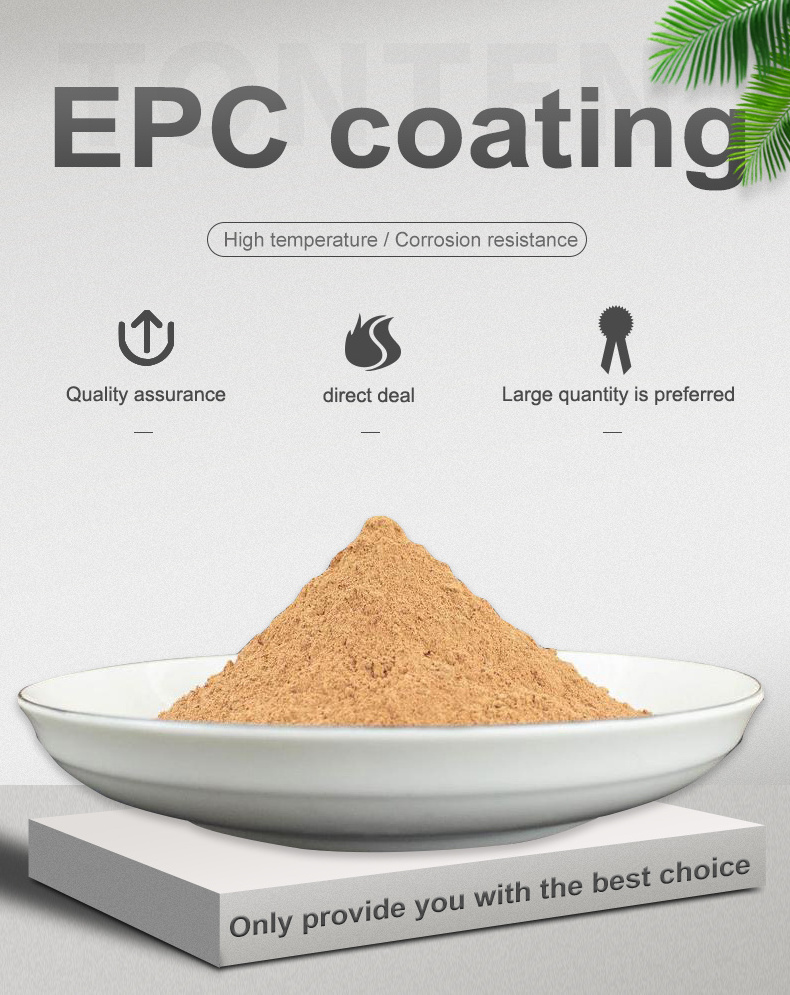

Binders for Paints LFC Coating Powder Binders

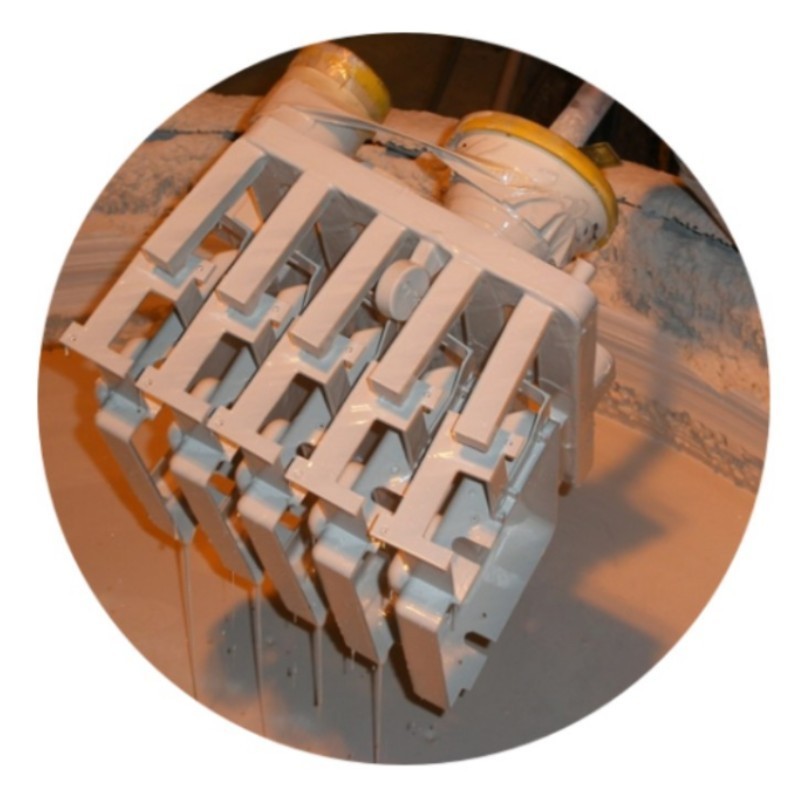

Water based EPC coatings for high-temperature high-strength brinders composite inorganic salt as the main raw material, it is a microporous mesh shape molecular structure, PH value of 7.0-8.0.

With this brinders formulated coating slurry coating having good sag resistance, leveling suspension, adsorption, air permeability, good wear resistance at room temperature and high temperature strength and high temperature resistant steel water erosion, crack sex.

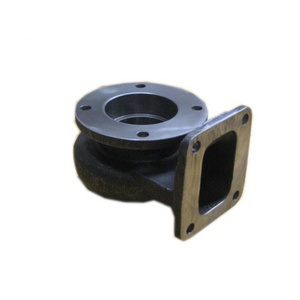

This brinders with a variety of aggregate (quartz, olivine, mullite, kyanite, alum stone, graphite, zircon, corundum, chromium ore), etc. equipped with, different materials suitable for the respective casting coating shelling smooth.

Directions

1, powder coating binder and aggregate used with a ratio of 1:10, add water, stir.

Coating binder: aggregate: water = 1: 10: 7 ------- ------ stirred for 30 minutes plus the amount of water to adjust the concentration ------ stirred for a further 20 minutes or more, or stand-by

2, the preparation of powder coatings in addition to aggregate and water, but do not add any other materials to be matched

3. cast iron aggregate added quartz powder (200 mesh) to the ratio of 1 kg 10 kg quartz powder binder is added. Shelling is good think can add aggregate quartz powder 50%, aluminum 50% higher.

High manganese steel pieces olivine powder can be added to the aggregate ratio of 1 kg binder is added 10 kg olivine powder (200 mesh)

