- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China, JIA

-

Brand Name:

-

WD

-

Product name:

-

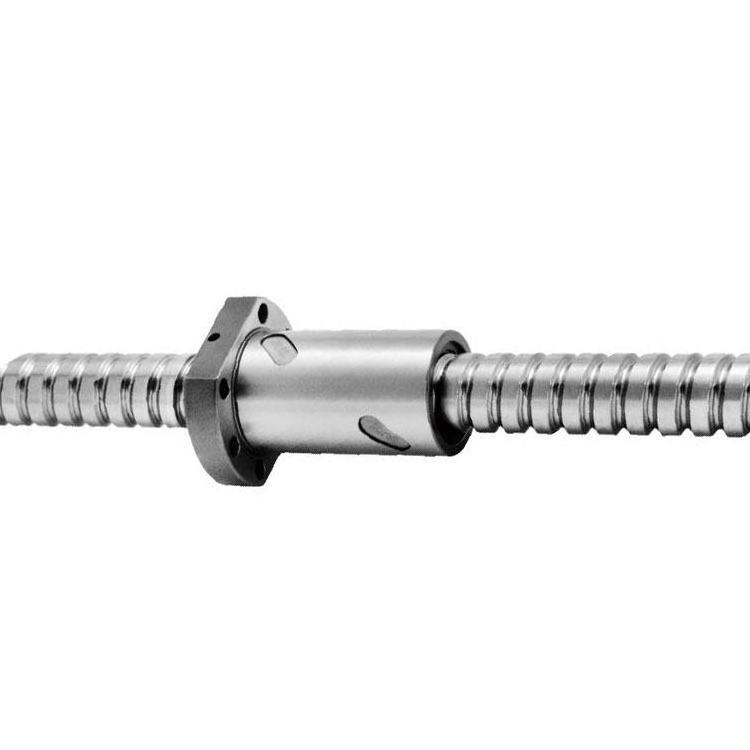

High Precision Ball Screw

-

Application:

-

Cnc Machining Parts

-

Nut type:

-

Single Nut$ Double Nut

-

Feature:

-

High Transmission Efficiency

-

Diameter:

-

10mm/12mm/16mm/20mm/25mm/32mm/40mm/50mm

-

Performance:

-

High Speed High Precision

-

Keyword:

-

Ball Screw Beairng

-

Grade:

-

C7.C5.C3

Quick Details

-

Weight (KG):

-

10

-

Material:

-

cr15 steel

-

Length:

-

300mm

-

Place of Origin:

-

China, JIA

-

Brand Name:

-

WD

-

Product name:

-

High Precision Ball Screw

-

Application:

-

Cnc Machining Parts

-

Nut type:

-

Single Nut$ Double Nut

-

Feature:

-

High Transmission Efficiency

-

Diameter:

-

10mm/12mm/16mm/20mm/25mm/32mm/40mm/50mm

-

Performance:

-

High Speed High Precision

-

Keyword:

-

Ball Screw Beairng

-

Grade:

