Maanshan WILA CNC Machine Tools Co., Ltd is a modern professional Hi-Tech enterprise, specializing in R&D, manufacturing,marketing of METAL FABRICATION FORMING MACHINES and TOOLINGS.WILA CNC scopes of supply include:press brakes,metal shearing machine, hydraulic press, punching machine,iron worker, rolling machine, grooving machine, pipe

bending machine,fiber laser cutting machine, plasma cutting machine etc.

WILA CNC ’s business tenet: “Exist on Quality and Service”

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

wila

-

Dimension(L*W*H):

-

452mm*1065mm

-

Capacity:

-

115L

-

Weight:

-

800

-

Inner Material:

-

HDPE

-

Outer Material:

-

CARBON FIBER

-

Design Pressure(MPa):

-

20

-

Working Temperature(℃):

-

1 - 2 ℃

Quick Details

-

Volume (m³):

-

custom

-

Max Working Pressure(MPa):

-

5 MPa

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

wila

-

Dimension(L*W*H):

-

452mm*1065mm

-

Capacity:

-

115L

-

Weight:

-

800

-

Inner Material:

-

HDPE

-

Outer Material:

-

CARBON FIBER

-

Design Pressure(MPa):

-

20

-

Working Temperature(℃):

-

1 - 2 ℃

Product Description

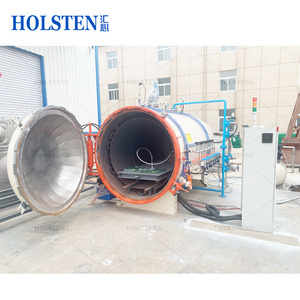

Carbon Fiber Autoclave

1.

Product Introduction:

The composite autoclave is a key equipment for hot-pressing shaping of carbon fibers and resin matrix composites. The quality of the product is obtained inside the autoclave reaching an increase of mechanical features up to 20-30% compared to other methods of polymerization.

The composite material autoclave mainly used to the composite materials military products,space vehicle by high temperature and high pressure.It also can be applied to strengthen the carbon fiber,glass fiber,boron fiber and ect.More over,it also can change the metallic/nonmetallic joint components,such as airplane door,fairing,airborne radar and so on.

2,

Product Features:

Automatic control technology combining PID and fuzzy control

New energy saving system optimization design technology

High temperature and high pressure static sealing completely closed variable frequency water-cooled motor

A new man-machine-pressure-temperature integrated safety interlock device

The optimum design of human pressure tank is carried out by finite element analysis

Unique composite insulation technology

Hydrodynamic simulation and design of annular duct

New energy saving system optimization design technology

High temperature and high pressure static sealing completely closed variable frequency water-cooled motor

A new man-machine-pressure-temperature integrated safety interlock device

The optimum design of human pressure tank is carried out by finite element analysis

Unique composite insulation technology

Hydrodynamic simulation and design of annular duct

2.

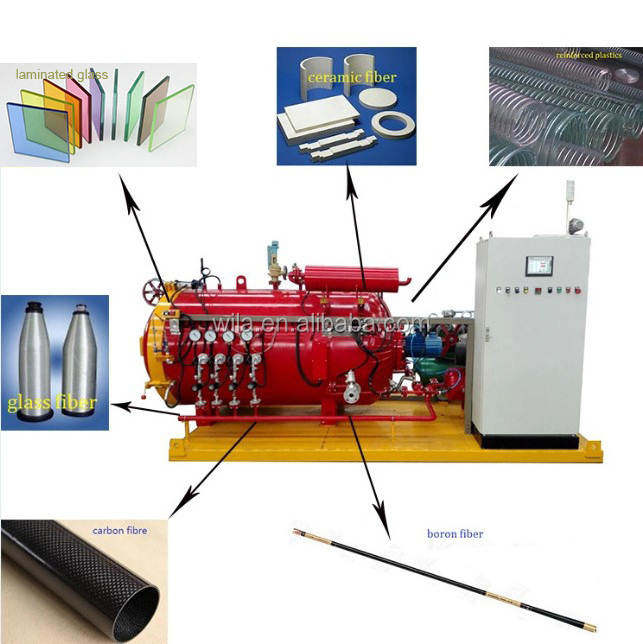

Application scope

Composite material processing Carbon fiber, boron fiber, laminated glass,aramid

fiber, glass fiber, metal composites, reinforced plastics and etc.. Widely used in aircraft, missiles, satellites and space shuttle, such as the airplane cabin door, fairing,airborne radar cover, the plane bracket, empennage.

fiber, glass fiber, metal composites, reinforced plastics and etc.. Widely used in aircraft, missiles, satellites and space shuttle, such as the airplane cabin door, fairing,airborne radar cover, the plane bracket, empennage.

