Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

cloudchem

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

cloudchem

-

Model Number:

-

AB group

-

Product Name:

-

SPUA

-

Application:

-

anti-explosion anti-corrosion coating

-

Color:

-

Customized Colors

-

Keywords:

-

Spray Polyurea Elastomer

-

Type:

-

AB group

-

Feature:

-

anti-explosion

-

Name:

-

Polyurea Elastomer high strength paint

-

Main components:

-

polyurea

-

Appearance:

-

Liquid Viscous Paint

-

Package:

-

200 Kg/ Barrel

Quick Details

-

CAS No.:

-

Spray Polyurea Elastomer

-

Other Names:

-

SPUA

-

MF:

-

high strength coating

-

EINECS No.:

-

cloudchem

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

cloudchem

-

Model Number:

-

AB group

-

Product Name:

-

SPUA

-

Application:

-

anti-explosion anti-corrosion coating

-

Color:

-

Customized Colors

-

Keywords:

-

Spray Polyurea Elastomer

-

Type:

-

AB group

-

Feature:

-

anti-explosion

-

Name:

-

Polyurea Elastomer high strength paint

-

Main components:

-

polyurea

-

Appearance:

-

Liquid Viscous Paint

-

Package:

-

200 Kg/ Barrel

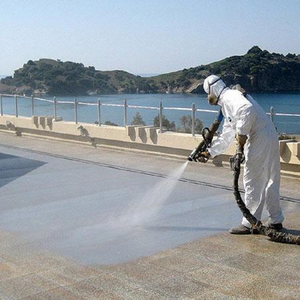

Spraying polyurethane elastomer technology with 100% solid content was successfully developed in North America in the 1970s. At present, it has become one of the most widely used anti-corrosion coating technologies in North America, which represents the development direction of the coating industry in the 21st century and has a successful application history of more than 30 years all over the world. In 1997, Marine chemical researchers in China introduced key spraying equipment and developed SPUA technical formula and construction technology with independent intellectual property rights. After more than 20 years of development, spraying polyurethane technology has made great progress in China. The application scope of 100% solid content polyurethane anticorrosion coating covers many fields such as pipeline anticorrosion, chemical tank anticorrosion, drinking water and industrial sewage system, oil and gas industrial system, port and wharf facilities, etc. With the continuous expansion of application scope and the success of application practice, 100% solid polyurethane anticorrosive coating has been trusted by more and more customers.

Ⅱ. Advantages

Ø Fast curing, a few seconds gel, facade, surface continuous spray flow.

Ø insensitive to humidity/temperature, no foam, has a very wide temperature adaptability, can be in normal curing to 40 ℃ to 65 ℃ .

Ø 100% solid content, no volatile organic compounds, no combustible materials, in line with the requirements of environmental protection, construction process safety is guaranteed.

Ø No amine, coal tar and other toxic substances, the construction process will not cause pollution to the environment, harmless to the human body.

Ⅲ . Properties

1. The adhesion

Spraying polyurea material has good adhesion to metal, concrete, plastic, wood and other substrates. Through proper formula selection, a system with adhesion strength exceeding its own strength can be obtained. In the pipeline anticorrosion application, the pipeline anticorrosion material does not need the supporting primer, but can be directly sprayed on Sa2.5 grade sandblasted steel, with the adhesion greater than 15Mpa. As can be seen from the table, some substrates have been pulled out, which indicates that the adhesion between the sprayed polyurea material and the substrates is very good.

Adhesion of sprayed polyurethane to various substrates

|

substrate |

Aromatic |

aliphatic |

|

Concrete(without primer) |

2.8 |

2.8 |

|

concrete (with primer) |

6.8 |

6.9 |

|

Steel

|

18 |

10 |

|

aluminum |

13.7 |

--- |

|

plywood |

1.7 |

1.7 |

2. Wear resistance

According to the laboratory to its abrasion performance determination, spray polyurethane anticorrosive coating wear resistance is 5 to 7 times of ordinary natural rubber, is 10 times more than carbon steel. The material not only has high strength, but also has good buffering and energy absorption performance. Spraying polyurethane anticorrosive coating has strong wear resistance, which determines that it can be widely used in the operation of rough stone belt, the external anticorrosion of pipeline crossing, high flow rate and high abrasion.

3. Media resistance

Spray polyurethane material compact, continuous, no joints, effectively prevent the invasion of external corrosion media, corrosion performance is very prominent. In addition to dimethyl formamide, methylene chloride, hydrofluoric acid, sulfuric acid, nitric acid and concentrated phosphoric acid strong dissolution, strong corrosive medium, for the most part it resists corrosion medium long-term immersion (25 ℃ ).

Dielectric resistance of spray polyurethane

|

Media |

Soak result |

Media |

Soak result |

|

acetic acid (10%) |

good |

ammonium nitrate |

good |

|

hydrochloric acid (10%) |

good |

gasoline |

good |

|

sulfuric acid (20%) |

good |

diesel |

good |

|

phosphoric acid(10%) |

good |

kerosene |

good |

|

citric acid |

good |

crude oil |

good |

|

lactic acid |

Good Slight discoloration |

hydraulic oil |

good |

|

sodium hydroxide(20%) |

Good |

antifreeze agent |

good |

|

Sodium hydroxide (50%) |

Good Slight discoloration |

xylene |

Good Slight discoloration |

|

potassium hydroxide (10%) |

good |

n-hexane |

good |

|

potassium hydroxide (20%) |

Good, Slight discoloration |

carisoprodol |

good |

|

ammonium hydroxide |

good |

|

|

4. Salt spray resistance

Common pipeline anticorrosive materials such as epoxy powder fused with salt spray resistance test generally do not exceed 500 hours, the actual service life of less than 20 years. As the coating of polyurethane material is dense, continuous and without joints, its salt spray resistance is very good. Spray polyurea material after 10,000 hours of salt spray test, the results show that: even the thinnest 1mm coating, there is no corrosion phenomenon, its buried service life can be up to 50 years.

5. Outdoor aging resistance

Spraying polyurethane material has excellent aging resistance. Although in the aromatic spray polyurethane material, there will be yellowing phenomenon, but not pulverization and cracking. Aromatic polyurethane spray materials after 50 ℃ , 3871 hours of artificial accelerated ageing of the retention of physical properties such as before and after the experiment

Comparison of LD50 value polyurethane & amine cured epoxy resin

|

product |

LD50 ( mg/kg ) |

|

|

polyurethane (PU) |

polymeric MDI |

5000-10000 |

|

polyhydric alcohols |

2000-5000 |

|

|

amine cured epoxy resin |

amine |

500-4000 |

|

epoxy resin |

≤2000 |

|