-

C7.C5.C3

Factory Description

Size Information

|

SFU series ball screw specification

|

|

|

|

|

|

|

||||||

|

SFU1204

|

SFU1604

|

SFU1605

|

SFU1610

|

SFU2004

|

SFU2005

|

SFU2504

|

||||||

|

SFU2505

|

SFU2506

|

SFU2508

|

SFU2510

|

SFU3204

|

SFU3205

|

SFU3206

|

||||||

|

SFU3208

|

SFU3210

|

SFU4005

|

SFU4006

|

SFU4008

|

SFU4010

|

SFU5010

|

||||||

|

SFU5020

|

SFU6310

|

SFU6320

|

SFU8010

|

SFU8020

|

|

|

||||||

|

DFU series ball screw specification

|

|

|

|

|

|

|

||||||

|

DFU1604

|

DFU1605

|

DFU1610

|

DFU2004

|

DFU2005

|

DFU2504

|

DFU2505

|

||||||

|

DFU2506

|

DFU2508

|

DFU2510

|

DFU3204

|

DFU3205

|

DFU3206

|

DFU3208

|

||||||

|

DFU3210

|

DFU4005

|

DFU4006

|

DFU4008

|

DFU4010

|

DFU5010

|

DFU5020

|

||||||

|

DFU6310

|

DFU6320

|

DFU8010

|

DFU8020

|

|

|

|

||||||

|

ball screw end supports specification

|

|

|

|

|

|

|

||||||

|

BKBF12

|

BKBF15

|

BKBF17

|

BKBF20

|

BKBF25

|

BKBF30

|

|

||||||

|

ball screw nut housings specification

|

|

|

|

|

|

|

||||||

|

DSG16H

|

DSG20H

|

DSG25H

|

DSG32H

|

|

|

|

||||||

|

Precision grade

|

Model

|

diameter

|

lead/pitch

|

length

|

|

C7

|

SFU1204

|

12mm

|

4mm

|

as per demand

|

|

C7

|

SFU1605

|

16mm

|

5mm

|

as per demand

|

|

C7

|

SFU1610

|

16mm

|

10mm

|

as per demand

|

|

C7

|

SFU2005

|

20mm

|

5mm

|

as per demand

|

|

C7

|

SFU2020

|

20mm

|

20mm

|

as per demand

|

|

C7

|

SFE2040

|

20mm

|

40mm

|

as per demand

|

|

C7

|

SFU2505

|

25mm

|

5mm

|

as per demand

|

|

C7

|

SFU2510

|

25mm

|

10mm

|

as per demand

|

|

C7

|

SFU3205

|

32mm

|

5mm

|

as per demand

|

|

C7

|

SFU3210

|

32mm

|

10mm

|

as per demand

|

|

C7

|

SFU4005

|

40mm

|

5mm

|

as per demand

|

|

C7

|

SFU4010

|

40mm

|

10mm

|

as per demand

|

|

C7

|

SFU5005

|

50mm

|

5mm

|

as per demand

|

|

C7

|

SFU5010

|

50mm

|

10mm

|

as per demand

|

|

C7

|

SFU6310

|

63mm

|

10mm

|

as per demand

|

Products Description

|

Item Name

|

China Wholesale Stainless Steel CNC Lead Screw Rotating Nut 20mm Ball Screw Cnc Linear Guide Ground Ballscrew 1605 Ball Screw