Coating Requirements

The process according to the situation, generally brush 2-3 times. Low negative pressure of large thick pieces can brush 3 times, coating thickness 1.5-2mm better.

-brown paper bag or plastic woven bag -25kg (55lb)/bag, 40 bags packed in a 1000kg (2200lb) bulk bag. -25kg (55lb)/bag, 40 bags on a 1000kg (2200lb) pallet. -1000kg (2200lb)/jumbo bag. -Customized packing availble

CHENGQI MACHINERY Co, Ltd. They are three subsidiary companies of machinery and equipment, abrasives, refractories and water

treatment chemical products, integrating product design, R&D, production and sales, adopting international quality standards, with

years of sales experience at home and abroad.

successfully established a global sales network covering more than 30 countries in Europe, America, Asia, Africa and Australia,

etc.

We are specialized in production of Abrasives Material, Refractory Material, Filter Material, Wear Resistance Material, Chemical

Products etc. All of our products comply with international quality standards and are greatly appreciated in a variety of

different markets throughout the world.

1). Abrasive material: Brown fused alumina(BFA), White fused alumina, Garent, Ceramsite foundry sand, Quartz sand, Black silicon

carbide, Aluminum oxide, Ceramic sand, Glass Microsphere, Copper Slag, Walnut Shell, Corncob etc.

2). Refractory material: Light weight insulation brick, High alumina brick, refractory brick for pizza ovens , Castable, Bauxite

etc.

3). Filter Material: Quartz sand, Walnut shell, Ceramic grain filters etc.