1.Widely used in composite material processing Carbon fiber, boron fiber, laminated glass,aramid fiber, glass fiber, metal composites, reinforced plastics and etc

2.widely used in aerospace,weapons,electronic industry fields

3.widely used in rail transportation and automotive industry fiels

We provide

Autoclaves

for different applications

Basic Data

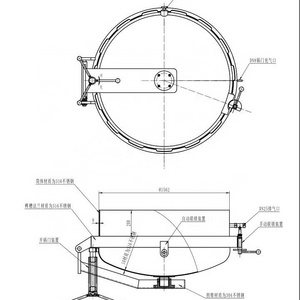

1. Model and Size of the Composite Autoclave

Ø Autoclave model: OL-CO0608

Ø Effective diameter: 600mm

Ø Effective length: 800mm

2. Production Performance

Ø Product size: max. 600mm x800mm

3. Electric Power

Ø Operating Voltage: 220/380VAC, 3P+N+PE, 50/60Hz

Ø Control Power: 220VAC/50Hz/24VDC

4. Water and Air supply:

Ø Cooling water consumption: ~2m3/h

Ø Cooling water pressure: min.3 bar ~ max. 6 bar

Ø Control air of control equipment: 5 ~ 7bar

Ø Max. Air source for Autoclave: 15 bar

General feature and working process of the autoclave

General feature

OLYMSPAN Autoclave is a sealed pressure vessel which can be heated by a forced convection heating unit, where temperature,

pressure and vacuum can be controlled effectively. By means of an advanced design, consisting of a forced convection fun and motor

unit, output heating power system can be adjusted 0-100%,proportional control of the pressurization, cooling and exhaust

components. It can obtain an uniform temperature and pressure according to the process curve. Temperature is check in heating,

keeping, and cooling phase. The heating/cooling gradients can be set by operator. Pressure is adjusted in pressurization, keeping,

release phase.

Working process

The whole working process of OLYMSPAN Autoclave has 17 segments .In each segment, the value of temperature, pressure, vacuum and

segment time can be set and monitored by HIM and PC, and the operation process will be realized by our exclusively developed software which is based on PLC control system to ensure the full automatic operation.OLYMSPAN Autoclave is suitable for manufacturing various composite materials, and it also can guarantee the perfect product quality.

Ø Autoclave model: OL-CO0608

Ø Effective diameter: 600mm

Ø Effective length: 800mm

2. Production Performance

Ø Product size: max. 600mm x800mm

3. Electric Power

Ø Operating Voltage: 220/380VAC, 3P+N+PE, 50/60Hz

Ø Control Power: 220VAC/50Hz/24VDC

4. Water and Air supply:

Ø Cooling water consumption: ~2m3/h

Ø Cooling water pressure: min.3 bar ~ max. 6 bar

Ø Control air of control equipment: 5 ~ 7bar

Ø Max. Air source for Autoclave: 15 bar

General feature and working process of the autoclave

General feature

OLYMSPAN Autoclave is a sealed pressure vessel which can be heated by a forced convection heating unit, where temperature,

pressure and vacuum can be controlled effectively. By means of an advanced design, consisting of a forced convection fun and motor

unit, output heating power system can be adjusted 0-100%,proportional control of the pressurization, cooling and exhaust

components. It can obtain an uniform temperature and pressure according to the process curve. Temperature is check in heating,

keeping, and cooling phase. The heating/cooling gradients can be set by operator. Pressure is adjusted in pressurization, keeping,

release phase.

Working process

The whole working process of OLYMSPAN Autoclave has 17 segments .In each segment, the value of temperature, pressure, vacuum and

segment time can be set and monitored by HIM and PC, and the operation process will be realized by our exclusively developed software which is based on PLC control system to ensure the full automatic operation.OLYMSPAN Autoclave is suitable for manufacturing various composite materials, and it also can guarantee the perfect product quality.

Company Introduction

WILA CNC Machine Tools Inc.

WILA CNC machine tools is located in Ma’anshan City, Anhui Province, Yushan District, Xiangshan Indutrial Park with self-built plant, covers an area of 6.6 million square meters. Registered capital of 30 million yuan. We specialize in producing all kinds of metal fabrication machines such as press brakes, shears, hydraulic presses, iron worker, rolling machines, punching machines, laser cutting machine, CNC machine tools.With over 12 years of bending machines and plate shearing machine design and production experience. The company has more than 150 employees and 12 R & D personnel, the introduction of international advanced equipment and technology production equipment, continuous R & D and innovation, implementation of modern enterprise management mode, to provide customers with high-quality

machinery and machine tools. Our products sell well in Europe, America, South America, Africa, Southeast Asia, more than 70 countries and regions. WILA-CNC stuff committed to further cooperation with global customers on a win-win business.

machinery and machine tools. Our products sell well in Europe, America, South America, Africa, Southeast Asia, more than 70 countries and regions. WILA-CNC stuff committed to further cooperation with global customers on a win-win business.

Our India Branch:

Tina Zhao

Email:sales1@wilacnc.com

Whatsapp NO:+8613956232507

Wechat/phone:+8613956232507

http://www.wilacnc.com

Email:sales1@wilacnc.com

Whatsapp NO:+8613956232507

Wechat/phone:+8613956232507

http://www.wilacnc.com

Hot Searches