|

|

|

|

|||

|

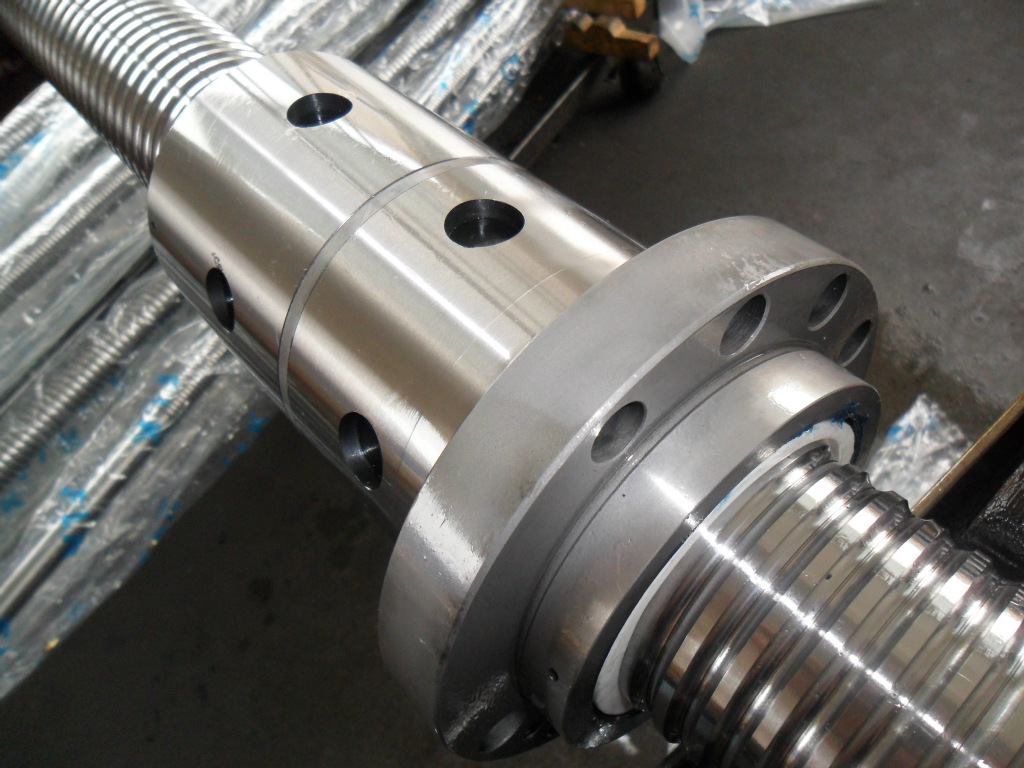

Material

|

Bearing steel, alloy steel, GCr15,etc

|

|

|

|

|||

|

Grade

|

C7, C5, C3 for ball screw with external or internal return tube

|

|

|

|

|||

|

Length

|

From 10mm to 10000mm for ball screw with external or internal return tube, can be customized based on customers requirement

|

|

|

|

|||

|

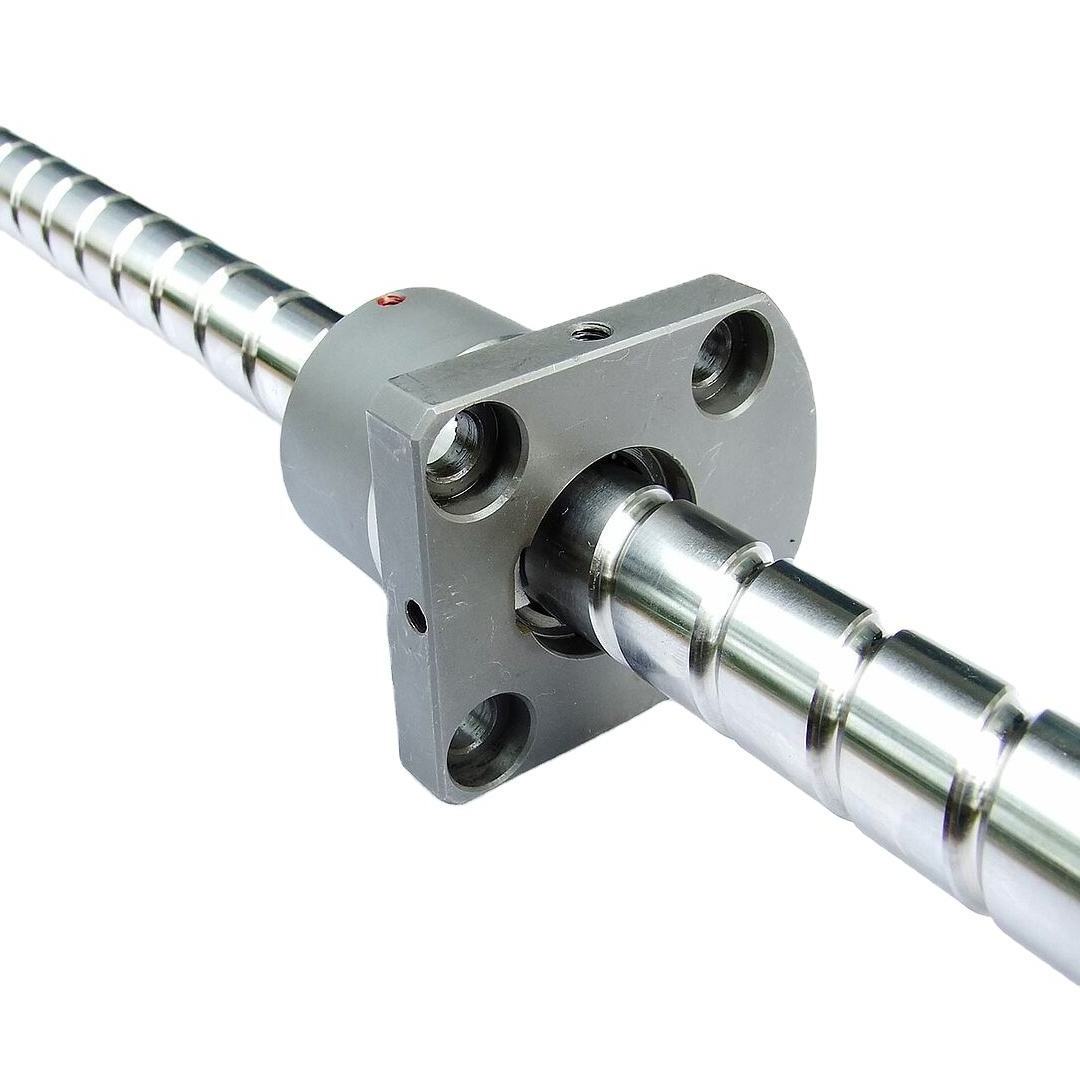

Flange Type

|

No cutting, Single Cutting, Double Cutting

|

|

|

|

|||

|

Nut type

|

Single or double nuts

|

|

|

|

|||

|

Produce Code

|

Ground, Rolled for ball screw with external or internal return tube

|

|

|

|

|||

|

Production Process

|

Cold Rolling, CNC Grinding, Whirling Milling

|

|

|

|

|||

|

Feature

|

High stiffness

High efficiency High load & speed High Precision & low noise |

|

|

|

|||

|

Application

|

CNC machine, 3D printing machinery, chemical machinery, woodworking machinery, engraving machines, window machines, high speed machinery, semi-conductor equipment, robot, railways, automation application and etc

|

|

|

|

|||

|

Our Services

|

Custom ball screw with external return tube based on drawings or samples

|

|

|

|

|||

|

Delivery Time

|

3 days for sample order, bulk order need to be negotiated

|

|

|

|

|||

Ball screw according to GB classification there are P class and T class, that is, transmission class and positioning class, the accuracy level has 1, 2, 3, 4 ..... Several kinds, foreign products generally do not distinguish transmission or positioning, all to C0 ~ C10 or specific values. In general, general-purpose machinery or ordinary CNC machinery selected C7 (any 300 stroke within the positioning error ± 0.05) or below, high-precision CNC machinery selected C5 (± 0.018) above C3 (± 0.008) below, optical or detection machinery selected C3 above.

Products Exhibition

Ball screw bearing specifications selection

(1) Determine the positioning accuracy;

(1) Determine the positioning accuracy;

(2) Determine the lead of the ball screw bearing by the motor and the speed requirement;

(3) Check the nut size to determine the stroke and related data of the shaft end of the screw bearing; (4) Determine the average axial force and speed by load and speed distribution (acceleration and deceleration); (5) Determine the pre-pressure from the average axial force;

(3) Check the nut size to determine the stroke and related data of the shaft end of the screw bearing; (4) Determine the average axial force and speed by load and speed distribution (acceleration and deceleration); (5) Determine the pre-pressure from the average axial force;

(6) Determine the dynamic load rating by life expectancy, axial load and speed;

(7) Determine the outer diameter of the screw bearing and the nut form by the basic dynamic load rating, lead, critical speed, and DmN value limit;

(8)The outer diameter, nut, preload, and load determine the rigidity (machine design);

(9) Ambient temperature, total length of the nut to determine the thermal variation and cumulative lead; (10)Screw bearing rigidity, thermal variation position to determine the pre-tension;

(11)Maximum machine speed, temperature rise time, and screw bearing specifications determine motor drive torque and specifications.

Product packaging

Wooden case & Paper boxes

Choose the paper boxes to pack the mini ball screw first , the packed by the wooden cases outside , use the shrink film or the foam to pack products first

FAQ

1. How can we ensure our product quality? A:1, After order confirmed, we have a meeting with the main peoples who work for the workshop before production, investigate all the workmanship and some technical problems, ensure all of them have related ways to settle and control.

2, Inspect all the materials when arrived, ensure they will be catch up customers' requirements.

3, Inspect the semi-finished goods.

4, Inspect the finished products.

5, Final inspection when packing up all the goods. if there are not any problems for this step, our QC will issue the inspection report and release these products.

2, Inspect all the materials when arrived, ensure they will be catch up customers' requirements.

3, Inspect the semi-finished goods.

4, Inspect the finished products.

5, Final inspection when packing up all the goods. if there are not any problems for this step, our QC will issue the inspection report and release these products.

2. How about your productivity?A: We have factories in China, Chengdu, Chongqing, and Shenzhen, which are strong enough to guarantee our customers' quality and timeliness.

3. What are the terms of payment?A: Payment terms: Paypal, Western Union, Offshore Account or as your requirement. Payment terms are flexible for us in accordance with specific conditions. Generally, we advise a 30% TT deposit, balance is paid before shipment.

4. What will you do after-sales ?A: When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help.

Contact

Name : Eric

Email: sales@wanda-bearing.com

Whatsapp:+86 13182956277

Hot Searches